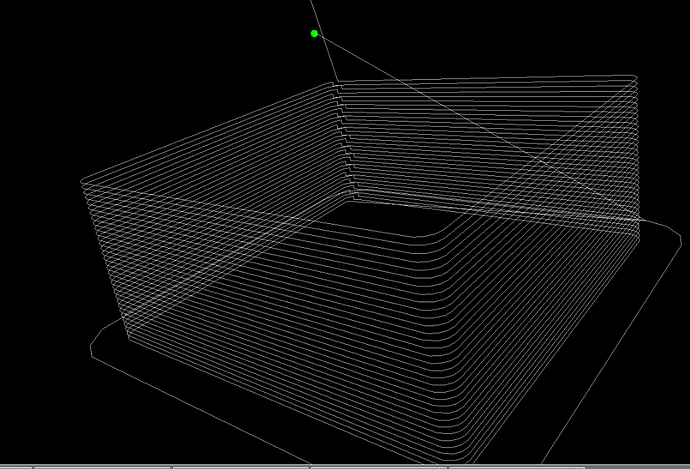

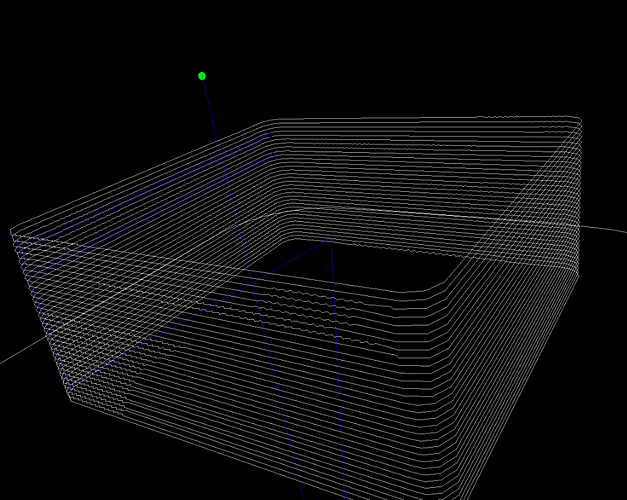

So I decided to try Slic3r and I used the thin wall stl(http://reprap.org/wiki/Calibration) to try it out. I got some strange results so I loaded the gcode in to a viewer. The picture to the left is generated using skeinforge and the other Slic3r. The skeinforge is smooth with a smooth speed throughout the print. In the Slic3r the speed changes alto resulting in holes in the print. I can’t see what’s causing it. It also has some ripples in some layers. Any ides on what’s going on? The pattern in the lower left corner on the Slic3r gcode picture are clearly seen in the print but I don’t understand way it is generated like that.

generated by Slic3r 0.9.8 on Sat Jan 19 19:49:34 2013

bed_size = 200,200

bed_temperature = 0

bottom_solid_layers = 3

bridge_fan_speed = 100

bridge_flow_ratio = 1

bridge_speed = 55

brim_width = 0

complete_objects = 0

cooling = 0

default_acceleration = 0

disable_fan_first_layers = 1

duplicate = 1

duplicate_distance = 6

duplicate_grid = 1,1

end_gcode = M104 S0 ; turn off temperature\nG28 X0 ; home X axis\nM84 ; disable motors

external_perimeter_speed = 100%

extra_perimeters = 1

extruder_clearance_height = 20

extruder_clearance_radius = 20

extruder_offset = 0x0

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width = 0

fan_always_on = 0

fan_below_layer_time = 60

filament_diameter = 1.75

fill_angle = 45

fill_density = 0.2

fill_pattern = rectilinear

first_layer_bed_temperature = 55

first_layer_extrusion_width = 200%

first_layer_height = 0.4

first_layer_speed = 35%

first_layer_temperature = 200

g0 = 0

gap_fill_speed = 20

gcode_arcs = 0

gcode_comments = 0

gcode_flavor = reprap

infill_acceleration = 0

infill_every_layers = 1

infill_extruder = 1

infill_extrusion_width = 0

infill_speed = 55

layer_gcode =

layer_height = 0.3

max_fan_speed = 100

min_fan_speed = 35

min_print_speed = 10

min_skirt_length = 0

notes =

nozzle_diameter = 0.5

only_retract_when_crossing_perimeters = 0

output_filename_format = [input_filename_base].gcode

perimeter_acceleration = 0

perimeter_extruder = 1

perimeter_extrusion_width = 0

perimeter_speed = 30

perimeters = 3

post_process =

print_center = 100,100

randomize_start = 1

retract_before_travel = 2

retract_length = 1.8

retract_length_toolchange = 10

retract_lift = 0

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 30

rotate = 0

scale = 1

skirt_distance = 6

skirt_height = 1

skirts = 1

slowdown_below_layer_time = 15

small_perimeter_speed = 30

solid_fill_pattern = rectilinear

solid_infill_below_area = 70

solid_infill_every_layers = 0

solid_infill_speed = 55

start_gcode = G28 ; home all axes

support_material = 0

support_material_angle = 0

support_material_extruder = 1

support_material_extrusion_width = 0

support_material_pattern = rectilinear

support_material_spacing = 2.5

support_material_speed = 60

support_material_threshold = 45

temperature = 190

threads = 2

toolchange_gcode =

top_solid_infill_speed = 50

top_solid_layers = 3

travel_speed = 60

use_relative_e_distances = 0

vibration_limit = 0

z_offset = 0

Perhaps you should report this as an issue on the slic3r github page. The developers are very active there, and if it’s a bug they’ll be keen to fix it.

It almost looks like slic3r is putting infill at those spots - they look like 45° zigzags to me. Try changing your infill angle to 0°? Even if that doesn’t fix it, it looks like a bug.

Slic3r is known to have problems with single-wall objects. They’ve never quite solved it entirely. Objects that are solid, and you set to have 1 perimeter, and no infill…work great. Objects that are modeled and the model itself is only a single nozzle thickness, tend to screw up like this.

Thanks. I’ll take a look at there trouble reports and see if anything fits.