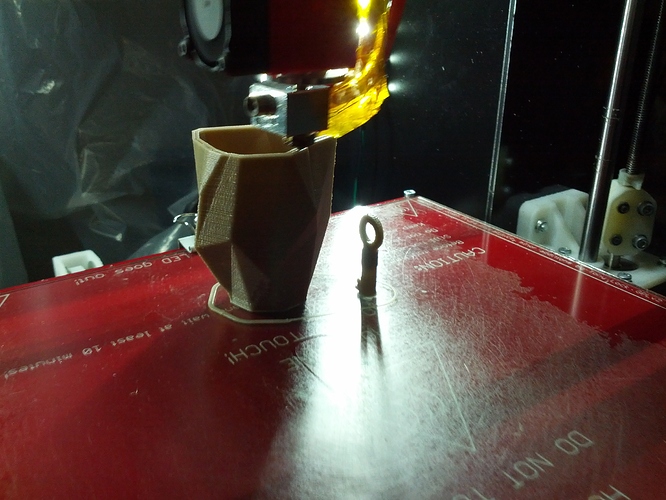

Showing off the E3D nozzle and looking for some advice…

Nylon printing attempt 1:

Set extruder to 245 (247 first layer), bed temp to 125 (130 first layer) and let it rip (all other settings, from ABS, stayed the same.)

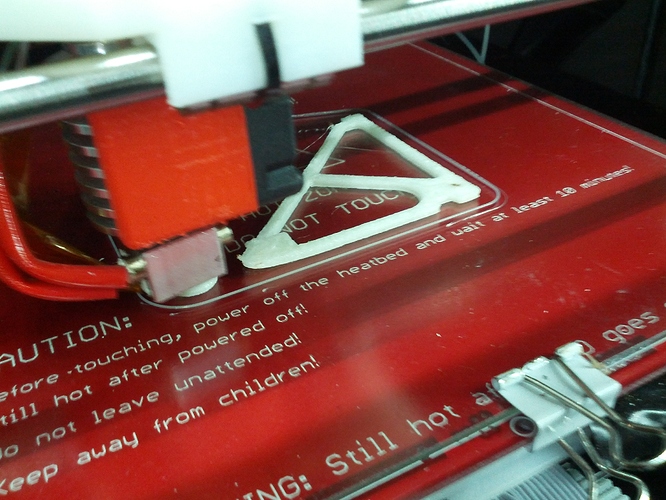

Printing onto a glass bed sprayed with hairspray, I got decent adhesion. The parts stuck for the first 8-12 layers, but then the corner of the triangular framing piece started to peel up. This eventually made the x-axis miss some steps, and I canceled the print to conserve the remaining 3 meter sample of Taulman 316 I have.

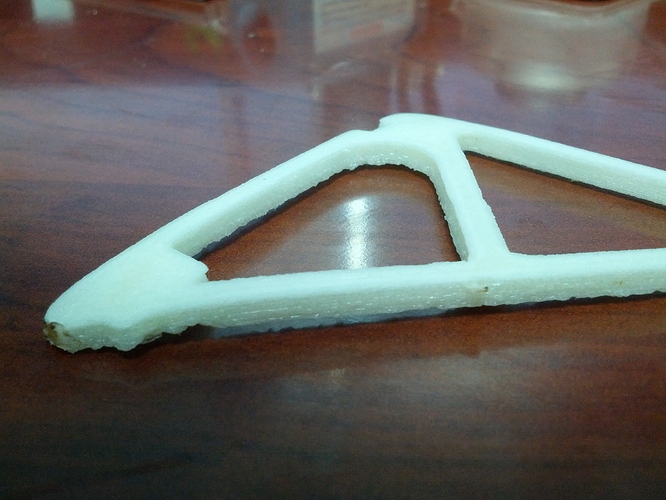

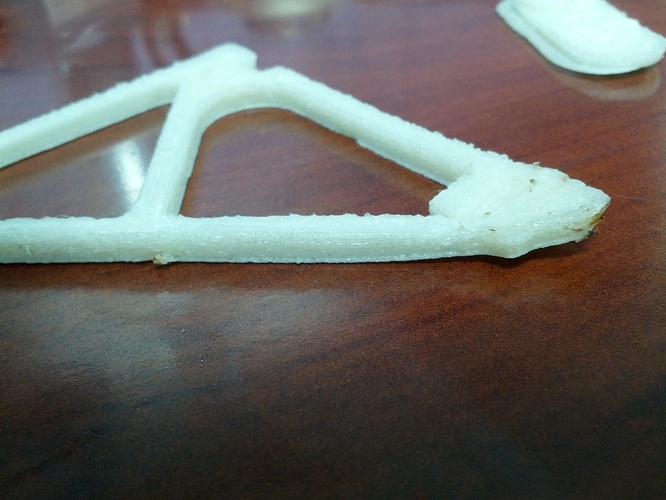

As you can see from the pictures, inter-layer adhesion is good, but the general surfaces produced are a bit sloppy. This might be over-extrusion, but as a lot of crackling and puffs of steam (or smoke?) came from the extruder during the print, I think the filament was fairly moist.

Anyone have any recommendations? Bed temps? I’m teetering on the edge of buying some garolite from McMaster - would 1/8", multipurpose or flame retardent be what I’m after? 8667K213 is the specific part number - although I’ll have to trim it to fit my build platform. Judging on the strength and resilient flexibility of these parts, I’m likely to make a switch to near exclusive nylon prints. With an all SS nozzle and Taulman filament, I have assumed I don’t have any noxious fumes to worry about?