You are correct @Gregory_J_Smith , for what you pay and get, it does as promised, cut and engrave the basics: acrylic, wood, plastic, paper, even your finger should you choose to. However it’s the limitations that I’m bumping against.

For one, I don’t own any Corel software, I’m not about to go buy it, nor do I fancy using the pirated copy that’s provided with the machine. I DO however own the full suite of Autodesk CAD software as well as the full suite of Adobe products. These are what we use at my office to drive our large CNC machine. For example, from Illustrator, we simply submit one single, native illustrator file to the spooler. That file has lines of different colors, telling the CNC what it’s cutting, what it’s engraving, and what it’s creasing (for folding.) The color also determined what tool it uses, whether it’s the high speed rotary cutter, the oscillating knife, or the creasing roller. The driver identifies and handles it all. The same goes for a native DXF AutoCAD file.

Now I fully realize that this is all in the driver for the CNC and not so much the controller, however the controller still needs to know how to handle the commands and what to do. But this is also why I said, in the end, I may just decide to roll my own driver/software.

Come back to the laser cutter: there is no reason the same thing can’t be applied here. No reason you can’t ‘print’ a gradient and have the driver instruct the controller how to manage the laser’s output settings for that. No reason I can’t send a single job out of Illustrator that tells it what to engrave and what to cut, as one single job, as opposed to what I currently have to do which is to engrave first as one job, and then cut as a second job. That to me is just dumb.

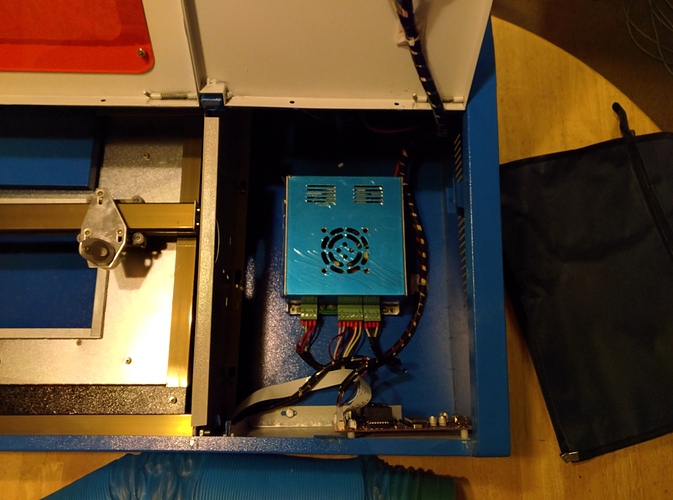

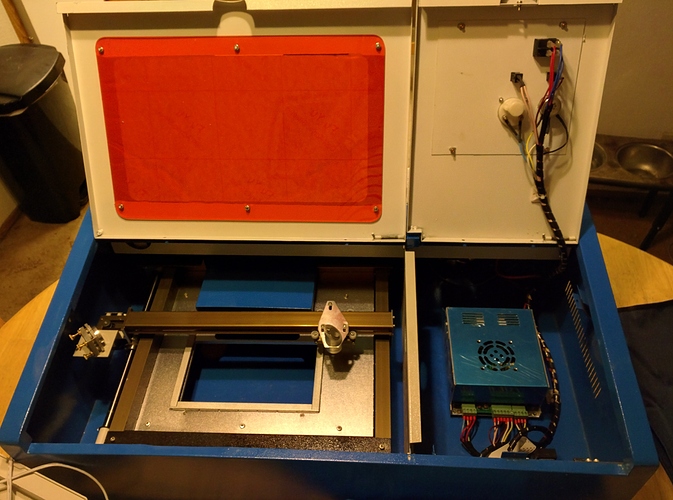

The other reason for me to move to a DSP is the possibility of adding additional hardware later using the same controller, for example a z-controlled bed, or a rotary tool. I know the stock controller that came with my system does not have that ability at all, no additional pins, headers, or anything. So yes, an upgrade is in order.

mine is still complete stock, works but it’s really not worth the time to work against moshidraw. If you value your time change controller board as soon as possible. I am too lazy, so my life is a hell, that’s the main reason I have not used mine for 6 months.

mine is still complete stock, works but it’s really not worth the time to work against moshidraw. If you value your time change controller board as soon as possible. I am too lazy, so my life is a hell, that’s the main reason I have not used mine for 6 months.