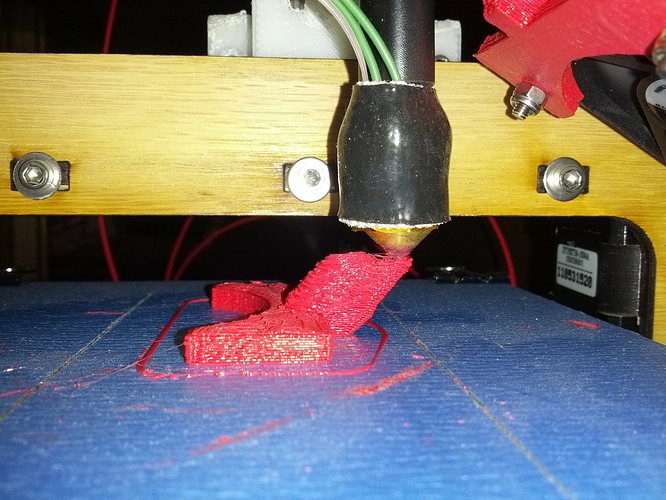

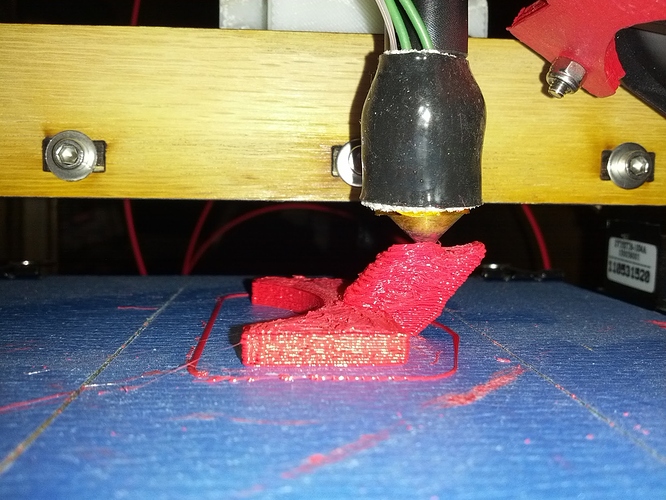

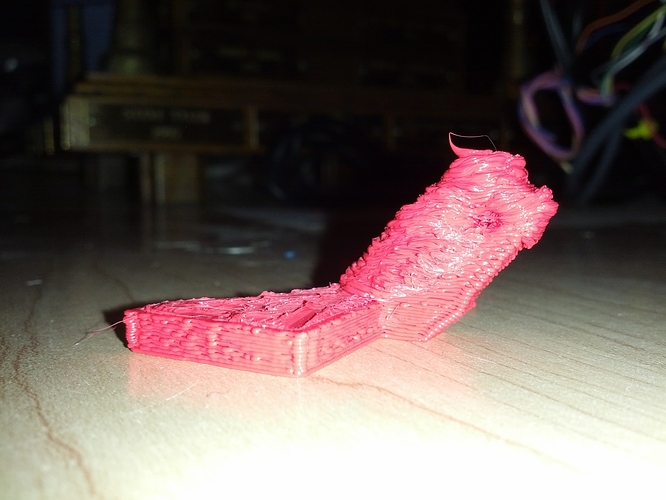

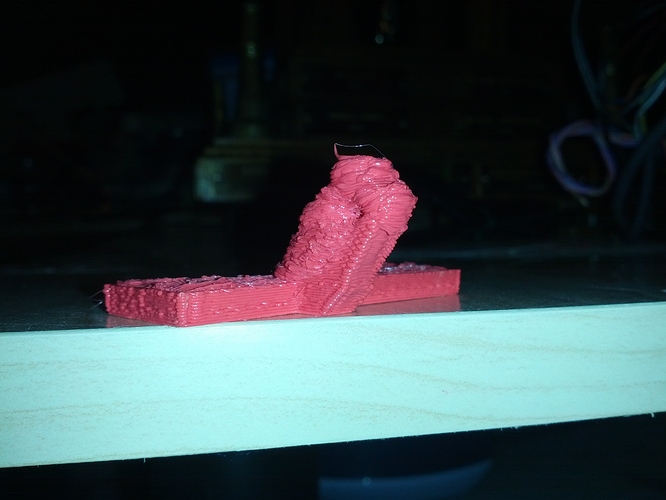

So I decided it was time to start 3d printing again. I printed out a fan support for my Mosaic printer whihc is helping a lot in creating thin walls and overhangs, but I have a new problem. I am getting “blobbing” and/or too much infill… so the hot end ends up pushing around the melted filament. You can see in the final prints how its all pushed to the front, almost like it is pushing to much filament through. Any thoughts on how to fix this? I am at a loss. Thanks for the help.

I would print more than one and position them about 20 mm apart. That way the plastic has time to cool between layers. You could also lower your temp a bit.

Not an expert opinion but it looks like too much is being extruded to start with. Have you checked the filament diameter and the settings for it ?

Looking at the infill at the top of that, I’d have to agree with @William_Frick 's excellent observation. Too much filament is being extruded and you can tell that the nozzle is dragging through it. In order to fix it, you can adjust filament diameter in your slicer, or you can correct e-steps-per-mm if your filament diameter is correct.

Double check that your Z motor is getting enough power. I found that at lower thickness levels that stepper motors would “skip” certain positions. For instance I could go from 0 to 1mm just fine, but going from 0.14mm to 0.25mm the head wouldn’t move. The next move that was 0.36mm it did move.

So it ended up double printing certain layers. It was a tough problem to catch. I had to hand create some gcode files to make the problem visible.

This was on a MakerGear Mosaic (M1) so I’m assuming you could have the same problem.

Make sure you unplug the power and usb before messing with the power settings on your Z axis stepper controller.

Definitely a problem with your e-steps-per-mm setting or filament diameter. Have you gotten an accurate measurement of your filament diameter? You can’t just put 1.75mm in there, as most filament varies . Also, you need to make sure your e-steps-per-mm is right, which too much filament coming out would indicate that your setting is too low (if filament diameter is correct). There are guides out there for how to accurately measure your proper e-steps per mm setting and filament diameter.

Measure your filament diameter along several points and average the result. Use that number in your slicing program. Also, several people have suggested looking at your e steps, I second that! http://calculator.josefprusa.cz can help you figure out your e steps.

It sounds like it’s been a while since you’ve last printed – could your plastic have swelled during this time, increasing its diameter enough that the effective flow rate has been nudged upwards? Although ABS is commonly associated with water absorption, PLA supposedly will absorb water, too.

Looks like your extruder is losing its grip on the filament. Clogged drive wheel?

Thanks everyone for your suggestions. The e-step was to high and it was feeding to much material. I bumped it back down from 1889 to 1420 and the prints are much better. Still pushing a little to much material but the prints are much better now.

@Mark_DeNeve - Excellent. You should try to get the e-steps as close to perfect as possible. Also, be aware of any slipping that may be happening, or perhaps under-powered steppers (adjust the trim-pot) that may be affecting the reading. Doing a test extrusion usually ends up being a different speed than printing extrusion. You want to make sure you extrude consistently at printing speeds. Otherwise the E-steps you get during configuration could be very different.