Ah, good catch. I wasn’t thinking of that, just it laying right.

Still waiting for the flat cables.

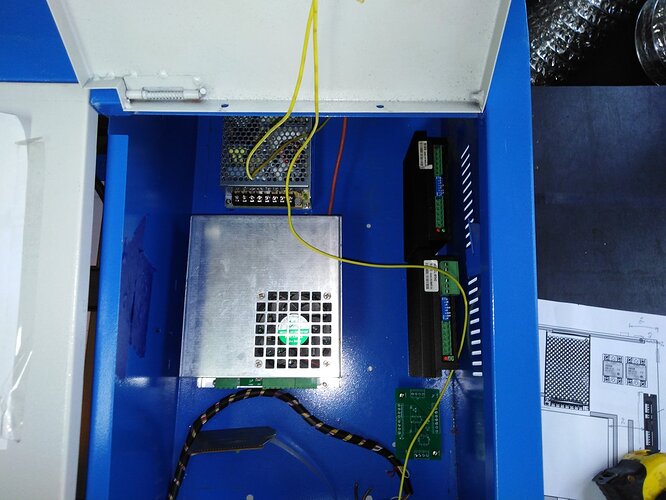

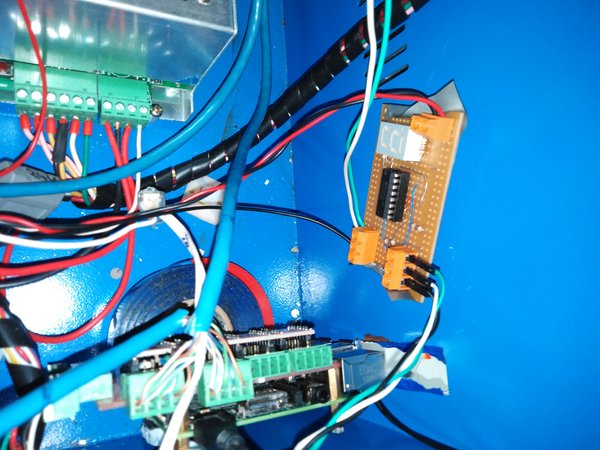

In the meantime, I’ve started planning the layout of the current components in the electronics side of the laser…It’s not pretty at the moment, no excuses except the we’ll get it running then tidy it up properly excuse. When the makerspace originally got the laser, it was set up for operation with an Ardunio via parallel port to a PC that ran Linuxcnc. In installing the Raspberry Pi and the Protoneer CNC hat, some circuitry was added to sort out the voltage levels from the opt-coupler end stops (second photo). THis will be replaced with a PCB we’ve have made. The stepper drivers are standalone DM542s.

I’ve updated to Laserweb4 on the Pi now it’s the hardware’s turn!

FFC cables arrived today.

Still not sure if they shold be A or B style. I’ll find out tonight when I visit Hobart Makers to dismantle the K40 for a rebuild.

EDIT Looks like it’s the A type i.e. not crossed over. So i got the wrong one.  *

*

As of last night, it’s a lot tidier in there. Nothing like a clean slate.

The LPS is being moved 40mm to the left of it’s default position to make room for the two DM542 stepper drives against the right hand wall of the cabinet.

The 24V/5V new supply will sti behind the LPS.

Make sure the LPS has plenty of airflow!

Not trying to derail, just a question: My flat cable just kind of hangs loose in the cutting compartment. Is there a good way to secure it to the wall so that it doesn’t get caught in the laser beam without restricting its ability to move as required?

I have seen these methods:

- These clamp-on opposing edges, stuck to wall: https://amzn.to/2OgL57G

- These in the right width: https://amzn.to/38r80UU. May need to be modified.

- Double back tape to wall.

- A plastic strap double back tape or sheet metal screwed over the cable. I heard you could cut these on a laser cutter if you had one :). Fastening method placed on the outside of the cable area.

Those all seem reasonable. I had previously made a small strap of tape but the adhesive didn’t adhere well in my unheated garage (very cold). Temp and the choice of tape were the issue. I think using the plastic strap and taping/screwing/bolting it down will be my solution. Thanks!

BTW for sheet metal mounting for things that need to come in and out alot (sheet metal strips) I like to use nutserts (rivet nuts).

You can install them from inside or outside the box to hold stuff.

The only problem is getting access with the tool.

rivet nuts: https://amzn.to/3eoFib1

You can put these in by hand or you get to buy a new tool!

I plan to upgrade the fan at the rear of the cabinet. With the extra 24V/5V supply, the load on the LPS should be somewhat reduced which should also help.

I was planning to put the stepper drivers on the right hand side fo the enclosure but this might affect air flow (vents). Plenty of time to change my mind about placement.

I took several of these out during the cleanup. The glue is very strong.

Just know that the most prevalent failure is the HVT and the high power diodes.

I have never seen a LV supply failure.

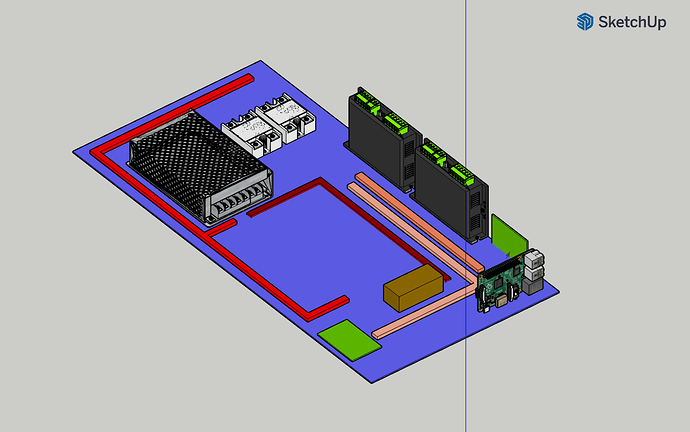

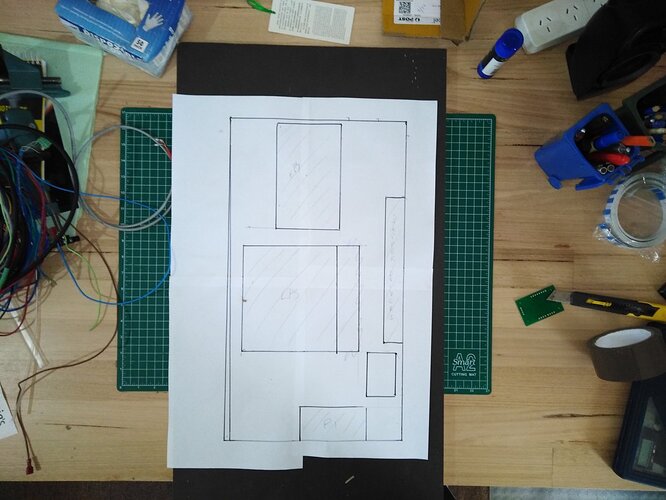

Here’s the planned layout for the K40 update.

The blue are represents the space at the right hand side of the laser cabinet i.e. where the electronics are. The LPS is left off for clarity - it goes in the blank spot in the middle. The red/pink lines are where the wires will run. Red is for mains AC power and is run down the left hand side and around the back so as to separate from any low voltages. The green square is the PCB that handles the opto end stop voltage level change, the brown block is a terminal strip for 24/12/5v from the additional power supply. Two SSRs for air assist and exhaust fan.

There will be 3 IEC connectors on the back panel to provide power for air assist, pump and exhaust. Pump will be permanently powered. Mains power switch will be moved from the front panel to the rear side of the cabinet.

Found a little Oops when I did the cutting and drilling today. Turns out ‘someone’ had the depth of the cabinet at 576mm but it’s actually 500mm. Power supply fits where shown but there’s no room for the fan

Fixable, just means drilling few mores holes and mounting the power supply at 90 degrees to that shown

One solution might be to mount the fan outside the case (still blowing in).

Spoiler: The someone was me

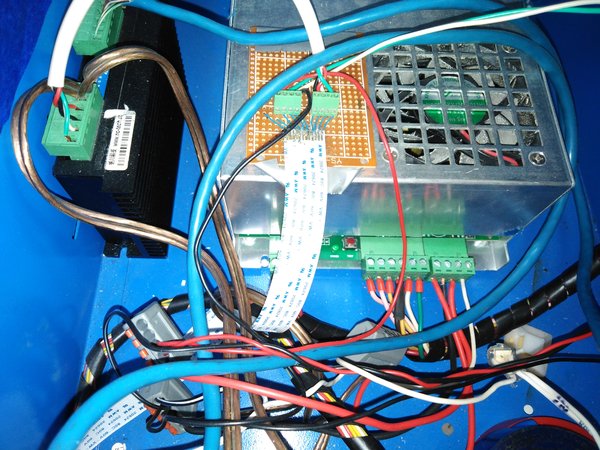

Got chance to do some work on the K40 today. Got the power supplies and stepper drivers mounted. I’ll start making up the wiring loom tonight/tomorrow.

That’s way to neat to work …lol!

Heavy duty (22AWG), 4 core, shielded microphone cable for the stepper motors. A lighter gauge (28AWG) 4 core, audio cable for the control signals from Raspberry Pi to stepper drivers. All DC (5/12/24) power cables are 17AWG, not really necessary but what I had available. Mains wiring to outlets and to power supplies is from standard, 3 core flex.

All stepper driver and Raspberry Pi wires will be terminated with bootlace ferrules, similar to those used to connect the standard laser power supply. Mains wiring will be female spade connectors, these may end up being soldered instead.

Here’s the board I’m building the wiring against in the absence of the laser cutter.

One step forward, two steps back!

The laser tube was replaced about 18 months or so ago and whoever did the install, managed to solder the high tension lead to the tubs. In installing the new power supply and wiring, I’ve been careful to not place too much (mechanical) tension on the high tension lead. Tonight I failed and the glass tube holding the wire, snapped. (Couldn’t find an idiot emoji)

Time to brush up on the specs for a replacement. Any recommended suppliers? I was going to try Cloudray.

Cloudray and Lightobject get consistently good reports here. Here’s a recent conversation on this topic:

While I’m stressing the credit card, is there anything else I should consider replacing at this time? As far as I know, the power supply is OK (the way I’m going though …).

Mirrors and lenses were replaced at the same time as the laser tube (18 -24 months ago)

Looking at this tube replacement.