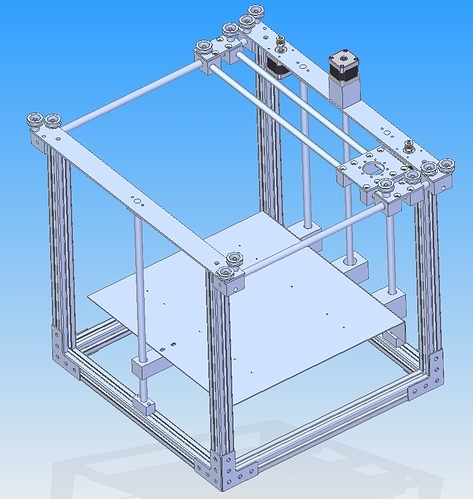

My 3d printer/cnc engraver project!

Looks good, but…

if i take a guess at the measurements of this thing, I think you are heading for major trouble in the z-axis. As long as you are not panning on a heated bed, maybe it could work, but with the extra weight of a big heated platform one nema 17 motor is never going to move the bed reliably.

The laws of phisics will not allow it. elieve me, I tried. And failed. I ended up using 3 small stepper motors for the bed.

Hi @Rien_Stouten the printer has a working area of 385x330x350. The z axis will be moved with two nema 17 motor and TR8x1.5 trapezoidal screw (one on each sides). Theoretically, even if the plane is made by a steel sheet, the 2 motors with 0.55 Nm of torque, are enough.

@Walter_White

Okay, that sounds better, but I only see one motor for Z in your design? Where are you going to place the second motor? If you’re planning the motors parallel to the two guide rails on the same side of the printer, there stil is a problem. If you place the second motor on the opposite side, that could work. But in that case the belts would be in the way? You could place the motors at the bottom of the printer, as I did. But then there is also the problem keeping the bed level? Which could be solved with 3 (smaller) motors?

I have modified the project during construction

Please do keep us posted, since I have built a almost same size printer, I’m very interested in your experiences.

I think that the 30x30 aluminium profile frame is very rigid. If I will have a flexion on the upper sheets, I will weld a ribs.

I’ll keep you updated.