A bit of background: Nominal 220V is European (and other countries) standard where one leg is hot 220V RMS (316V peak) and the other is a neutral leg. Nominal 240V is American (and Canadian, and a few other countries) where both legs are hot and each leg is 120V RMS (172V peak) relative to a neutral (which might not be run to the outlet) but they are in opposed phase, so between them they are 240V RMS (345V peak). Fortunately, nominal 220V ranges between 220V and 240V depending on country, so it’s generally OK to use worldwide “220V” equipment with US 240V power.

This difference between systems means that “L” and “N” are misleading when using equipment marked for nominal 220V on a US 240V system. In Europe, the would be 220V load and neutral, but in the US they are both hot, and there is no distinction between them. I’ve often seen them designated “L1” and “L2”

Fortunately, voltage is only a relative thing, so as long as equipment doesn’t care about a difference between neutral and ground — and most doesn’t — what it sees is 240V RMS between “load” and “neutral” so it doesn’t matter.

A lot of US-centric devices use GND for the supply, but many others differentiate betweeen GND as a DC 0 voltage reference and PE for “Protective Earth” for the ground line in your power cord that is actually connected to earth at your house.

Most 240V outlets have only two hot and one ground. There are a few that have a neutral as well, but that is usually because they are meant to feed something that needs both 240V and 120V supplies, or to feed a sub-panel. Electric range outlets are one example of this; modern US code requires range outlets to be 120V/240V four-prong style and modern ranges may take advantage of both. By contrast, electric dryers and EV chargers typically don’t have a neutral wire at all. Most 240V outlets are three-conductor; L1, L2, and ground.

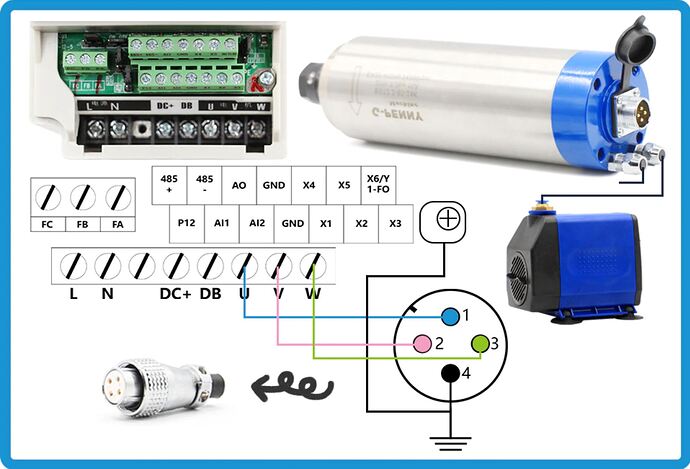

My 240V CNC OX has only two hot and ground. I got a 240V CW-3000 so that I could put it behind my e-stop with the spindle, so that one of the emergencies I could stop with the button would be water spewing from a broken coolant line. If I were using a 120V CW-3000 as a cooler, I would have had to have run a four-conductor supply, and put the cooler on one hot leg and the neutral line. This means that I’m running both hot lines through my e-stop, which is a dual-pole device.

When you wire up 240V, never use an unmarked white wire to carry one of the legs. Unmarked white wire must be neutral, never hot. This is a safety consideration. If you need to run a hot leg across a white wire, both ends must be marked; normally by wrapping a few turns of black electrical tape around them.

Therefore, make sure you mark your white wire, and then your two load wires (typically called “L1” and “L2”) will connect to L and N.

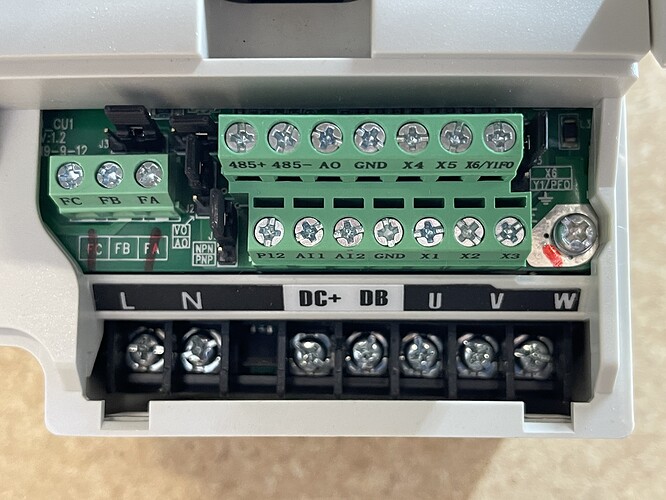

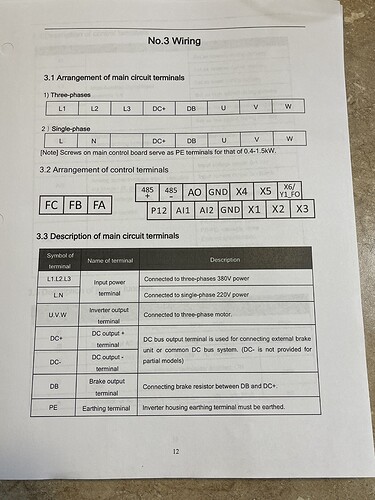

I don’t see a terminal labeled “PE” in your picture, but the big screw on the right side of the circuit board with the red mark next to it looks like it is meant for the PE connection. (I would have expected it to have been a screw terminal on the bottom row but I guess they cheaped out on that.) Don’t just screw a wire into that; use a crimped ring (or spade) terminal. You’ll have two terminals because you’ll also be running a wire to the ground connection on your spindle from the same screw.

Use ferrules for all the other wires that go into both styles of connector otherwise to protect against wires breaking.

If you are trying to wire all the way to the breaker and not just to an existing outlet on the wall, it gets complicated. Gauge of wire depends in part on the length of the run. But it also depends on what outlet you use. I don’t know how much power your pump uses, but 2.2kW is about 10A at 240V, which is much less than any 240V outlet you buy. You must size the breaker to protect the weakest downstream component. So you could put in a 30A outlet and wires that could carry 20A and put a 15A breaker behind it and be safe, but if you put a 50A breaker and wires sufficient for 30A and a 50A receptacle that would be a fire hazard. You will need a dual-pole breaker with the poles tied together. This will use two adjacent spots in your breaker panel.

So just to be clear here, are you planning to run wire through the wall for this on your own?

I don’t normally wire anything up to 220V. I will have a ground, neutral, and two hots right? Where do I lay all of those 4 wires down here? What size wire will I and breaker will I need?

I don’t normally wire anything up to 220V. I will have a ground, neutral, and two hots right? Where do I lay all of those 4 wires down here? What size wire will I and breaker will I need?