Yeah, I can find those set/grub screws in the US too. But no other kinds of screws so far…

Wouldn’t those be usable? They would give you the option to scew on a counter nut without unscrewing the whole screw.

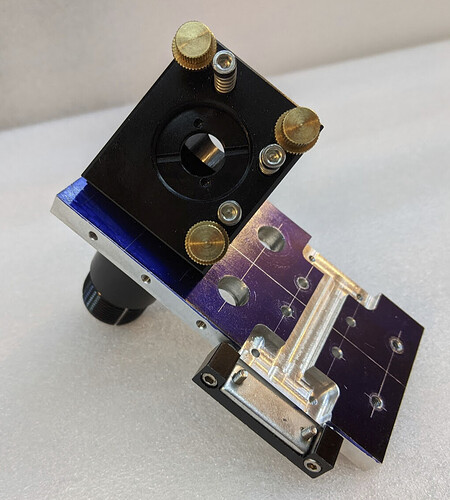

The set screw tip shape is wrong; needs to be pointed to engage with the floating mount. Also brass is softer than steel. ![]()

YES!

“XBM6” tells me English “stage maintenance feed screws” and now I have the initial search terms I need.

“9S7C-18” leads me to “micrometer screws” as well.

Thank you! ![]()

Updated the OP now with images of the first and second mirror assemblies. If anyone is interested in playing with models while this is still WIP, let me know.

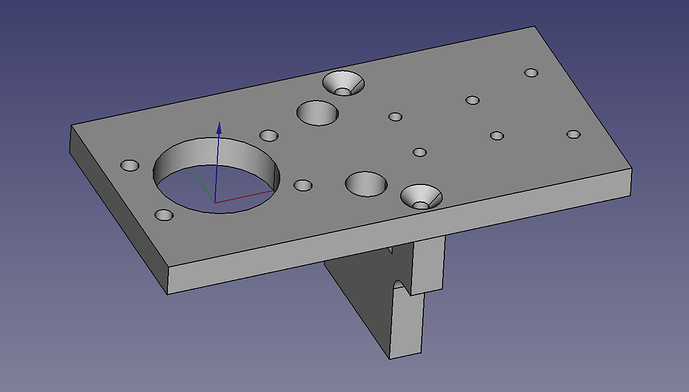

Did a good bit of the laser head tonight. The mirror stage, angle block, tube components down to the nozzle (not including the air attachment) are modeled and pushed to the git repository. No threads modeled, and I didn’t bother with the internal lens holder for now. Still have the bracket to model, though there I’m less motivated because I think I need to make a different bracket to match the linear rail I’m using.

I really want to get this finished soon so that I can pull it into the overall model to make sure that the dimensions will work before I start cutting extrusion.

I haven’t modeled the bracket yet, and it’s hard to get excited about starting, because it’s not a good fit for the monocle. I should do it some time in December if I’m going to, though, before I might have to update to a new version of SolidWorks to keep using the academic license. (Not sure exactly how that works, just got a warning that I need to renew the academic licensing.)

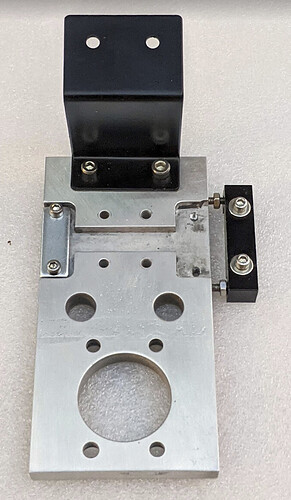

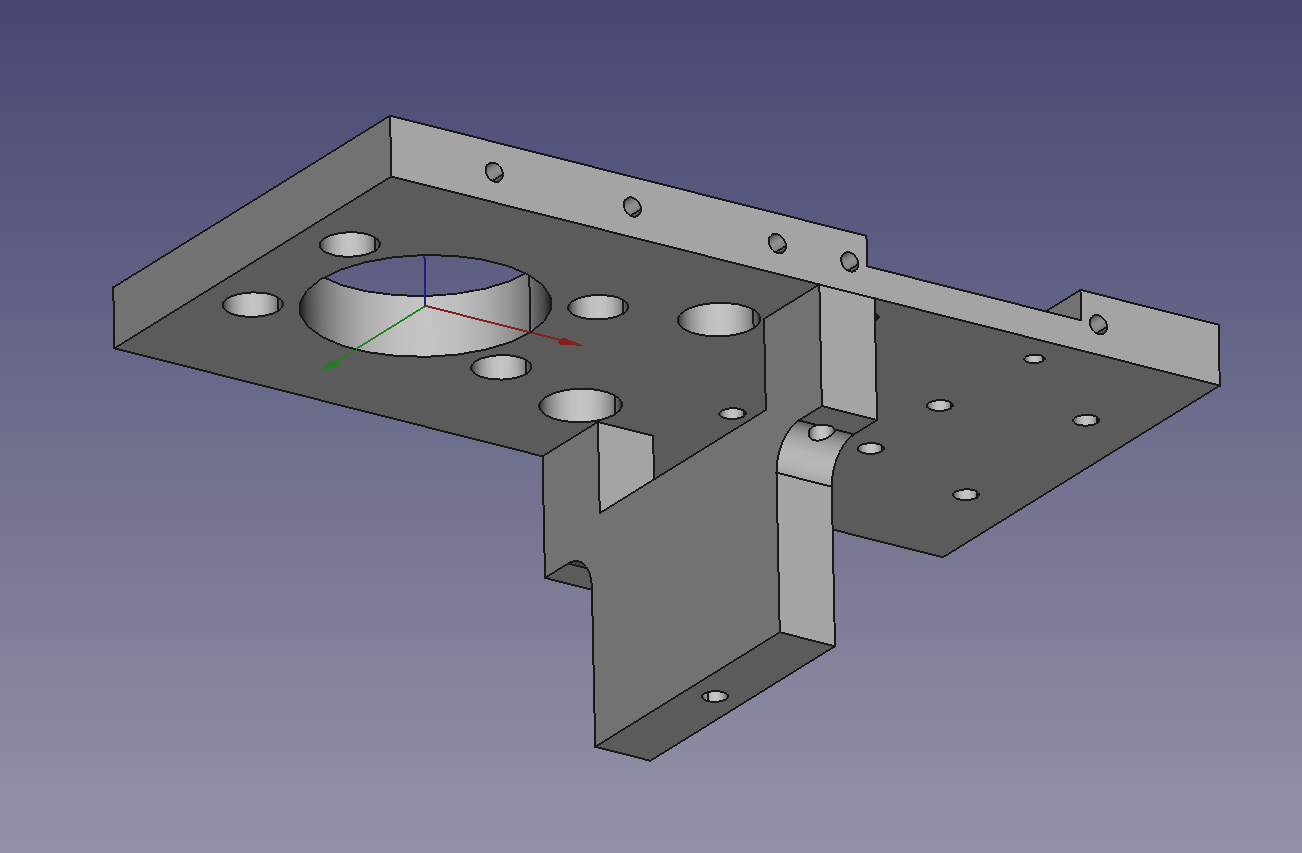

In the meantime, I made an alternative bracket that is designed to print or machine. I’m starting with printing, but may well cut it out of aluminum later once the design is proven. Here it is, done with the realthunder branch of FreeCAD:

The 3D printed bracket isn’t as stable as I would like.

Also, I worked out that the intended linear rail for the cloudray C head is HGR15, because as far as I can tell it is the only type of linear rail that has M4 holes on a 26mm square. If I hadn’t already purchased MGN12 rail I would just use the bracket that came with the cloudray set, and if anyone follows after me here to make another monocle, that should be the norm. In fact, HGR15 rails can be bought for $90-$100 for two 1500mm sections with four carriages, which could be cut up and be enough rail for the whole thing as long as you don’t want more than about 700mm Y travel.

But since I already have different rail, I thought I’d use my measurements to make a replacement part with mounting holes appropriate for MGN12-C with 20mm x 15mm M3 mounting holes.

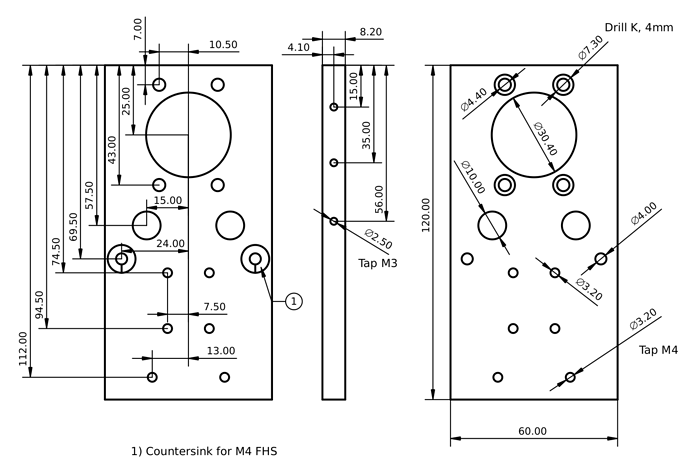

When I tried to assemble it, I discovered two small errors in the model; one was that the countersinks for the laser head mounting screws are slightly too deep, and the other was wrong screw spacing for the belt clamp — I’m not sure how I measured that wrong from the model, and at least I got the holes on the side for the belt tensioning clamp right. Washers will solve the too-deep countersink, and I can work around the belt clamp problem one way or another, maybe just making a new clamp using my mistaken measurements.

I also broke an old drill bit in one of the holes on the side, so now I’m boiling it in alum to dissolve the drill bit and finish the job:

Sorry, off topic. What’s this about dissolving a drill bit?

Interesting. I see a number of references like this one from hackaday.

Seems clock makers are in the know. Any experience @funinthefalls?

So alum is ammonium aluminum sulfate. Aluminum sulfate will react with iron. I think using alum is just because it commonly available. Just Aluminum sulfate, with out the ammonia would probably be more effective as you are making sulfuric acid to attack the iron. The aluminum part, the drill bit is in, is passivated so does not readily react.

This alum is labelled as potassium aluminum sulfate. @NedMan would you expect that to be better or worse than ammonium aluminum sulfate?

It definitely didn’t work in 30 minutes. It’s still cooking. It’s much better than it was, but I can’t cook it overnight. Maybe just leave it in there and turn the stove back on in the morning.

Oh, I see. Hmm…I don’t think there would be much difference between potassium and ammonium based alums as far as dissolving steel.

Next time I’ll use a crock pot overnight, and a different container that I can put the whole part into. The surface was damaged slightly where it stuck out of the water, and turning off the stove for the night precipitated alum onto the surface of the glass inner vessel that I haven’t completely removed. Some alum escaped the glass vessel and I had lots of work to do with scotchbrite to fix the saucepot. Took a bit of work with emery cloth and scotchbrite on the bracked to make it look presentable.

I filled the belt clamp mounting holes with jb weld, and tomorrow or so I’ll drill new holes in the right place.

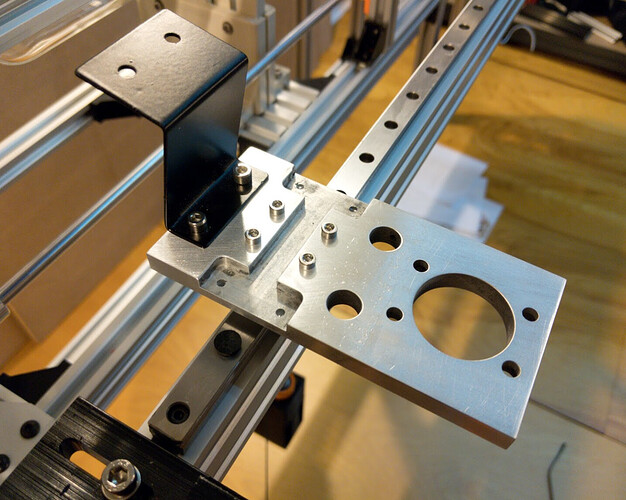

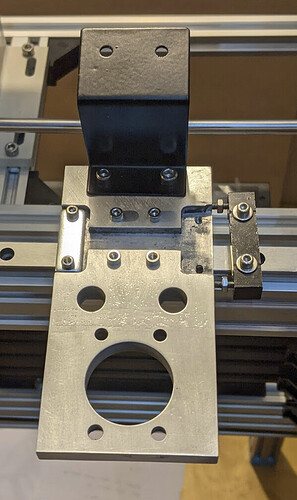

Here it is, test-mounted on the linear rail:

So you ended up dissolving out the bit?

Mostly. There was junk left in the hole, so when I tapped it, it turned out rather loose. However, I don’t actually know what that hole is intended for; I was just copying the part and figured if it were important later it would be nice to have it already done. And I was curious to do the experiment on a part that didn’t matter very much; worse case I could make another one. It has enough features that it’s a little tedious, but it’s not hard work.

Filling in the tapped holes with JB Weld, letting it cure, and redrilling and tapping worked well. Here’s the usual blurry cell camera picture that shows the overlap.

Here it is with the hardware attached:

Installed on top of the rail, now moved to the top of the gantry:

After all that work, I realized that moving the belt to the top was going to cost me some X and Y travel. So instead I’m first trying to use the belt position I came up with initially. I’ll drill two more holes for M4 screws to attach a belt fixture. A typical 40mm x 9mm belt clamp screws into the bottom, holding the belt in place. (This part could still be 3D printed trivially enough, but I’m going to use the mill.) The cut-out at the top goes around the carriage.

The new design, done with the latest realthunder build of freecad, is pushed to the repository. I haven’t cut it yet.

I mis-measured something, so I drilled the mounting holes in the laser head block such that the belt block piece was 2mm too close to the laser tube.

I’m going to leave the current block for if I ever decide to run the belt on top as is often done (using the belt clamp fixtures that came with the original block) and just make a new plate without the top belt groove and belt clamp holes for my current belt setup that looks more space-efficient:

Here’s my print, such as it is (if you know what you are doing, sorry if your eyes bleed when you look at my prints):

Edit: updated print for latest changes; one actual change in dimension, and a few missing dimensions and annotations added to the print, after making the latest version.