Originally shared by John Schneider

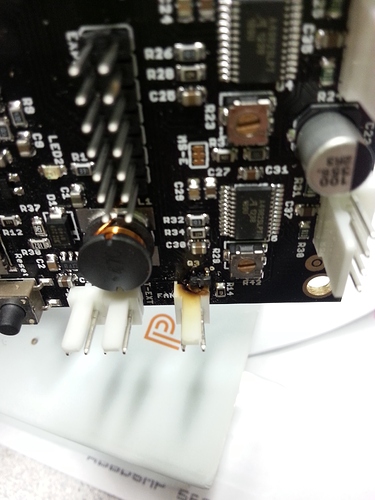

I’m about ready to throw this stupid thing out the window. @PrinterBot1 Jr. Stopped, saw smoke, quickly unplugged it and after ripping it apart, something near the fan pins burned up. I swear, between this and the filament jamming issues, I’m about ready to just set the damn thing on fire.

I am not a PrinterBot expert but that looks as a short circuited surface mounted capacitor (over voltage), or over current on the connector.

Note to self. Will not buy this printer.

That sucks! It sure seems like a hit and miss machine. That is definitely the fan MOSFET though so what did you have hooked to that pin? I’ve run maybe 6 pounds of filament through the Jr in the last 2 weeks (http://hardwired.cc/?p=393) alone.

I had a fan hooked up to it. It seems like with this machine that as soon as it looks like I’ll be able to print for awhile without issue, then something goes wrong. I’ve decided to stop throwing money at it, as it seems like that’s all I do with it. (upgraded belts, pulleys, motors, added a fan, upgraded the extruder).

The fan output was meant for very low currents only.

btw, don’t trust the cheap fans that say 12v/100 mA, measure it; I’ve seen some of them easting much more, and worse, with it’s mouth open…

@Jeff_Karpinski It’s not a good design with the 1.75 Ubis hotend that came with the printer. I’ve had to take a drill to it as well, since the hobbed bolt won’t line up properly. You’re right, the belts and pulleys perhaps weren’t necessary, but the motor for the X axis was, there’s no way that motor should’ve been as noisy as it was. As for the fan, you’re right, that’s my fault for assuming that a fan is a fan is a fan. When it would work, I’d get really good prints.

Yeah its an odd one… folks have had no issues at all with it while others, myself included, had some growing pains. I don’t think its the 1.75mm filament so much but the new hotend is suspicious and the extruder appears much more compatible with 3mm filament out of the box. @Jeff_Karpinski probably also received the non-MakerBot motors so that’s a huge bonus as otherwise the pulleys wobble on the smaller motor shafts. As to the fan, I would argue using an undersized mosfet to save a few pennies is bad on the board designer not the user. @John_Schneider can still save it, assuming Brook doesnt offer to replace your board. Wire up a standard mosfet (irl540 or similar) to one of the unused pins on the board and update the firmware to match the new pin - its not really the end of the world. And honestly, you are just as likely to have these very same issues with any printer unless its preassembled (and even then…).

@John_Schneider Yeah in one of your posts above I hear me 12 hours before pulling this off for a first print, https://plus.google.com/u/0/115793701493192683179/posts/WcGHJCr3qg4

My point is when you are thinking about the money , you should probably take a few hour / half day break. Everything I broke I did so while letting the repeated failures get to me. I would find a problem and have to disassemble the last days work to get to it and because I was frustrated half the stuff that got taken back off would then have issues. Stick with it man, but take breaks when you get frustrated, it only makes everything worse. I think everyone goes threw this, even with replicator2 (etc all),

I’m sure there are a bunch of us who can help you repair that board if its something you can’t fix or have replaced. If you get stuck just ask. That is really easy to fix with the right tools. The parts should be cheap.

I’m going threw almost the same issue with my Prusa Mendel i2 no burnt boards just bad warping and hobbed bolt issues.

I found out though that the ambient temp in the room the printer is in, is to low and is effecting the print quality (causing warping and de lamination of layers.) soon came to the conclusion that an enclosure would solve this issue.

Keep with it. Take breaks and don’t throw the machine it only breaks it more…

Yeah, I have no idea how to go about repairing it. No idea how to change stuff in the firmware to make it work.

If your good with a solder gun you can replace the part that blew. I don’t know what part it is that need to be replaced as I have never used that board. I’m sure someone on here can tell you what part it is.

Depending on the firmware there should be an option for fan enable, setting it to true/false or 0/1 will disable and enable it. You can also disable the fan in slic3r.

Where are you located John? There are roughly 25k people in this particular community. One of us should be close enough to save you shipping. Im around chicago. You should inspect the board closely. Make sure none of the pcb traces fried. Ideally just the mosfet smoked and before the traces vaporized due to excessive current. As long as that is the case it should just be amatter of swapping the mosfet. The jack should be fine as it is.