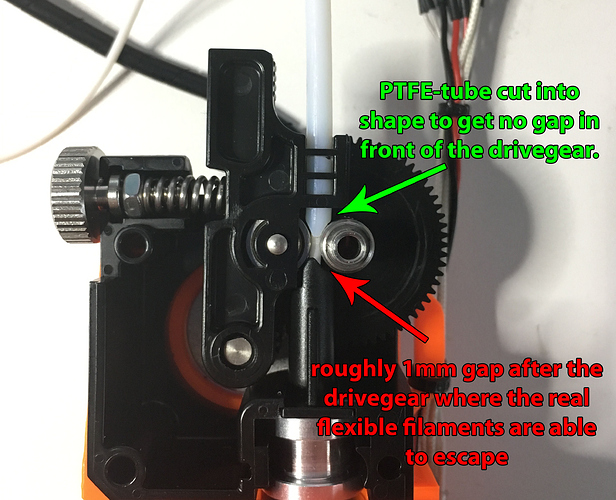

Ok, I am fiddling around with the real flexible filaments and the E3D-Titan. Something like ninjaflex or filaflex. I am able to get a decent amount of prints done. But every now and then, the filament escapes right after the drivegear. Does anyone has an idea or fix for this?

Please stop comments a la “buy extruder XY instead” or “I never have this problem with my XY-extruder”. This is not helping. I have the Titan one here and I just want to fix it.

Flexible filament are a pain to use in a Bowden extruder.

it is a direct-extruder setup.

Am I the only one that try search “XY-extruder” in google?

@Rene_Jurack

It looks like the guide tube under the drive gear is misaligned .You can try to bend it or use a shim to align it

Or try printing another guide tube that lowers the gap to the drive gear.

The only way we got the GregsWade to work with flexibles was to have the PTFE tube wrap around the hobbed bolt (with a notch for the hobb to engage). That and really slow printing solved it. Not sure if you can do that with the Titan.

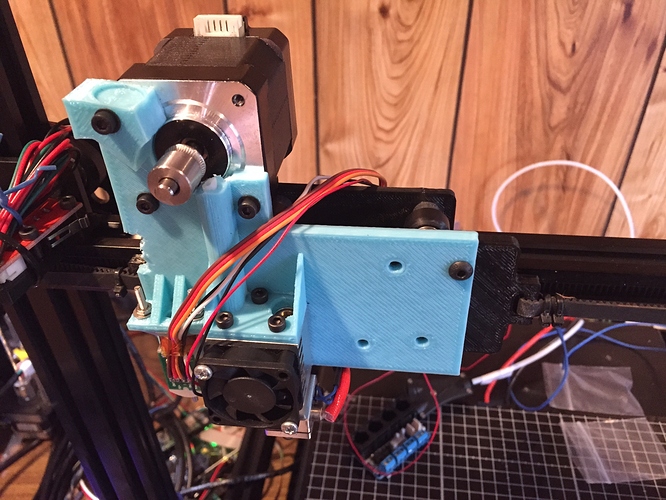

What print speed are you using? I have my profile for flex at halve the speed for lets say pla. Also titan extruder (on a bigbox).

and why you dont try to desing a new conduct closer to the drivegear @Rene_Jurack , maybe that’s an easy solution

it’s kind of a bad picture but i got another filament guide from a friend who uses the 3mm version and didn’t need his 1.75mm guide - and i drilled it to the top and just added to the length with some ptfe (i glued it inside so it does not move on retractions, etc. )

used it for a while without any problems, have been printing some ninja flex lately though without this mod and with better results - just lowered my speed a little, i think it mainly happens when the extruder is pushing filament too fast for too long a time.

how fast are you printing your ninja/fila-flex?

Had the same issues with titan, reduce speed and retraction and it will work.

Yeah, I am down to 20mm/s and things start to work. But I am going to do it like @Tom_Keidar , because I want to print a little faster. Still don"t know why there is such a big gap right from factory.

@Jan_erik_Halvorsen It only looks like misaligned, because the drive gear sits a bit crooked without the lid in place.

Probably worth making a new guide tube. Mine’s not like that though I do find it to be a bad fit for 2.85 filament. I don’t think it’s as refined of a design as they do.

Their pictures are bad but based on the text, I think you’re supposed to do similar to what +Tom Keidar shows above.

I wrote up my findings a while back when printing with TPU. TLDR lessen the tension and reduce speed a touch. http://print.theporto.com/posts/printing-ninjaflex-tpu-filament-on-the-e3d-titan-extruder/

Thanks! Overtime, I run into an issue or figure something out, I write it up on the blog. It’s hard to remember everything.