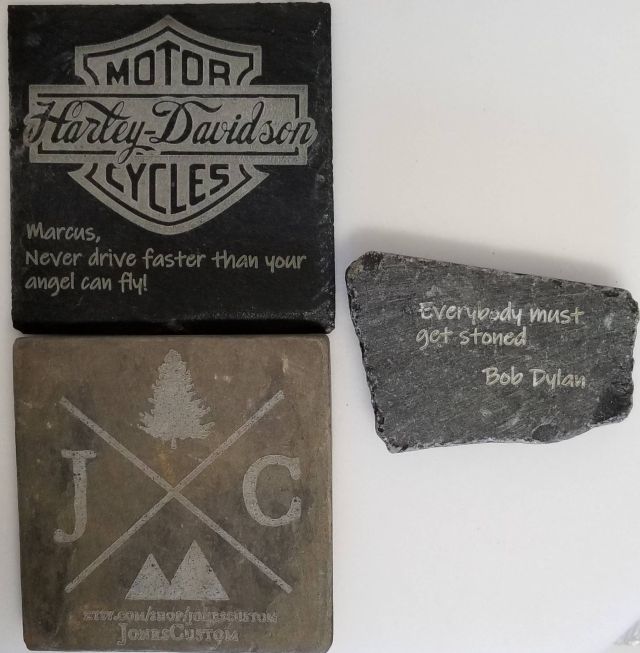

When you laser on most slate and rocks, the etch can be very light looking. Checking out other forums for answers, most agree that pre-coating with varnish or shellac can bring out the contrast. Here is some experiments pre-coating with varnish.

I have been post coating my slate engraving with a clear sealer. Will have to see if there is much of a difference between pre or post coating.

I spray with poly after …

Caution: varnish and shellac do not do well with exposure to water.

What about marine varnish?

Much better but I would sorry about its reaction to standing water like on a coaster.

I would stay with polyurethane…

Typically (as far as I know), marine varnish is spar varnish, and it’s called that because it’s more flexible (I think by including some non-drying oil) so it’s less likely to crack as the spar it is on flexes.

I second @donkjr’s suggestion that PU is probably a better choice generally.

I’ll augment that by saying that if substantial UV exposure is a consideration, an oil varnish (with 2 or more weeks of cure time) is probably worth exploring. The word “varnish” is used to describe a pretty large gamut of finishes based on dissolved resins, drying oils, or a combination of the two, with various additives including non-drying oils (such as in spar varnish), suspended solids (e.g. to modify the surface texture), and now an amazing variety of synthetic compounds—including polyurethane. Drying oils cure under exposure to oxygen and once fully cured are generally less susceptible to water than many of the dissolved resins varnishes. They cure slowly, and the rate of cure depends on oxygen, humidity, and temperature.

A decent (IMO) summary of differences is at