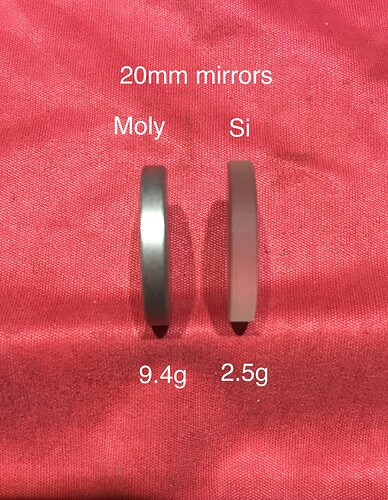

When I first got my K40 about 2.5 yrs ago I immediately purchased new mirrors from lightobjects to replace the crappy stock ones. I had ordered Moly mirrors but I didn’t realize until much later that what I actually got where coated Si mirrors. Fast forward to now and, when I was aligning my new tube, I realized I accidently burned in some paper target residue on the y-axis mirror. Even though I try and take good care of the mirrors the y-axis always gets the most residue build up. So I ordered a replacement mirror from cohesion3d and got a real moly mirror. Received it today and immediately notice the weight difference, ~7g. For the fixed or y-axis mirror this would not be a big deal, but it got me thinking about the x-axis mirror which moves a lot more especially in raster engraving. Seems to me that the extra weight could cause more backlash issues with accel and decel. Thoughts?

I don’t think that a 6.9g weight difference will cause any noticeable problems, especially since there is probably a bigger difference than that in the weight of the carriage and belts from one machine to another.

If that weight is a problem I would argue to your drive is marginal.

I agree that in the grand scheme of things the weight difference is small, but I was thinking that a lighter head is better in general. I assume that more weight also causes more wear and tear. Not a huge issue but just something that ran across my brain when I felt the weight of the mirror.

I can’t see 7gms (or 1/4 ounce) making any difference to the X axis movement, even when the dynamic weight increases when the carriage direction changes from right to left and vice versa on raster engraving.