TL;DR: thingiverse gitlab; depends on threadlib, which comes with installation instructions for several prerequisite packages.

The machinist vise on the mill is a beautiful thing, but when I need to change a setup it takes forever to move the jaw by spinning the hex in my hand, and of course putting the handle on would be even slower. The solution is a speed handle, but they are ridiculously expensive. And it happens that I need 5/8" not 3/4" and I don’t want the three-armed version I found.

I found a version on thingiverse, but it’s for 3/4" hex drive, and it was modeled in solidworks. I want a parametric design to not only support 5/8" hex, but also able to support whatever size you need, preferably modeled in OpenSCAD. I couldn’t find it anywhere.

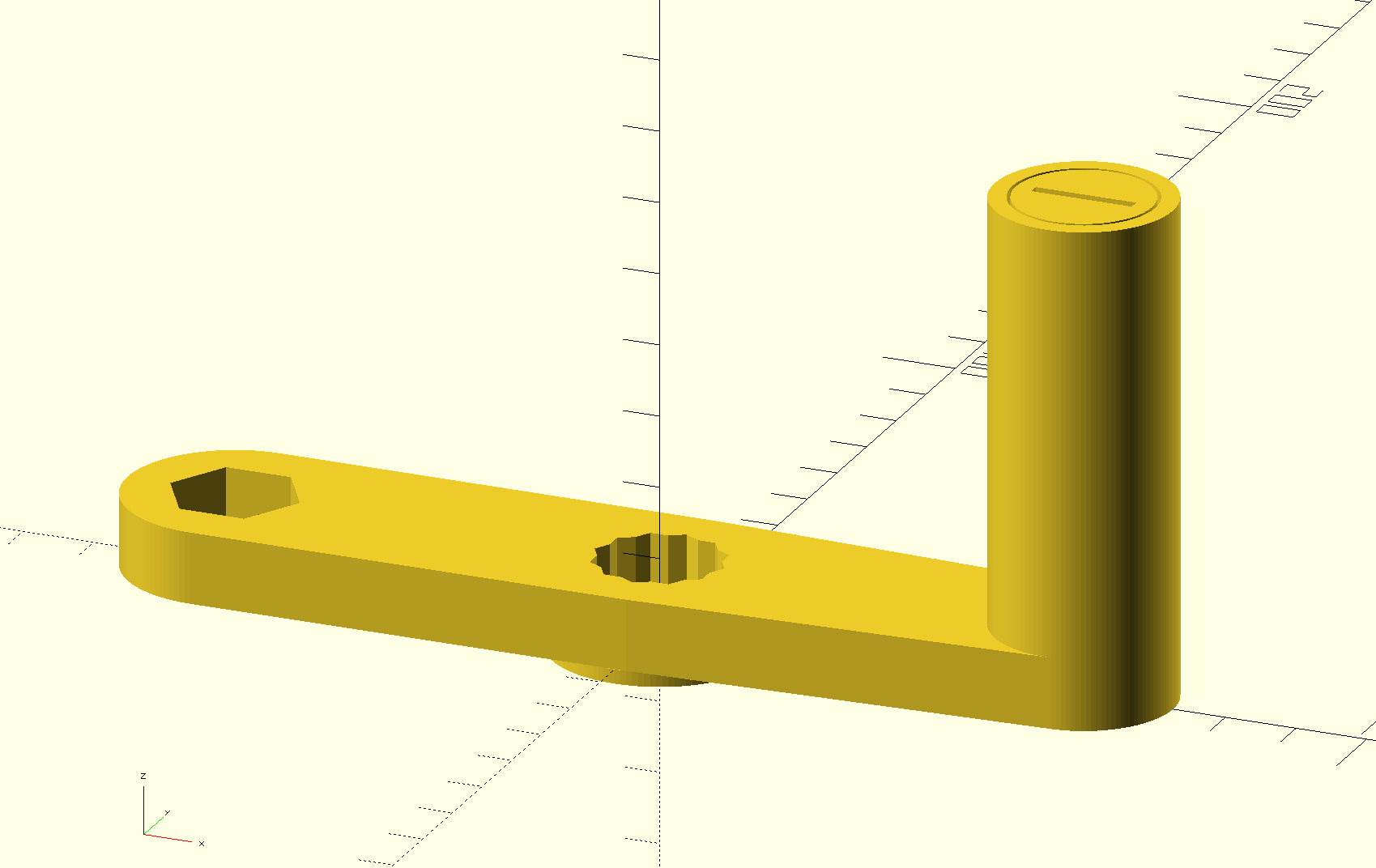

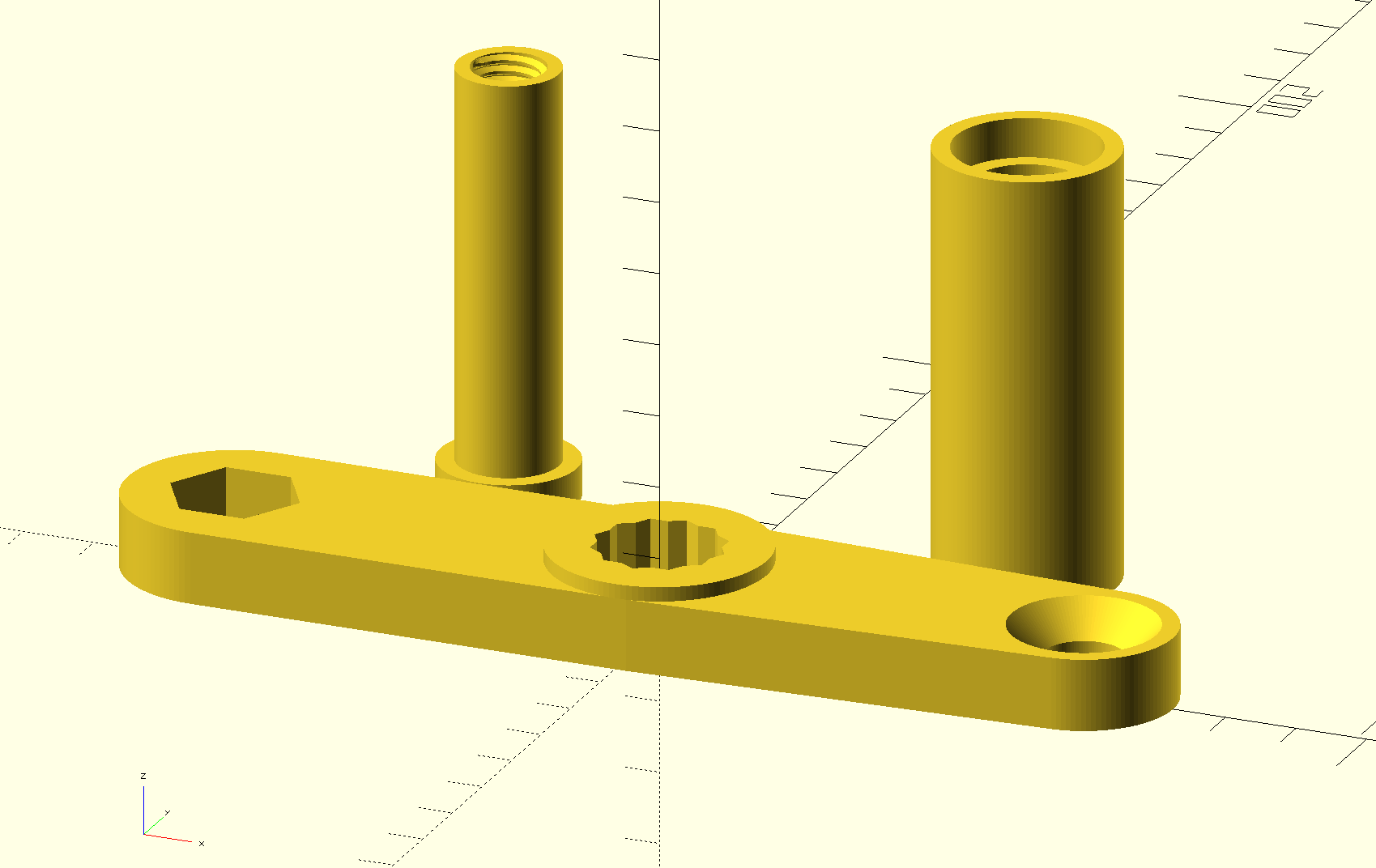

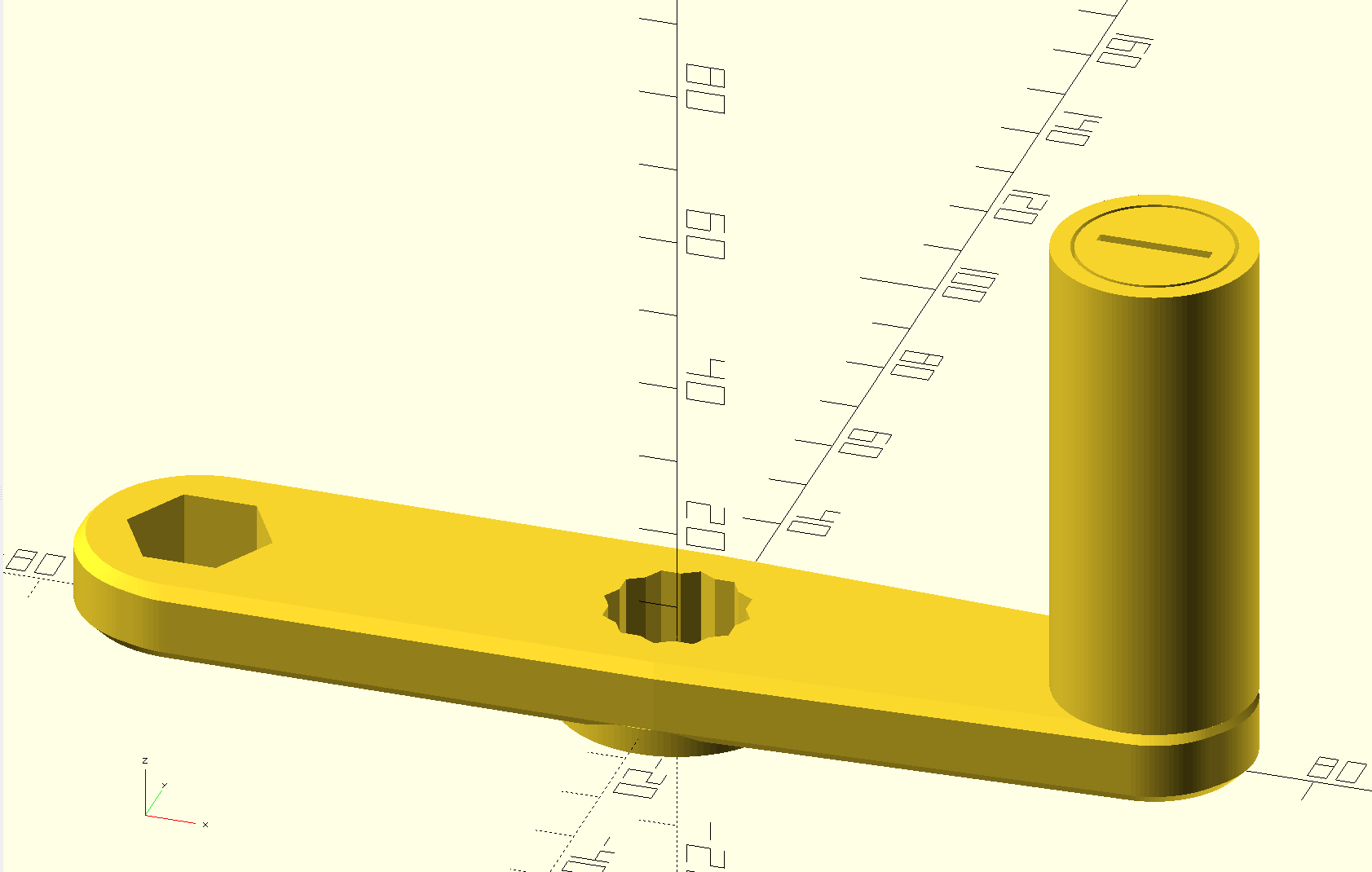

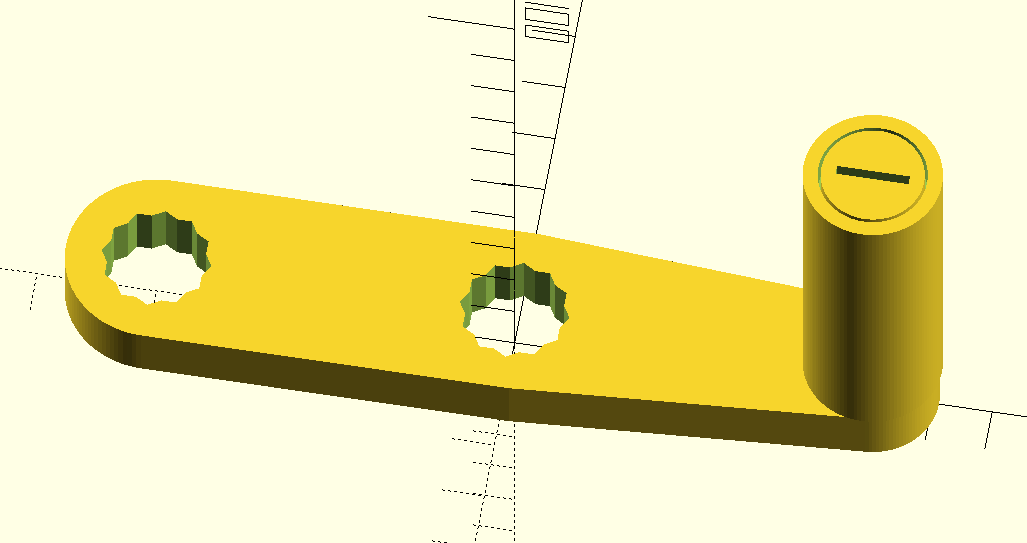

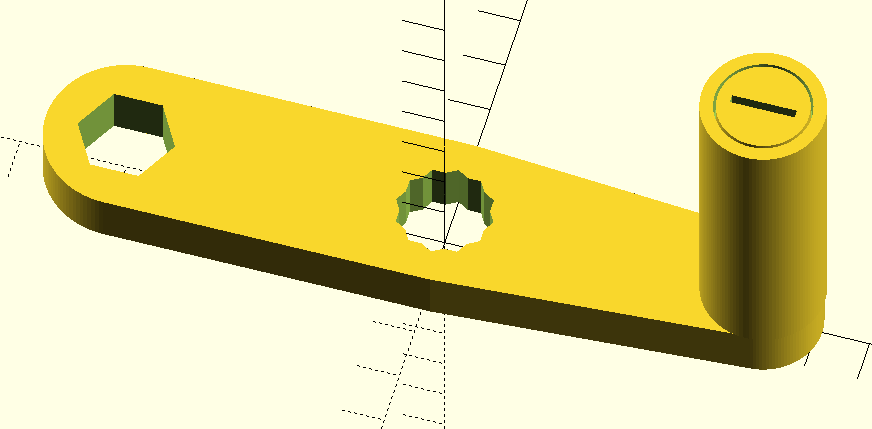

So I modeled it. It allows you to choose the size socket, whether to use a six-point or twelve-point socket, the length between sockets, what thread spec to use for attaching the handle to the crank, how much plastic to put around the sockets, how many thread turns used to attach the handle to the crank (and thus how thick the crank is), how long to make the handle, how thick to make the handle, and how much margin to leave between the handle and the shoulder bolt so that the handle spins freely on the shoulder bolt:

socket_size= 5/8 * 25.4; // 5/8" — 0.625 * 25.4 = 15.875

base=60; // lengths between centers of holes (sockets and handle)

margin=6; // thickness of handle outside sockets and handle nut

thread="M10"; // thread spec, M10 is coarse thread M10x1.5

turns=6; // thread turns; thickness will be turns + 1 * pitch of thread

twelve=true; // false for six-point sockets, true for twelve-point sockets

handle_length=70; // total including depth of crank

handle_margin=0.5; // space between bolt and handle

handle_thick=5; // thickness of shell of handle and of bolt head

I put up files on:

- thingiverse where I may remember to upload substantial changes

- gitlab where I’ll push every change I make

I ended up cleaning up the threads on the bolt and crank with a tap and die. If you have tuned your printer well you might not need to do that.

I’m open to suggestions for improvement!

So I have added a hole inside the threaded portion of the shoulder bolt into which to screw a real metal screw to add strength.

So I have added a hole inside the threaded portion of the shoulder bolt into which to screw a real metal screw to add strength.