Making Multibot Printer Easy

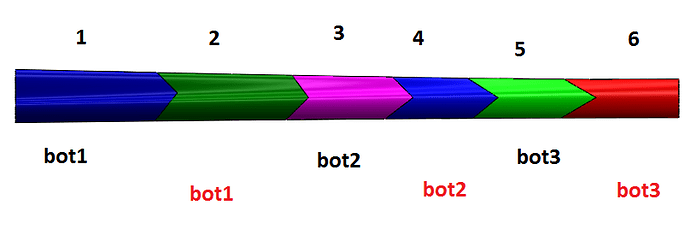

Here is my simplest idea for collision avoiding on a multibot printer: we simply have to split the long body to even number of chunks as double of number of bots. This way we let the bots print first the layers of the odd chunks then they switch printing the even chunks. By this mean collisions are not possible.

We slice the multibody part and split the generated GCode to separate files one for each chunk. The conductor sends each layer code to the corresponding bot and when all done the conductor steps the Z.

I hope this will encourage some go ahead building their multigantry 3D printers.

This is why I’ve always loved you @shauki ; you’re one of the few left that is continuing with pushing weird ideas forward.

you should move the chunks by half chunksize for each layer to avoid structural problematic seams.

@Ulrich_Baer my gut says a relatively small overlap (maybe 50x layer height) should more or less reach an asymptote where further overlap doesn’t add much. Would be interesting to see some experiments on it

Unfortunately, you will end up with a wall for the any particular nozzle to go back to if you print all layers. If you mean to do all the left sections for layer 1 and then all the right sections for layer 1 and then all the left for layer 2 and then all the right for layer 2 and continue on like that, I think that should work. There may be a bit of downtime like Thantik said. There may also be the seem like Ulrich said and his idea of shifting over a little each layer may help a little but it will still leave a line on which it will leak. It will just be a little stronger. At least for our typical filament squirting printers. For laser or binder type printers, this method will probably not have any weakness lines or the prints would be much much stronger along those lines.

One thing that I figure for filament printing is that Z layer height settings will trigger less extra time and the print should probably be set for longer layer time so that the edge is still hot enough for a good bond when the other nozzle gets in that area.

Along the line of what Ulrich said, if you stagger by a larger amount but only for odd number layers, there should be a much greater interface zone. This could be compared to how they have wood cut to have fingers that fit in the grooves between the fingers of the other piece…or two hands clasping with fingers interlocked.

And now it seems that I mis-recalled what Ulrich said while typing up this large post on my phone.

for laser systems they already use muliple beams and binder have these jet printhead with hundreds of nozzles. Also a new laser matrix system for plastic is in development with an array of some thousand seperate laser diodes each melting a dot.

@Ryan_Carlyle yes you are probably right in regards of stability, i just thought shifting half the way would distribute the seams evenly throughout the part like a brickwall - a zigzag would also be fine. I remember a multi robot printer system which just used a diagonal seam on the junction.

Mutual love to this community. @ThantiK please feel free to create a Google blog where you can invite as many authors as you wish (similar to http://beambuilder.blogspot.com/). Feel free to create one called like “CollectivePrinting” and add me as an author - then I shall post there my build and questions.

@NathanielStenzel I did mean print each single layer of all chunks, odd then even and after the part layer is complete move the Z.

I agree with @Ryan_Carlyle and before I start programming I want to see if the imperfectness of hot end movement can achieve that effect naturally without shifting X when streaming.

@Ulrich_Baer my picture is in the XZ plane, so I did cut the chunks to fulfill your idea.

http://beambuilder.blogspot.com/