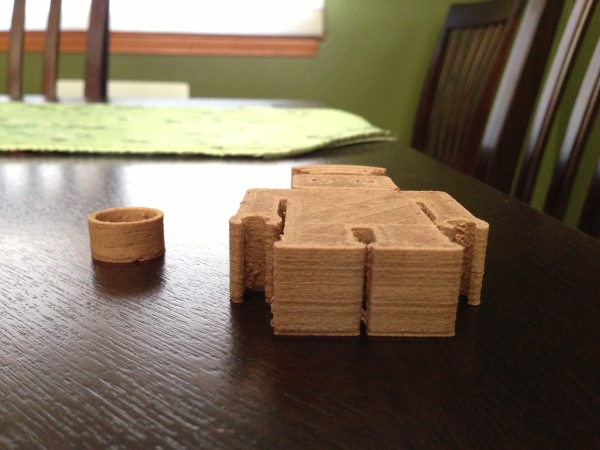

Pretty sure I finally have everything dialed in correctly now! This is an extruded version of my company logo and a small 20mm cylinder that I printed today after fully securing my hot end with a washer. There’s no X or Y wobble. The height was 18.7mm instead of 17.6mm, but that’s easy enough to fix, now that the hard part is done. Feeling really good about these two prints.

A note on the Laywood filament: It oozes like mad at 200C, and you have to print slower or it really gets torn up. The infill for the robot was about 30mm/s instead of 60mm/s. Also, there was a lot of cleaning up that needed to be done. The edges weren’t nearly as clean as the calibration block from the other day. I don’t know if that was speed or temperature.