Hi, I have a Kurzweil K2000RS sampler from the early 90s. Because of the form factor it can be uncomfortable to program the machine for long periods as the front panel is typically vertical when on a desk or mounted in a rack. Using an angled rack would go a long way to fix this but because of the size and bulk of the machine (very heavy) that can also present challenges.

What I’d like to do is build a desktop remote controller that includes a duplicate of the front panel controls and display.

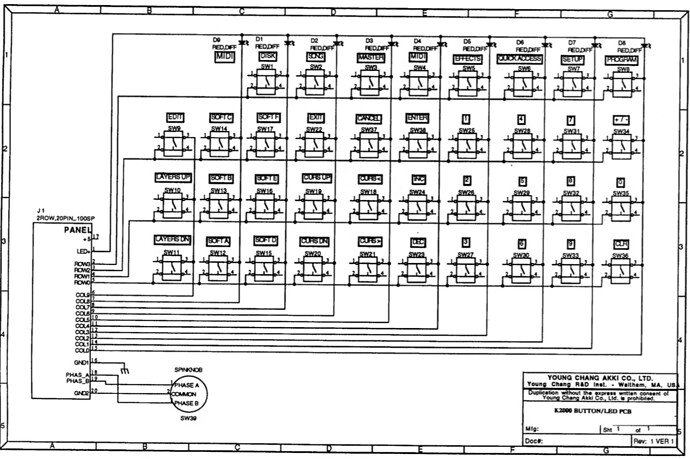

I’ve done a few upgrades to the machine including replacing the LCD Display and installing a SCSI2SD board in place of the original SCSI hard drive. In the process I got to see how things were connected to the display and front panel:

https://helium.deepgreen.ca/dave/K2000R_Display/K2000R_Display_Upgrade.html

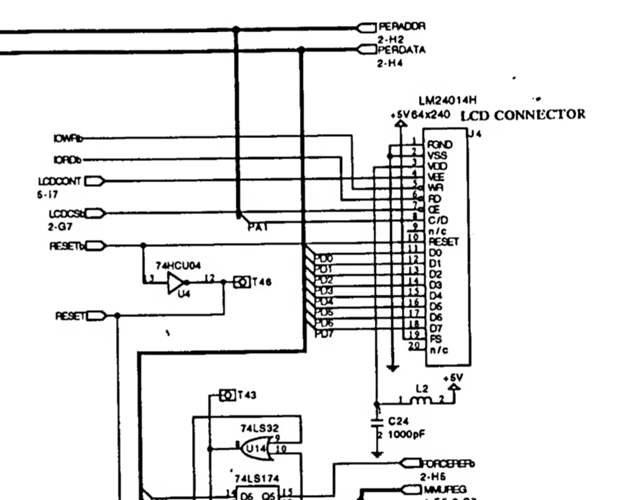

Each component is connect to the main board via a 20 pin ribbon cable. The LCD is a Toshiba T6963 based 240x64 display:

All control and power is delivered over the 20pin ribbon cables.

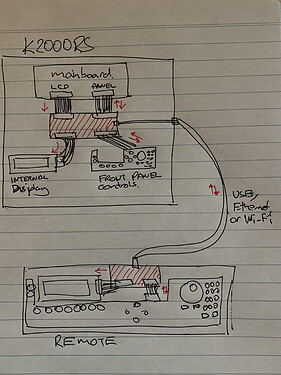

I don’t have an electronics background but have done a bit of coding. The naïve idea I have is to create 2 custom boards (Arduino?) connected via USB, Ethernet or Wireless. One board inside the Kurzweil and the other in the desktop remote enclosure.

The internal board would be inserted internally between the main board and both the display and front panel respectively allowing the signals to pass though directly and also be duplicated and transmitted to the external board so that its display and controls are in sync. For the Desktop Remote I could either buy a keyboard version of the panel board …or create a custom version so I could use my own choice of mechanical switches and encoders etc. I imagine that for the display it would just be relaying the signal one way from the Kurzweil to the desktop remote but the front panel would be 2 way as there are a number of LEDs that change either via direct button presses or software during the synth editing process.

Below is my back-of-the-napkin “design”:

So my question is how feasible is this?