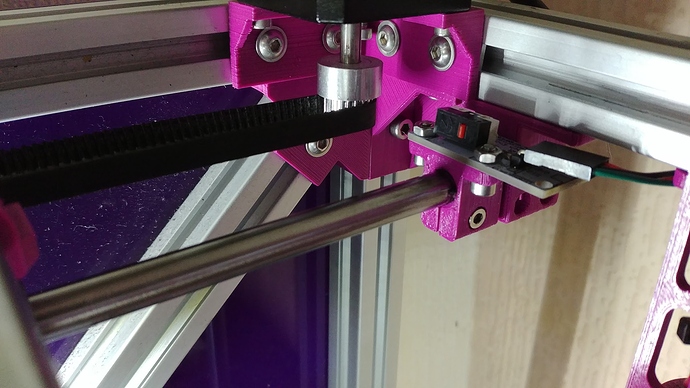

Let’s play a game… spot the issue in the image. Clue: Look at the pulley…

Wait, does the pulley not have a top cap for the belt to sit on?

i worked in place that used lots of pulleys and it is not unheard that the top cap would be missing it is only aluminium plate pressed tight on the pulley.

lol soo gonna slip off…

@Justin_Nesselrotte we have a winner.

I have no idea when or how it happened. I just noticed it. I don’t actually think this was a one from a Chinese supplier, either…

Yep, they can come off like that. I’ve had it happen to me before too.

@Domm434 it’s fine for the moment, I’ve made sure the belt is up against the pulley base and the belts are running straight and are tight.

is the stepper on top and the pulley in bottom. it that model. can you but the pulley upside down and let the belt sit on root of the pulley. that picture don’t give orientation. well it does not take long to get new pulley though.

@Jukka-Pekka_Ylitalo the motor and pulley are as you see it. Unfortunately, the motor shaft isn’t long enough to flip the pulley to keep the belt straight. Not too much of an issue, just need to keep an eye on the printer.

need a gear with side rails to hold pulley in place.

I was going to say the limit switch does not protrude from the mount…

I would not ever build belt an pulley configuration on that orientation. You should try to mod the printer so that the pulley ain’t under the stepper motor. left or right would be better.

@Jukka-Pekka_Ylitalo - It’s perfectly fine. I have 3 FB2020 CoreXY machines running this config with at least 15,000 hours printing between them, in reality, it’s probably a lot more. As for telling me what I should do with my printers and my designs, I’d like to ask you that you refrain from doing so unless I actually ask for feedback. Phrases like ‘you should do…’ are quite irksome when the person saying it does not have the full story.

I apologize for offending you. I did not mean to do that. It just happens to be my really bad habit. To give advice’s when they are not needed. Again i apologize.

@Jukka-Pekka_Ylitalo it’s just something to work on really, no need to feel too terrible. Frankly I have to work on it too. I’ve found adjusting the way I phrase something helps. For example, “I haven’t used a top down design like that for the motor, because I’ve had issues with the carriage weight stretching the timing belts as well as misalignment on the pulley based on the position of that axis” or whatever the reason actually is you dislike it.

For me it is extra hard to phrase. Since English is not my first language. I am from Finland. Yes we do have good English education. But like Finnish is hard language for foreigners to learn. It goes two ways.

@Jukka-Pekka_Ylitalo - S’fine. Don’t worry about it. I just have a mental twitch when I’m told that I can’t or should do something that person’s way, (it’s why I’m self employed) as I’m likely to go and do it anyway or do the opposite of what that person has said.

I also realise you’re not a native English speaker, which is also why I tried to be polite as I could about it.

As for the design, I do realise that it’s not ideal, but when you take into account the whole printer would need a full re-design, just to flip the motors, it’s really not worth it. As the old addage goes, if it ain’t broke, don’t fix it.

Yeah for me it little bit same. I like to design wheel again though some one says it is allready designed. I just like do the design my way. I am new on 3D printing world and first printer i got was Hello bee prusa. Already i have changed those 8825 to RAPS128. I am thinking about Gearing my nema17 and designing new garriage. And doing my own desing of 3d printer that has logic Based on Intel edison that means i need to get get Stepper drivers run over SPI. Not enough pins to run dual extruder config on arduino uno type pin config.

Normally unsolicited suggestions are a bit rude, but you did ask what’s wrong.