@HalfNormal

Do you know of a rotary that is adjustable for shot glasses and that it’s able to engrave all the way around a beer mug that has a handle? I just ordered my machine thank you for all your support

I purchased the rotary off eBay. Just do it look on eBay and see if you can see something that will fit your bill. You just might need to purchase a couple of different rotary attachments to get what you need.

No link

Looks like it will work. You will need to get the correct connector or make a cable to interface it to the laser. It is a screw on connector to disconnect the y axis and connect the rotary attachment.

@HalfNormal

I’m trying to order the rotary table but they’re asking me single phase or 3 phase a stepper motor which one is for this machine

Not sure about a 1 phase or 3 phase but the steppers used in this unit are 2 phase bipolar stepper Motors.

@HalfNormal

Would you be able to let me know what power and speed works best for different types of materials that works best for you

Trial and error is the best teacher! Get a lot of scraps and play! Have a notebook handy to write down what works and what does not. Not all lasers and materials are equal so what works for one might not on another. Here is what I do. Start low power and a fairly fast speed. Then start to slow the speed a little then increase power. Back and forth until you get the results you are looking for. I cut a square a few inches square for the template. This the best way to know your machine and materials. Have fun!

Oh yeah, different software will have different results.

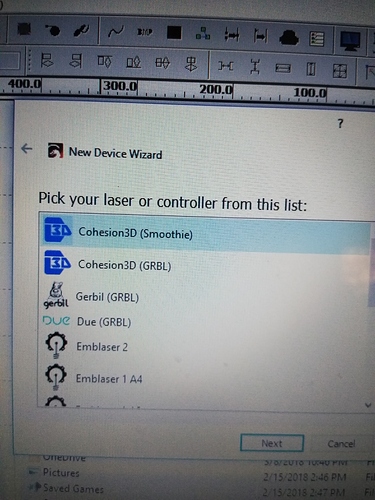

You should have a selection for Rudia

@HalfNormal

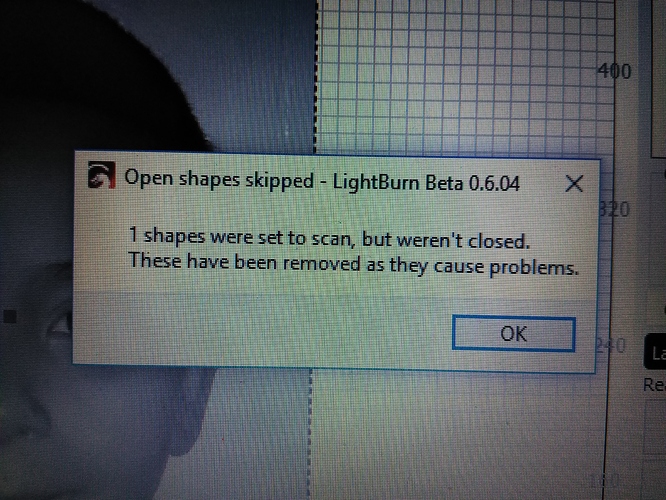

Thank you so much for your help you same me from a big headache. Would you know why every time I put a picture to engraved it pops up this message

You are welcome. Happy to help when I can. I am unfamiliar with that error message. The fastest way to get help with lightburn is on their facebook page. I did try a quick google search and came up empty. Please let me know what you find out.

I restarted the program and it worked good that message only pops up when I import certain pictures. What’s the fastest speed that I can run it? And what the most power I can run ? For safety

There are always a lot of variables on what works and what does not. The lowest power is always the best for safety. Speed is relative to the material and expected outcome ie lighter or darker and type of material. Remember that what worked once on a certain material might not work the same again due to natural variations. I always work with scraps before committing. I wish that you could just set and forget but that is not how the laser works. Keep working with it and it will come easier to find what works most of the time. Most of all have fun!

Hello HalfNormal I have a question I wanted to see if you can help my out with. By any chance do you know we’re I can get the right power supply for this laser mines fried a few days ago? Thank you

@Inland_Empire_Engrav Funny you should ask! Mine also failed but I was able to get a replacement in 3 days. The replacement is plug and play. A bit of advice, when you are resiliconing the lead to the laser, put tape around the bottom or the silicone will want to run out.

I am going on vacation the end of the week and will not have cell service the whole time. I will check my G+ as often as I can to help you out. Here is the link.