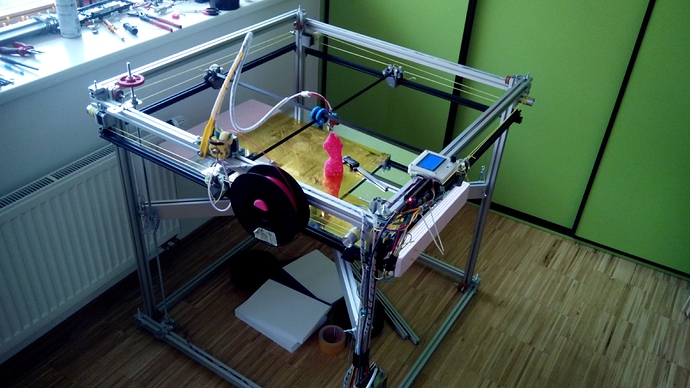

Lot of small changes here, 2mm dyneema (450kg strengh), stepper position to the top, mounted ramps, new cable management (not final). New hotend from http://3draty.cz. Preloaded carbon square rods. Here is my first retraction torture test with great #saintflint extruder

Always thought that having bananas in the background helps significantly on retraction…

Why are the motive behind the Dyneema diameter change?

It wasn’t necessary but my previous line has no spec. I found some flexible behaviour … but it comes not from the lining but from my PLA printed mount plates. I bought thicker dyneema mainly for Z stage and to make preloaded carbon rods, and will need to upgrade for metal mount plates.

I’ll be interested to know how you’re preloading the carbon rods. Are you forcing the dyneema inside to follow a V shape?

I am impressed by the day by the quadrap and I also like your setup. I see that large span of the printhead printing bike parts or even fabric :).

I have a couple of questions though: 1) how do you put tension into the dyneema fishing line when it creeps; 2) do you pre-creep the fishing line (initially it gives a lot when tensioned); 3) Because this is such a large single string going around I don’t think there are any effects of the “string walking” on the motor pulley but in any case, have you ever noticed any such thing?

Thanks.

@Florian_Ford Sorry I don’t understand technical meaning of the term creep or pre-creep and brute google translator doesn’t help either. In the movement path - stepper pulley - groove bearing - x/y carriage I made a tension just with my hand and ear … looking for the same deep frequency played on the 2mm dyneema string. But with my PLA printed plate mounts for steppers I found that with too much force applied they bend causing stepper motor axis not perpendicular to the movement plane and if the axis is not perpendicular “string walks” much more on pulley … even falling out of 50mm long pulley. So I have ordered metal mounts and will upgrade this weak part.

@Karel_Cernohorsky You should use the parametrized spool I’ve made for my printer… I have no problem of creep nor walking whatsoever!

Since they’re printed they offer a lot of grip. Just print at 0.1 for better definition.

https://cad.onshape.com/documents/a638fd246ea648248dda5595/w/278a24d25594400d81cf36af/e/6a362e5b7f2a4a92b4bd8dd5

Look for Drum 18 mm.

@Michael_Memeteau right now I am unable to print it … and I am not ready to give up my nice & shiny alu pulleys from @shauki

Ok. If you decide otherwise, I can always send them to you (for free of course).

@Karel_Cernohorsky

Can’t explain in better and forgive my blunt explanation, which is a link to a pdf explaining the term: http://is.gd/jVJEtw

BTW some people pre-creep thair spectra/dyneema by keeping it under some weight for certain amount of time, maybe days I don’t know exactly.

@Florian_Ford @Karel_Cernohorsky Sounds as if the simplest way to explain what “creep” & “pre-creep” is would be to say “Stretch” & “Pre-Stretch” of the fibre. From the PDF Florian provides, this seems to be the case.