Hello,

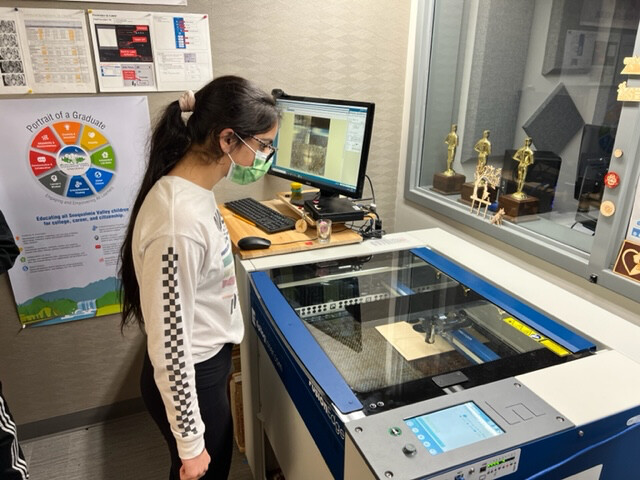

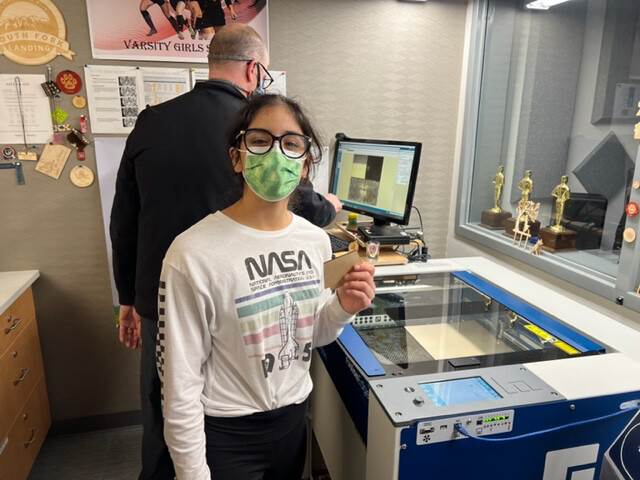

I teach a stem program that is disguise as a rocketry club. Last year I took my students to the High School to use the Laser Machine to manufacture fins and centering rings for their rockets. The students used TinkerCAD to design the parts and Adobe Illustrator to print.

The Vice Principal of Technology was so impressed, he acquired a Ten-High 440 Laser Etching Machine from another school district. Needless to say, this machine lacked certain functionality and equipment.

Sadly it requires an outdated version of CorelDraw and USB sentinel to run the machine. I bought the USB sentinel and I have scarified an older laptop to get it running, so far this is not a good solution for an education environment, but works for a hobbyist.

My school district uses Adobe products and I need this machine to function in that world. Multiple teachers might use the machine for CTE programs.

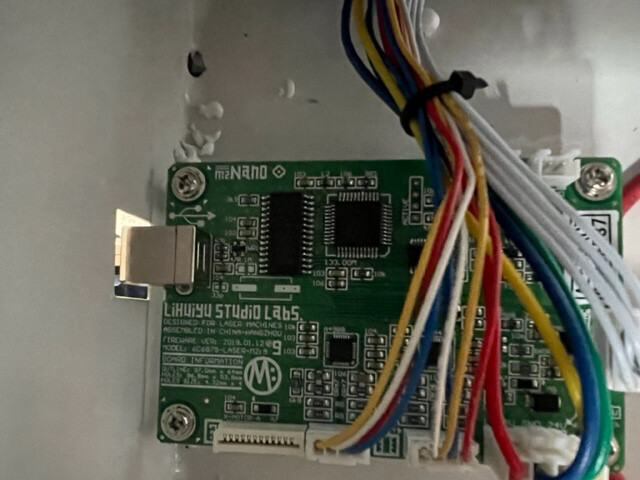

Omtech makes a Light Burn compatible mother board for K40 printers.

I am assuming the Ten-High 440 is a K40. This machine has a M2 Nano control board. Again LightBurn is not a school approved software which brings me to other controllers, such as the, " OMTech RDC6445G Ruida Control Panel Kit" found on Amazon.

With the current configuration, the software is cumbersome and the USB sentinel will get lost. I am looking for a solution that a student can run with adult supervision, but can perform R&D for class projects.

Please share your thoughts and suggestions,

Warm Regards,

Marshall