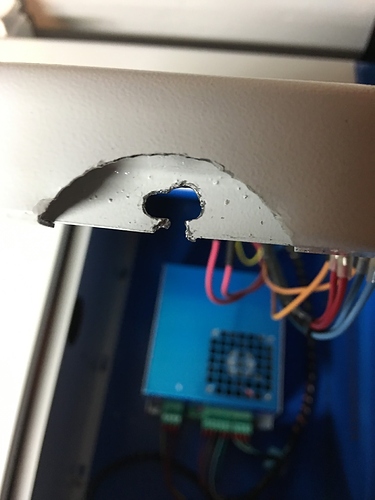

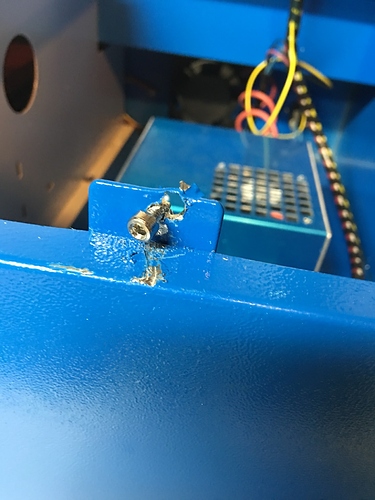

So I have had a rough start with my k40. First I had screws holding the panels down stripped so bad I had to drill them out. The I got to cut my first piece and noticed that the laser stopped cutting half way through after some tinkering I realized the mirrors where not aligned so as it was cutting the laser was missing the lens. Then after all that I saw some damage to the casing that I am afraid will cause the whole machine to be out of Wack. Fun times getting started!

I have my machine screwed down to a sheet of 3/4" MDF. It really helps keep things aligned, adds weight and gives you a stable, flat bottom to support items on.

I am so sorry to see this Corey. I was rooting for ya the whole time (especially after I made you nervous about ordering it). It took me a while to crack mine open too. I didn’t drill out the screws but I had to run a couple hardware store trips to get it open. That said, once you get everything going you are going to be amazed

@Ben_Walker I have done a few practice cuts and worked ok my mirrors or off so as the laser gets about half way over the bed the the beam miss aligns and stops cutting

I got my light objects air assist in today and plan on cutting back the exhaust this weekend to fit a bigger piece of material on the bed

Mines is the same I cant get either of the packing screws out and dont want to break the laser tube if a bit falls back  dont know what to do next

dont know what to do next  feel deflated and I aint started!

feel deflated and I aint started!

Its the same on laser tube area too, i am a little bit anxious about drilling that area in particular!