I was just on the Makers On Tap Podcast with @mcdanlj and it was a blast. And I realized I have only been posting my progress on my new CNC Router on Twitter recently, and not here. So time to rectify that issue, here is my current progress. I have the majority of my components at the house (only a few had shipping damage  ). Now that I have the parts in hand I can 3D model the majority of the remaining parts, (most don’t have MFG models or prints that I could make models from). I have slowly learned to make the majority of my mistakes in the computer so I don’t have to do too much rework in meatspace.

). Now that I have the parts in hand I can 3D model the majority of the remaining parts, (most don’t have MFG models or prints that I could make models from). I have slowly learned to make the majority of my mistakes in the computer so I don’t have to do too much rework in meatspace.

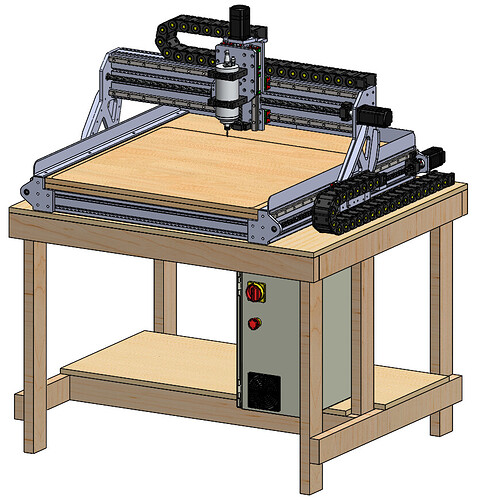

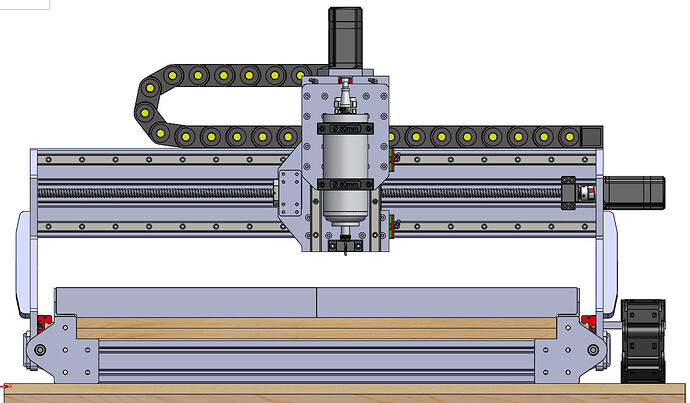

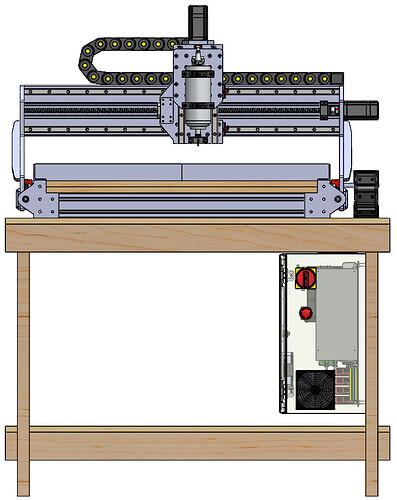

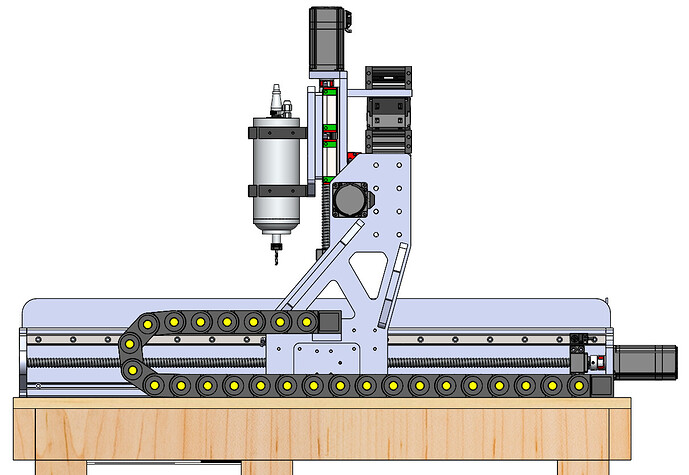

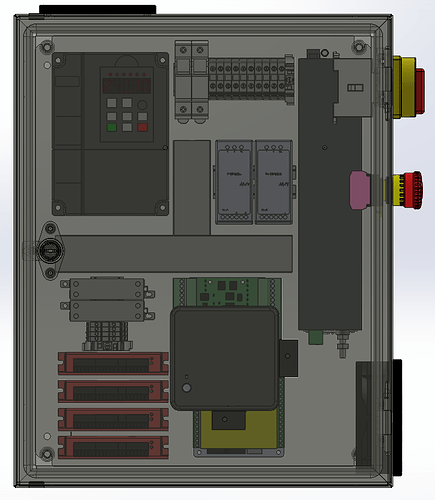

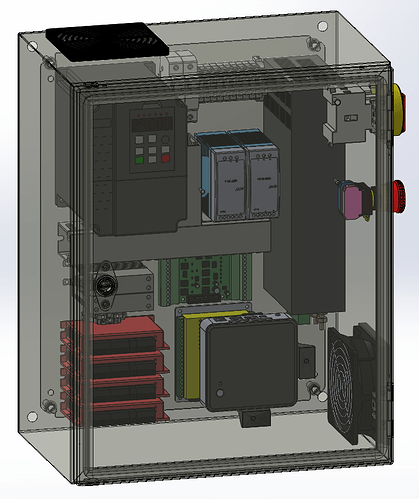

My design criteria is I wanted a strong and capable aluminum cutting router with a round a 30"x30" cut area in X/Y. My current CNC is a beta version of the R7 CNC that Brandon from SMW3D/Hobby-Fab and I worked on together. The R7 is a great machine but I wanted something just a little more robust for more aggressive cuts. I am changing to a 2.2KW spindle with an ER20 collet, and steppers are Nema 24 Closed loop versions. The axis are driven with 5mm pitch 16mm ball screws. And the extrusions are larger 80/20 extrusions, with motion on linear rails instead of v-wheels. For the R7 the C-beam on the X axis has always been a weak point, that and the fact that it runs on wheels which have more play that Linear Rails.

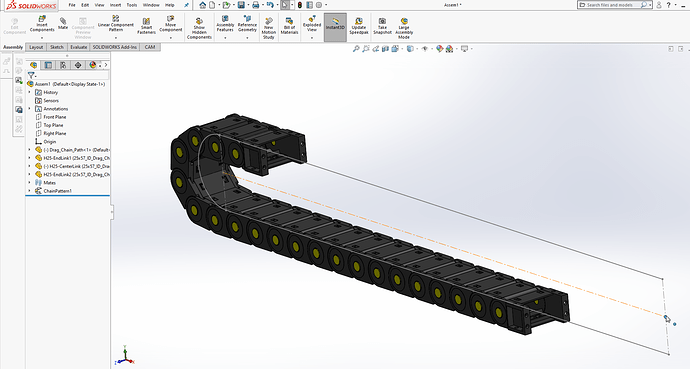

I am also running a new controller. My R7 runs on a Panucatt Devices X5 GT. But this time I went with a CNCDrive AXBB-E controller and the software I will be running is called UCCNC. The only item being reused from my R7 is the water pump, The Intel Nuc PC, and the wood table under the CNC. I am excited, new stuff means more to learn. I had fun today learning how to do Solidworks models for drag-chains correctly to show the path and have them be a dynamic chain that moves within the model.

Anyway, here are some pictures. I would love some feedback.