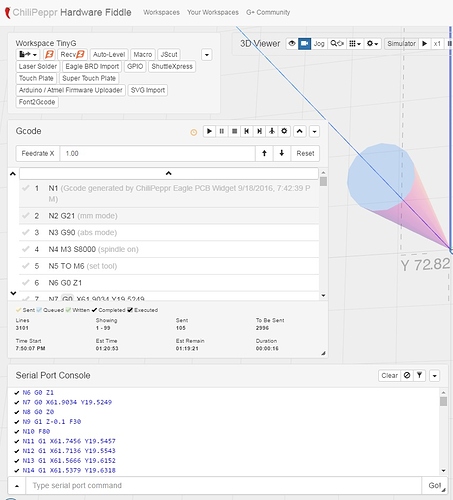

Ok, I’m really confused now. Eagle BRD import turns my CNC into a tool murderer. I load ChiliPeppr. I open Eagle BRD import. I drag in my brd file. Set inflate, spindle speed, etc, render, Gcode. When I hit the Play button on the Gcode, nothing happens, not even M6 dialog popup. I click pause, nothing. I click pause again, the CNC starts running but without turning on the spindle!!! I darn near snapped off my brand new $20 PCB endmill. Fortunately I hit stop real fast and it scraped a tiny scratch into the PCB with the stationary tool without snapping it. Below you see the Gcode has an M3 and an M6. But in the serial console, you see it just started on Line 6 with G0 Z1, it skipped over M3 and M6. So far this only seems to happen with Eagle BRD import because I ran another file I had and also the default logo file and they work fine.

Am I crazy or doing something wrong. I seem to run into a whole lot of problems every time I try to use Eagle BRD import.

TinyG v8 firmware 440.20

SPJS 1.92

Chrome v.53.0.2785.116 m

If you run an air job on the eagle brd generated gcode, does it do this every time? Not sure what the deal is but it does look like your tool is TO not T0 from that screenshot, so I wonder if that’s throwing something off.

You nailed it. Happens every time for me when I run air jobs. I copied the Gcode from Eagle BRD to notepad, changed TO to T0 (with a zero), then pasted the updated Gcode back into ChiliPeppr. That ran fine. I got the tool change dialog and the spindle started up after I unpaused it as expected.

This means there’s a bug in Eagle BRD right? Can it be fixed?

Ok, bug fixed and published. That bug has been in there since the beginning but i’ve run hundreds of jobs, so not really sure. I wonder if some versions of firmware ignore TO vs T0.

Thank you! I ran it again tonight and it works fine now.