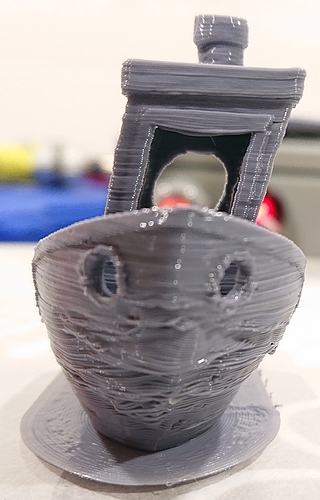

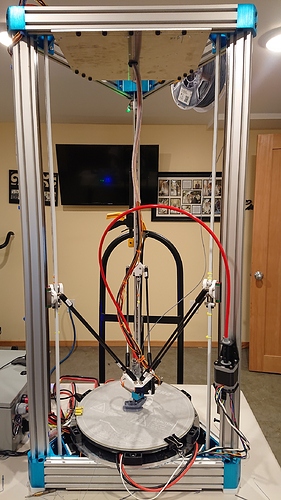

This is my first time building up a 3D printer, and I am running into issues. I now have 8 Benchie3D’s that all have tilt, to the same degree and I cant seem to find the root cause.

I have tried:

- Rotating the effector

- Changing around my endstops to try and make things worse/better

- Adjusting my arm_radius (was 178.54, now is 183.5)

- Tightening the belts

- Running a full tune

- Running with no tuning (remove config-override delta.grid, then resting)

- Printing through OctoPrint, Printing local SD card (print foo.gcode)

- Making sure my machine is square

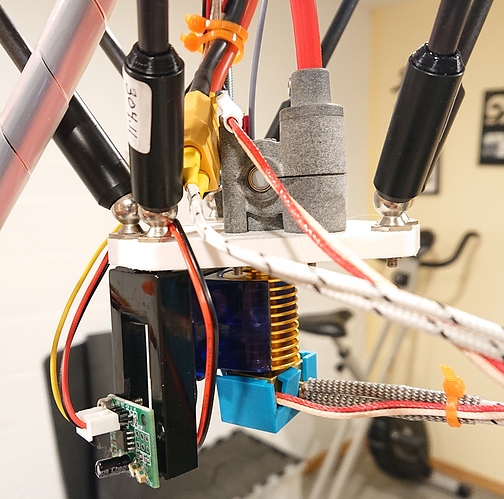

My controller is a bit different than most. I am running an SDK V1.3 board with uStepperS drivers in a closed loop configuration.

I am honestly kinda stumped. I cant seem to find anything that effects the tilt, for better or worse. Any ideas???

More info that I hope can help:

(My calibration sequence)

G32 G28 (Full calibration, then return to home)

(Manually: jog down to touch the plate)

M306 Z0 (Set Z to 0)

G28 (Go home)

M500 (Save it)

reset

G31 (Full bed leveling)

M374 (Save bed leveling)

resetSend: version

Recv: Build version: edge-6a09a62, Build date: May 6 2019 12:53:34, MCU: LPC1768, System Clock: 100MHz

Recv: 5 axisroot@octopi:~# cat config.txt

# Smoothieboard configuration file, see http://smoothieware.org/configuring-smoothie

# NOTE Lines must not exceed 132 characters, and '#' characters mean what follows is ignored

## Robot module configurations : general handling of movement G-codes and slicing into moves

# Basic motion configuration

default_feed_rate 8000 # Default speed (mm/minute) for G1/G2/G3 moves

default_seek_rate 8000 # Default speed (mm/minute) for G0 moves

mm_per_arc_segment 0.0 # Fixed length for line segments that divide arcs, 0 to disable

#mm_per_line_segment 5 # Cut lines into segments this size

mm_max_arc_error 0.01 # The maximum error for line segments that divide arcs 0 to disable

# note it is invalid for both the above be 0

# if both are used, will use largest segment length based on radius

delta_segments_per_second 100 # For deltas only, number of segments per second, set to 0 to disable

# and use mm_per_line_segment

# Arm solution configuration : Cartesian robot. Translates mm positions into stepper positions

# See http://smoothieware.org/stepper-motors

#alpha_steps_per_mm 76.26 # Steps per mm for alpha ( X ) stepper and tower @1/12

#beta_steps_per_mm 76.26 # Steps per mm for beta ( Y ) stepper and tower @1/12

#gamma_steps_per_mm 76.26 # Steps per mm for gamma ( Z ) stepper and tower @1/12

alpha_steps_per_mm 150 # Steps per mm for alpha ( X ) stepper and tower

beta_steps_per_mm 150 # Steps per mm for beta ( Y ) stepper and tower

gamma_steps_per_mm 150 # Steps per mm for gamma ( Z ) stepper and tower

# Delta configuration

# See http://smoothieware.org/delta

arm_solution linear_delta # Selects the linear delta arm solution

#arm_length 250.0 # This is the length of an arm from hinge to hinge

#arm_radius 124.0 # This is the horizontal distance from hinge to hinge when the effector is centered

arm_length 304.11 # this is the length of an arm from hinge to hinge

#arm_radius 178.54 # this is the horizontal distance from hinge to hinge (CAD value)

arm_radius 183.5 # this is the horizontal distance from hinge to hinge (Guessing with grid numbers)

# Planner module configuration : Look-ahead and acceleration configuration

# See http://smoothieware.org/motion-control

acceleration 3000 # Acceleration in mm/second/second.

#z_acceleration 500 # Acceleration for Z only moves in mm/s^2, 0 uses acceleration which is the default. DO NOT SET ON A DELTA

#junction_deviation 0.05 # See http://smoothieware.org/motion-control#junction-deviation

junction_deviation 0.001 # See http://smoothieware.org/motion-control#junction-deviation, updated as per the Nimble documentation

#z_junction_deviation 0.0 # For Z only moves, -1 uses junction_deviation, zero disables junction_deviation on z moves DO NOT SET ON A DELTA

# Cartesian axis speed limits

x_axis_max_speed 21000 # Maximum speed in mm/min

y_axis_max_speed 21000 # Maximum speed in mm/min

z_axis_max_speed 21000 # Maximum speed in mm/min

# Stepper module configuration

# Pins are defined as ports, and pin numbers, appending "!" to the number will invert a pin

# See http://smoothieware.org/pin-configuration and http://smoothieware.org/pinout

alpha_step_pin 2.2 # Pin for alpha stepper step signal

alpha_dir_pin 2.6 # Pin for alpha stepper direction, add '!' to reverse direction

alpha_en_pin 2.1 # Pin for alpha enable pin

alpha_current 1.5 # M1 stepper motor current

alpha_max_rate 24500 # Maximum rate in mm/min

beta_step_pin 0.19 # Pin for beta stepper step signal

beta_dir_pin 0.20 # Pin for beta stepper direction, add '!' to reverse direction

beta_en_pin 2.8 # Pin for beta enable

beta_current 1.5 # M2 stepper motor current

beta_max_rate 24500 # Maxmimum rate in mm/min

gamma_step_pin 0.22 # Pin for gamma stepper step signal

gamma_dir_pin 2.11 # Pin for gamma stepper direction, add '!' to reverse direction

gamma_en_pin 0.21 # Pin for gamma enable

gamma_current 1.5 # M3 stepper motor current

gamma_max_rate 24500 # Maximum rate in mm/min

## Extruder module configuration

# See http://smoothieware.org/extruder

extruder.hotend.enable true # Whether to activate the extruder module at all. All configuration is ignored if false

#extruder.hotend.steps_per_mm 130 # Steps per mm for extruder stepper

extruder.hotend.steps_per_mm 2630 # Steps per mm for extruder stepper, updated for nimble, 30:1 gear, 1/16 micro stepping, GOLD, tested on 100CM

extruder.hotend.default_feed_rate 600 # Default rate ( mm/minute ) for moves where only the extruder moves

extruder.hotend.acceleration 120 # Acceleration for the stepper motor mm/sec²

extruder.hotend.max_speed 150 # Maximum speed in mm/s

extruder.hotend.step_pin 2.13 # Pin for extruder step signal

extruder.hotend.dir_pin 0.11! # Pin for extruder dir signal ( add '!' to reverse direction )

extruder.hotend.en_pin 2.12 # Pin for extruder enable signal

# Extruder offset

#extruder.hotend.x_offset 0 # X offset from origin in mm

#extruder.hotend.y_offset 0 # Y offset from origin in mm

#extruder.hotend.z_offset 0 # Z offset from origin in mm

# Firmware retract settings when using G10/G11, these are the defaults if not defined, must be defined for each extruder if not using the defaults

extruder.hotend.retract_length 0.8 # Retract length in mm, as per the E3D V6 wiki, for PLA

#extruder.hotend.retract_feedrate 45 # Retract feedrate in mm/sec

#extruder.hotend.retract_recover_length 0 # Additional length for recover

#extruder.hotend.retract_recover_feedrate 8 # Recover feedrate in mm/sec (should be less than retract feedrate)

#extruder.hotend.retract_zlift_length 0 # Z-lift on retract in mm, 0 disables

#extruder.hotend.retract_zlift_feedrate 6000 # Z-lift feedrate in mm/min (Note mm/min NOT mm/sec)

## Laser module configuration

# See http://smoothieware.org/laser

laser_module_enable false # Whether to activate the laser module at all

## Temperature control configuration

# See http://smoothieware.org/temperaturecontrol

# First hotend configuration

temperature_control.hotend.enable true # Whether to activate this ( "hotend" ) module at all.

#temperature_control.hotend.thermistor_pin 0.24 # Pin for the thermistor to read

temperature_control.hotend.heater_pin 2.5 # Pin that controls the heater, set to nc if a readonly thermistor is being defined, H-BED

#temperature_control.hotend.thermistor EPCOS100K # See http://smoothieware.org/temperaturecontrol#toc5

#temperature_control.hotend.beta 3950 # Or set the beta value

temperature_control.hotend.set_m_code 104 # M-code to set the temperature for this module

temperature_control.hotend.set_and_wait_m_code 109 # M-code to set-and-wait for this module

temperature_control.hotend.designator T # Designator letter for this module

temperature_control.hotend.max_temp 450 # Set maximum temperature - Will prevent heating above 300 by default

#temperature_control.hotend.min_temp 0 # Set minimum temperature - Will prevent heating below if set

temperature_control.hotend.sensor pt100_e3d

temperature_control.hotend.e3d_amplifier_pin 1.30 # must be a free ADC pin, not a temperature input

# Safety control is enabled by default and can be overidden here, the values show the defaults

# See http://smoothieware.org/temperaturecontrol#runaway

#temperature_control.hotend.runaway_heating_timeout 900 # How long it can take to heat up, max is 2040 seconds.

#temperature_control.hotend.runaway_cooling_timeout 0 # How long it can take to cool down if temp is set lower, max is 2040 seconds

#temperature_control.hotend.runaway_range 20 # How far from the set temperature it can wander, max setting is 63°C

# PID configuration

# See http://smoothieware.org/temperaturecontrol#pid

#Auto tune: M303 E0 S190

temperature_control.hotend.p_factor 22.6 # P ( proportional ) factor

temperature_control.hotend.i_factor 1.065 # I ( integral ) factor

temperature_control.hotend.d_factor 120 # D ( derivative ) factor

temperature_control.hotend.max_pwm 192 # Max pwm, 64 is a good value if driving a 12v resistor with 24v.

temperature_control.hotend.i_max 192 # Maximum value for the I variable in the PID control. This should usually be set to about the same value as Max_pwm

temperature_control.bed.enable true # Whether to activate this ( "hotend" ) module at all.

temperature_control.bed.thermistor_pin 0.23 # Pin for the thermistor to read

#temperature_control.bed.heater_pin 2.5 # Pin that controls the heater

temperature_control.bed.heater_pin 2.7 # Pin that controls the heater (HE0)

temperature_control.bed.thermistor Semitec-104NT4 # See http://smoothieware.org/temperaturecontrol#thermistor, SeeMeCNC Rev 10 heated bed thermistor

#temperature_control.bed.beta 3974 # Or set the beta value

temperature_control.bed.set_m_code 140 # M-code to set the temperature for this module

temperature_control.bed.set_and_wait_m_code 190 # M-code to set-and-wait for this module

temperature_control.bed.designator B # Designator letter for this module

## Temperatureswitch

# See http://smoothieware.org/temperatureswitch

# Automatically toggle a switch at a specified temperature. Different ones of these may be defined to monitor different temperatures and switch different swithxes

# Useful to turn on a fan or water pump to cool the hotend

temperatureswitch.hotend.enable true # enable this module

temperatureswitch.hotend.switch fan # select which MOSFET to use, must match a switch configuration (fan2 below)

temperatureswitch.hotend.designator T # first character of the temperature control designator to use as the temperature sensor to monitor

temperatureswitch.hotend.threshold_temp 65.0 # temperature to turn on (if rising) or off the switch

temperatureswitch.hotend.heatup_poll 5 # poll heatup at 15 sec intervals

temperatureswitch.hotend.cooldown_poll 60 # poll cooldown at 60 sec intervals

## Switch modules

# See http://smoothieware.org/switch

# Switch module for fan control

switch.fan.enable true # Enable this module

#switch.fan.input_on_command M106 # Command that will turn this switch on

#switch.fan.input_off_command M107 # Command that will turn this switch off

switch.fan.output_pin 2.3 # Pin this module controls

switch.fan.output_type digital # PWM output settable with S parameter in the input_on_comand, switched to digital for a more like on/off operation

#switch.fan.max_pwm 255 # Set max pwm for the pin default is 255

## Endstops

# See http://smoothieware.org/endstops

endstops_enable true # The endstop module is disabled by default and must be enabled here

delta_homing true # Forces all three axis to home a the same time regardless of what is specified in G28

alpha_min_endstop nc # Pin to read min endstop, add a ! to invert if endstop is NO connected to ground

alpha_max_endstop 1.28!^ # Pin to read max endstop, uncomment this and comment the above if using max endstops

alpha_homing_direction home_to_max # Or set to home_to_max and set alpha_max and uncomment the alpha_max_endstop

alpha_max 0 # This gets loaded as the current position after homing when home_to_max is set

beta_min_endstop nc # Pin to read min endstop, add a ! to invert if endstop is NO connected to ground

beta_max_endstop 1.26!^ # Pin to read max endstop, uncomment this and comment the above if using max endstops

beta_homing_direction home_to_max # Or set to home_to_max and set alpha_max and uncomment the alpha_max_endstop

beta_max 0 # This gets loaded as the current position after homing when home_to_max is set

gamma_min_endstop nc # Pin to read min endstop, add a ! to invert if endstop is NO connected to ground

gamma_max_endstop 1.24!^ # Pin to read max endstop, uncomment this and comment the above if using max endstops

gamma_homing_direction home_to_max # Or set to home_to_max and set alpha_max and uncomment the alpha_max_endstop

alpha_max_travel 1000 # Max travel in mm for alpha/X axis when homing

beta_max_travel 1000 # Max travel in mm for beta/Y axis when homing

gamma_max_travel 1000 # Max travel in mm for gamma/Z axis when homing

# Endstops home at their fast feedrate first, then once the endstop is found they home again at their slow feedrate for accuracy

alpha_fast_homing_rate_mm_s 150 # Alpha tower fast homing feedrate in mm/second

alpha_slow_homing_rate_mm_s 20 # Alpha tower slow homing feedrate in mm/second

beta_fast_homing_rate_mm_s 150 # Beta tower fast homing feedrate in mm/second

beta_slow_homing_rate_mm_s 20 # Beta tower slow homing feedrate in mm/second

gamma_fast_homing_rate_mm_s 150 # Gamma tower fast homing feedrate in mm/second

gamma_slow_homing_rate_mm_s 20 # Gamma tower slow homing feedrate in mm/second

alpha_homing_retract_mm 5 # Distance to retract from the endstop after it is hit for alpha/X

beta_homing_retract_mm 5 # Distance to retract from the endstop after it is hit for beta/Y

gamma_homing_retract_mm 5 # Distance to retract from the endstop after it is hit for gamma/Z

# Endstop debouncing options

#endstop_debounce_count 100 # Uncomment if you get noise on your endstops, default is 100

#endstop_debounce_ms 1 # Uncomment if you get noise on your endstops, default is 1 millisecond debounce

# Endstop trim options

alpha_trim_mm 0 # Software trim for alpha stepper endstop (in mm)

beta_trim_mm 0 # Software trim for beta stepper endstop (in mm)

gamma_trim_mm 0 # Software trim for gamma stepper endstop (in mm)

# End of endstop config

# Delete the above endstop section and uncomment next line and copy and edit Snippets/abc-endstop.config file to enable endstops for ABC axis

#include abc-endstop.config

## Z-probe

# See http://smoothieware.org/zprobe

zprobe.enable true # Set to true to enable a zprobe

#zprobe.probe_pin 1.29^ # Pin probe is attached to, if NC remove the !

zprobe.probe_pin 1.29^ # Pin probe is attached to, if NC remove the !

#probe.debounce_ms 2 # Set if noisy

zprobe.fast_feedrate 200 # move feedrate mm/sec

zprobe.slow_feedrate 5 # Mm/sec probe feed rate

zprobe.return_feedrate 200 # feedrate after a probe, default 0 is double of slow_feedrate (mm/s)

zprobe.probe_height 10 # How much above bed to start probe

#gamma_min_endstop nc # Normally 1.28. Change to nc to prevent conflict,

#CRITICAL! This sets to MAX travle!!!!!!!!!!!!!!!!!!

zprobe.max_z 536.5667 # Maximum Z (was gamma_max)

gamma_max 536.5667 # This gets loaded as the current position after homing when home_to_max is set

# Levelling strategy

# Example for the delta calibration strategy

leveling-strategy.delta-calibration.enable true # Enable basic delta calibration

leveling-strategy.delta-calibration.radius 110 # the probe radius

# Example for the delta grid leveling strategy

leveling-strategy.delta-grid.enable true # Enable grid leveling

leveling-strategy.delta-grid.radius 100 # Grid radius in millimeters

leveling-strategy.delta-grid.size 5 # Grid size, must be an odd number

leveling-strategy.delta-grid.do_home true # Whether to home before calibration

leveling-strategy.delta-grid.save false # Whether to automatically save the grid

leveling-strategy.delta-grid.initial_height 10 # Height at which to start probling

## Panel

# See http://smoothieware.org/panel

# Please find your panel on the wiki and copy/paste the right configuration here

#panel.enable true # Set to true to enable the panel code

panel.enable false # Set to true to enable the panel code

# Example for reprap discount GLCD

# on glcd EXP1 is to left and EXP2 is to right, pin 1 is bottom left, pin 2 is top left etc.

# +5v is EXP1 pin 10, Gnd is EXP1 pin 9

panel.lcd reprap_discount_glcd #

panel.spi_channel 0 # SPI channel to use ; GLCD EXP1 Pins 3,5 (MOSI, SCLK)

panel.spi_cs_pin 0.16 # SPI chip select ; GLCD EXP1 Pin 4

panel.encoder_a_pin 3.25!^ # Encoder pin ; GLCD EXP2 Pin 3

panel.encoder_b_pin 3.26!^ # Encoder pin ; GLCD EXP2 Pin 5

panel.click_button_pin 0.28!^ # Click button ; GLCD EXP1 Pin 2

panel.buzz_pin 1.30 # Pin for buzzer ; GLCD EXP1 Pin 1

#panel.back_button_pin 0.28!^ # Back button ; GLCD EXP2 Pin 8

panel.external_sd true # set to true if there is an extrernal sdcard on the panel

panel.external_sd.spi_channel 0 # set spi channel the sdcard is on

panel.external_sd.spi_cs_pin 1.23 # set spi chip select for the sdcard (or any spare pin)

panel.external_sd.sdcd_pin 1.31!^ # sd detect signal (set to nc if no sdcard detect) (or any spare pin)

panel.menu_offset 1 # Some panels will need 1 here

panel.alpha_jog_feedrate 6000 # X jogging feedrate in mm/min

panel.beta_jog_feedrate 6000 # Y jogging feedrate in mm/min

panel.gamma_jog_feedrate 6000 # Z jogging feedrate in mm/min

panel.hotend_temperature 185 # Temp to set hotend when preheat is selected

panel.bed_temperature 60 # Temp to set bed when preheat is selected

panel.menu_offset 0 # Some panels will need 1 here

panel.alpha_jog_feedrate 6000 # X jogging feedrate in mm/min

panel.beta_jog_feedrate 6000 # Y jogging feedrate in mm/min

panel.gamma_jog_feedrate 6000 # Z jogging feedrate in mm/min

panel.hotend_temperature 185 # Temp to set hotend when preheat is selected

panel.bed_temperature 60 # Temp to set bed when preheat is selected

## Custom menus : Example of a custom menu entry, which will show up in the Custom entry.

# NOTE _ gets converted to space in the menu and commands, | is used to separate multiple commands

custom_menu.power_on.enable true #

custom_menu.power_on.name Power_on #

custom_menu.power_on.command M80 #

custom_menu.power_off.enable true #

custom_menu.power_off.name Power_off #

custom_menu.power_off.command M81 #

## Network settings

# See http://smoothieware.org/network

network.enable false # Enable the ethernet network services

network.webserver.enable false # Enable the webserver

network.telnet.enable false # Enable the telnet server

#network.ip_address auto # Use dhcp to get ip address

# Uncomment the 3 below to manually setup ip address

#network.ip_address 192.168.3.222 # The IP address

#network.ip_mask 255.255.255.0 # The ip mask

#network.ip_gateway 192.168.3.1 # The gateway address

#network.mac_override xx.xx.xx.xx.xx.xx # Override the mac address, only do this if you have a conflict

## System configuration

# Serial communications configuration ( baud rate defaults to 9600 if undefined )

# For communication over the UART port, *not* the USB/Serial port

uart0.baud_rate 115200 # Baud rate for the default hardware ( UART ) serial port

second_usb_serial_enable false # This enables a second USB serial port

#leds_disable true # Disable using leds after config loaded

#play_led_disable true # Disable the play led

# Kill button maybe assigned to a different pin, set to the onboard pin by default

# See http://smoothieware.org/killbutton

#kill_button_enable true # Set to true to enable a kill button

#kill_button_pin 2.12 # Kill button pin. default is same as pause button 2.12 (2.11 is another good choice)

#msd_disable false # Disable the MSD (USB SDCARD), see http://smoothieware.org/troubleshooting#disable-msd

#dfu_enable false # For linux developers, set to true to enable DFU

# Only needed on a smoothieboard

# See http://smoothieware.org/currentcontrol

#currentcontrol_module_enable true # Control stepper motor current via the configuration file