One of the interesting things about SLA is that there is a large industry of resin techniques and additives for polyurethane, epoxy, and polyester casting resins which may also be applicable the acrylic resins used for 3D printing. I can get pigments and various additives at retail at TAP Plastics, and there are similar stores in most cities.

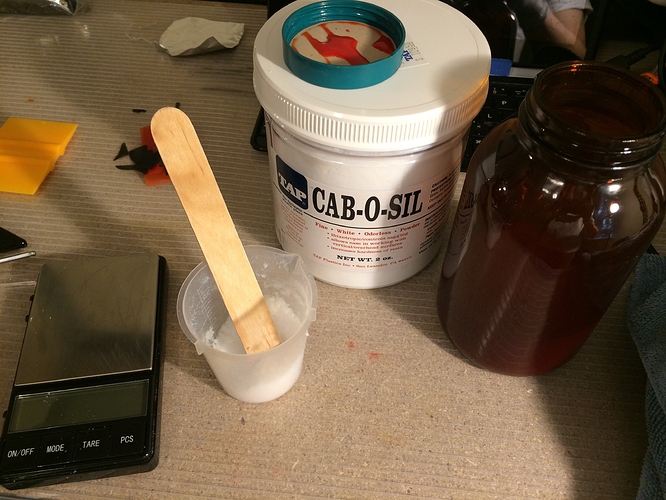

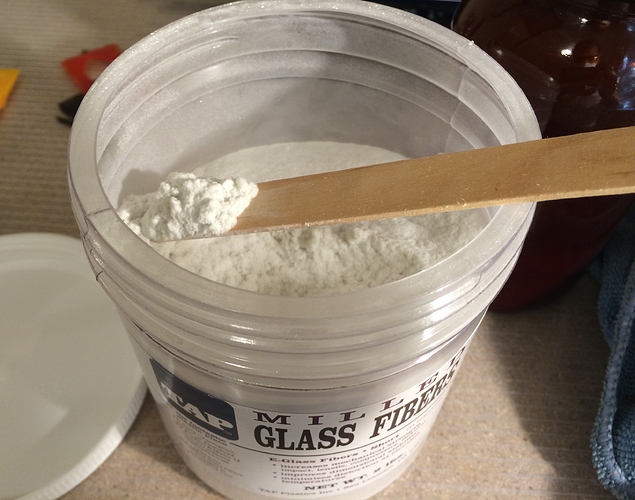

The FunToDo Standard Blend resin is fairly soft (Shore D 30) and presented a better medium for experimentation with strengthening and hardening fillers than the MakerJuice G+ (which is very hard and I would have to test more around changes to its impact resistance given that I have no testing tools). I added 5% (by weight) of milled glass to try to increase strength and then 1% (by weight) of cabosil to make the resin more thixotropic to reduce settling since the milled glass is fairly heavy.

Cabosil could probably be used on its own to increase thixotropy when using powdered pigments in low viscosity resins, although TAP plastics pigment and FTD resins together settle very little even with no additives.

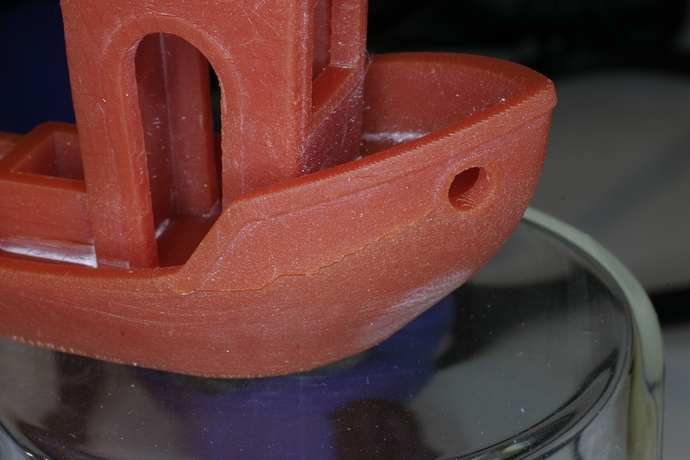

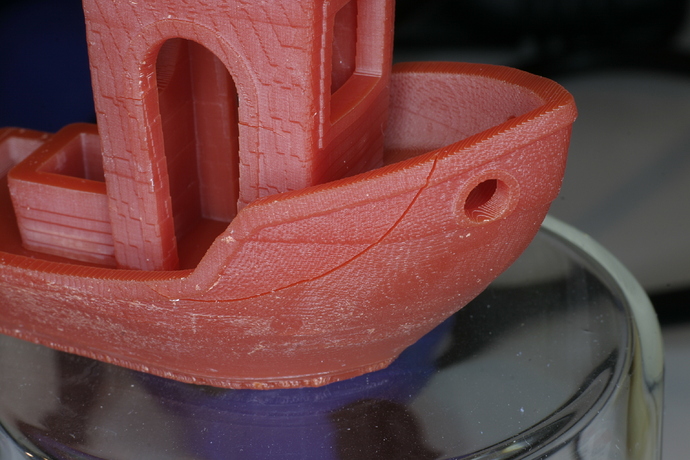

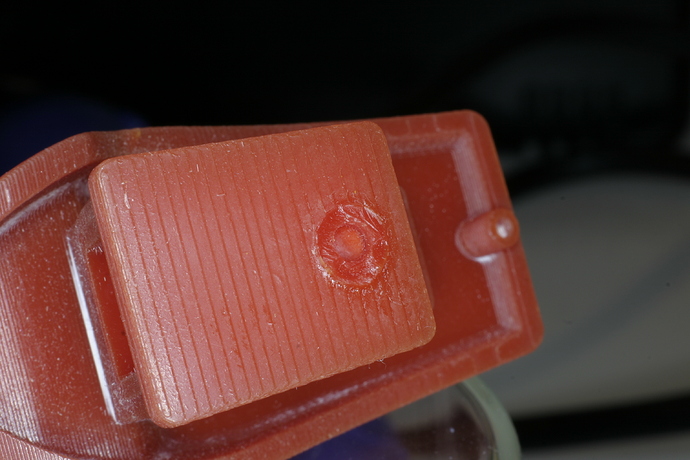

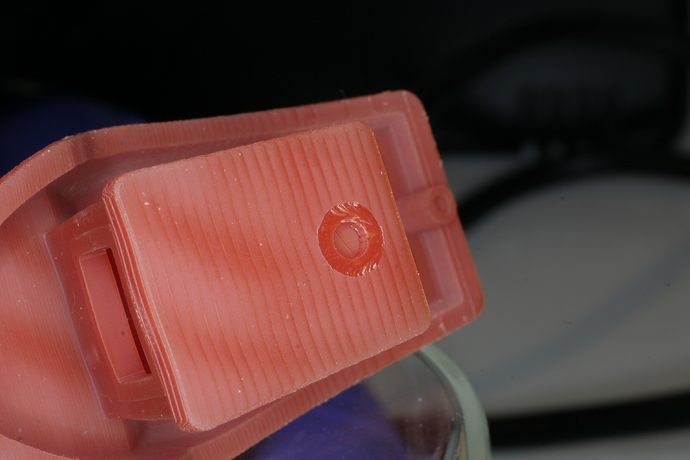

The additives definitely changed the physical properties of the resin, which I tested by bending the bow of 3DBenchy and ripping the smokestack off. The pictures are labelled and depict the differences between the resins. The net is that these additives have their expected effect for 3D printing resins and can be put to some interesting uses.