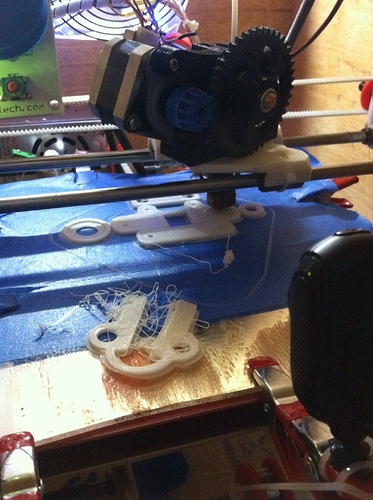

So apparently it’s harder to keep big prints down when printing with PLA and no heated bed in a room with crap temps… I got two good pieces out of it and it started to fail.

/rant/

So the i2 is being temporally put out of commission and is all packed up… Moving in a month maybe ill get a chance to mess with it this summer, this thing is just stressing me out so bad I can’t think about anything else. And out of frustration I’m sure I will keep breaking it even more.

/rant/

I think when I do get to messing with it I’m going to set it up to work with the PI and try my hands at octoprint.

Ill keep that in mind next time I print with PLA. I read that somewhere and completely forgot about it.

Those are ob1.4 idlers, so some of those pieces are a pita to print. Wait till you get to the Y carriage.

Few notes. The extruder bearing clamps have a flat in 2 holes that needs to be carefully dremel’d smooth. And you will need to predril the X motor and idler very carefully. You want it really tight , but removable again. Expect the clamps to do nothing and you should get it right. You probably want to use 10mm screws so you can use screw/lockwasher/washer/nut I ended up using mostly 8 and 10mm. It is rough getting it together but worth them not getting lose. Try printing less pieces at a time. I think you have some extras on the bed .

Ya I have my brim set to 2 and was trying to link the brims to keep the parts flat on the bed… Worked accept that one part I didn’t split it with splicer first. Thanks for the tips on the ob1.4 I’m actually looking forward to building that printer.

I saw the y carriage… Does not fit In my build area as I only have 75% use of my print bed (no frog plate)

The parts on the bed were a y idler a j head adapter, and a Bowden adapter for the j head. And a few other parts.

I’m just taking a break until summer when I have a lot more time and room to mess with it. Right now I’m getting more frustrated with it and most likely causing issues with the printer rather than the printer itself causing issues.

And Adidas I take it you have experience building the ob1.4 or one like it since I see you have a OB of some version so I might hit you il up on some help or tips and tricks when I get around to building mine.

yeah mine is a modified 1.4 longer X and Z

Something I also found with certain brands of blue painters tape - the tape itself should have a matt almost hairy finish. If it’s shiny, use fine sandpaper (eg: 800 grit) to scratch it up slightly. As mentioned elsewhere, avoid getting skin grease on the tape and/or wash the tape with isopropyl alcohol.

@Jeremy_G_WeisTek_Eng is your printer enclosed? I have found, even with a heated bed, if the temperature in the room varies or there is a draft my flat prints will curl up.

Ya mine is included in a monstrosity of a box  it works though i get way less to almost no warping with abs, although I need to fix some stuff with it though.

it works though i get way less to almost no warping with abs, although I need to fix some stuff with it though.

it works though i get way less to almost no warping with abs, although I need to fix some stuff with it though.

it works though i get way less to almost no warping with abs, although I need to fix some stuff with it though.