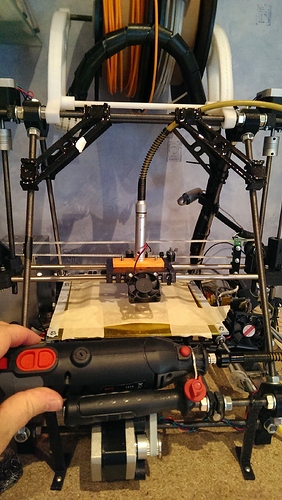

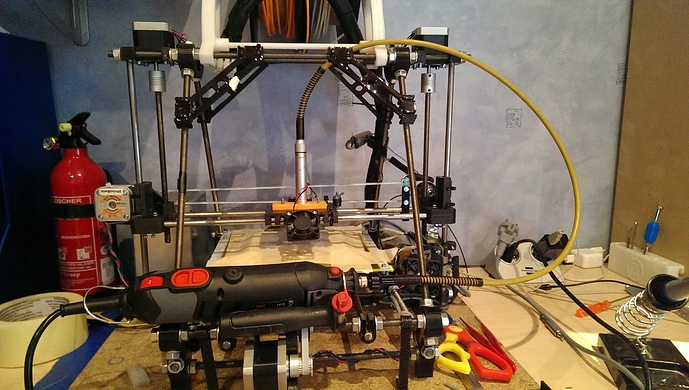

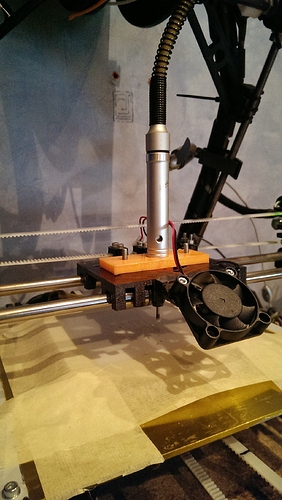

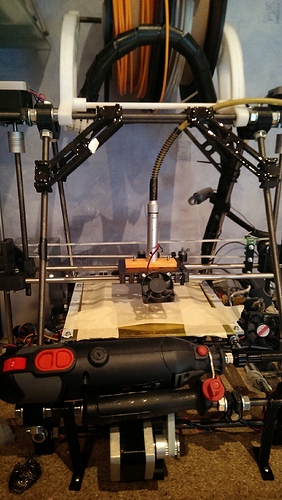

Since I had to disassemble my hotend this weekend (it leaked) I used the chance to try out a dremel shaft mounted on the X-carriage. I tried to mill an elefant into a PLA printed plate. It kind of worked but I need more tries to find the right z-position and mill bit. Did anyone else try to use a reprap for milling ?

I’ve seen people try to mill foam and engrave copper coated boards for PCBs. Mendel style Rep raps arent really suited to the task though (from what I’ve been able to gather) as the design doesn’t consider the lateral and axial forces involved in pushing a milling tool through a workpiece. If you look at even the really cheap cnc mills, they all use ball screws or chain drives to move the head as belts tend to slip of stretch under load. I’m not saying its not worth experimenting with, just that mechanically you’ll likely find the limits pretty quickly and at worse you could damage your bot.

I would think that high strength fishing line might be better than a rubber belt for driving a CNC. Of course, you would have to have more strength in the line than the axial forces you would get. For PCB’s, I think you will be ok with a belt drive, but this is just my 2 cents without experience.

@NathanielStenzel “rubber” belts have steel or glass fibre wires inside, which bear the load.

Anyways, the triangular threaded rod frame is extremely weak, even with the cross supports on it. The minimum you’d want to use for milling would be a MendelMax, preferably a 90 or Prusa 3. Then you’ll need some thicker smooth rods and, for precise milling, wider belts with little backlash.

I built my Mendel90 around the idea of being able to use it for some light milling / routing, but never dared to actually try it out.