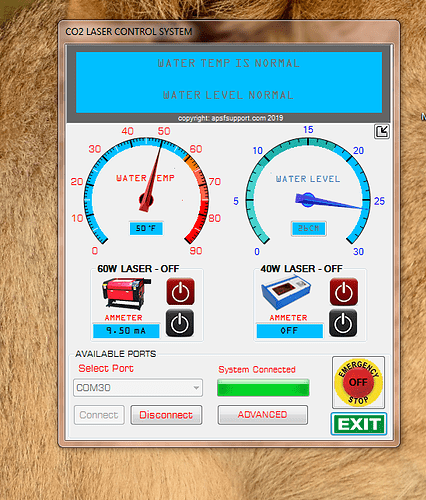

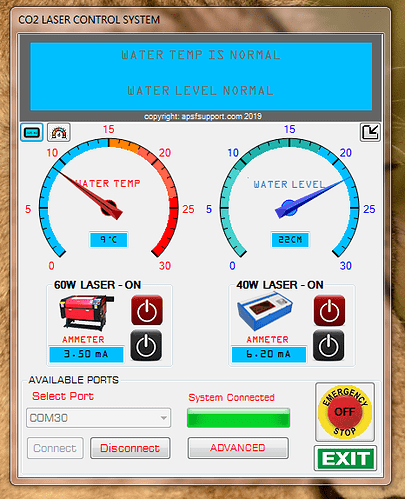

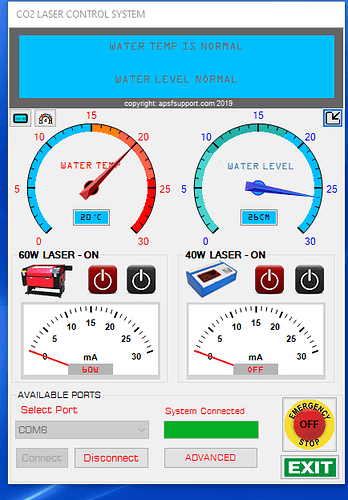

Created my own water temp and level system connected to the machine and powers on/off via Bluetooth. to control if water levels are low and power everything off also temps are too high. and some other misc. settings mixed in. My lasers power on via Bluetooth and also power off no need to touch any power switches. Just launch app and everything powers on. been using it for a year now no issues and works good. interface has changed overtime. also a little tool to adjust Lightburn camera features that are built in to it. like contrast and exposure to fine tune image on windows 7 which I like to use instead of 8 or 10. Lightburn software is awesome.

That’s awesome! Care to share the details and wiring, etc?

Thanks for joining us here! I just did an end-run around the Discourse automatic user promotion system, so I think you can post more pictures now — so we can see all the details. If it doesn’t work, just let me know and I’m sure I can fix it.

Looks really good. Can’t wait to see some more details on this project!

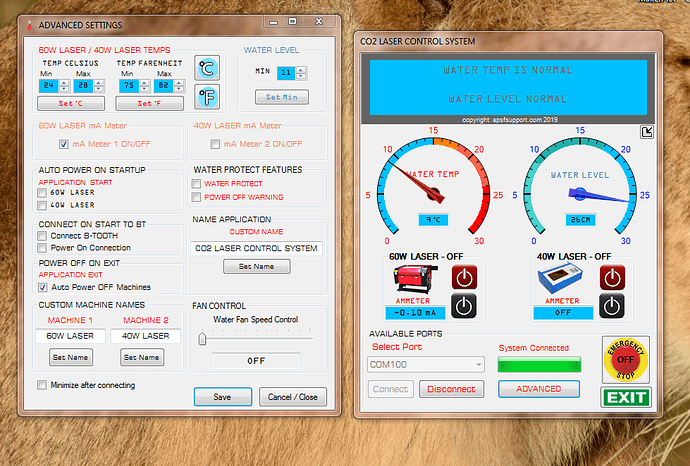

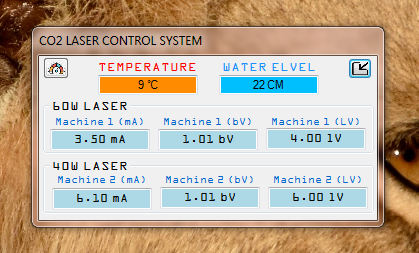

Will add more details once completed, currently adding co2 laser temp reading to read laser tube temps in real-time and voltage to read into the computer not on the machine all the sensors send information via Bluetooth to the computer which in return it is connected to smart power adapters I made to signal power kill incase of any damaging data is received. Currently works without issues at its current state, but needs more features. amp-meter is coded and waiting for chip to arrive should be here tomorrow for the ammeter to read and transmit the code is finished. Now I need to code the real-time tube temperature and limits.

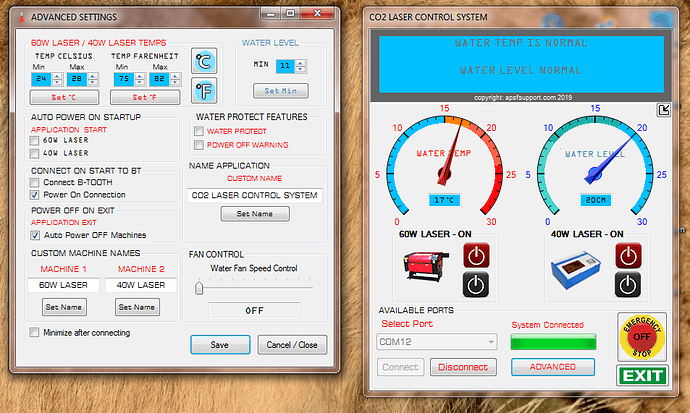

The software remembers the last machine connected. for instant power on to the last connection. com12 is my real machines reading and com100 is the prototype I have on my desk reading temps, levels and amps in real-time. All the features work on the menu.

-

The fan control is a fan over the water that cools the water and assist the cooling system to lower the temperature to about 10C if needed especially in long cutting jobs which has worked perfectly extending the life of the tubes now almost 2 years and that’s heavy use.

-

Custom name remembers the label given to each machine as you can see by the 60W and 40W is the name I gave it. so it reflect on all the menus also coding to change machine image so it matches the connected machine.

-

The temp thresholds are safety the min will trigger a warning onscreen on the app display that the temps are getting high the max will trigger a message display and shutdown powering everything off to prevent damage.

-

The water level threshold is the lowest level to stop the machine if water is too low or to remind you to add water over time.

-

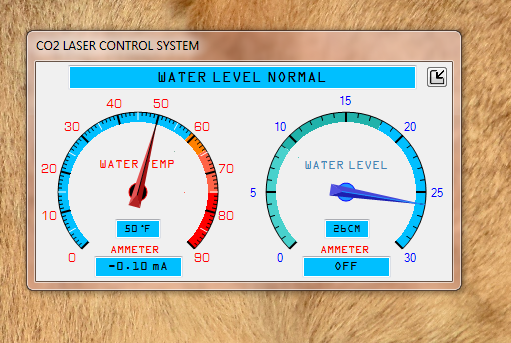

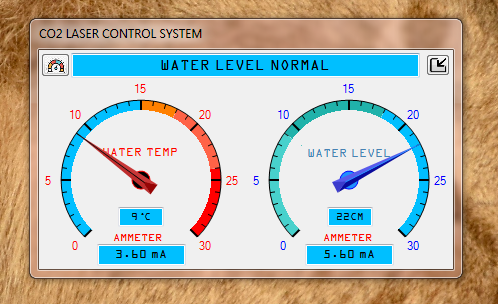

Read and displays temps in Fahrenheit or Celsius.

-

The Connect to Bluetooth just connects the computer to the machine without any other option taking over.

-

The power on connection will power all machines on when connection is established. If not you can choose to power everything on once application launches automatically.

-

The water protect feature is in case there is no water the software will not allow the machine to be powered until water is added or pump is verified working. you can choose to be warned or to power off immediately without a popup warning.

-

When your done and going to bed just have power off on exit so when the computer shuts down or the application is closed everything powers off at the same.

-

Ammeter is of course ammeter that’s is it will be connected to the negative black cable to read and transmit power being used.

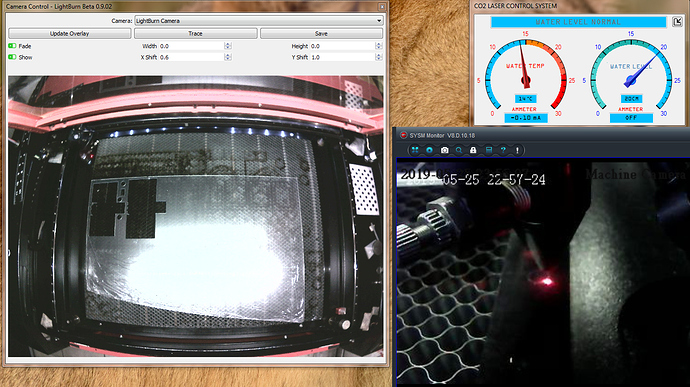

The way I setup is while working on 1 screen say CorelDraw or other apps the other screen showing everything the machine is reading and the cameras on the nozzle viewing current job and the lightburn camera internal displaying the entire case.

reading in Fahrenheit (corrected the spelling of Fahrenheit in the menus).

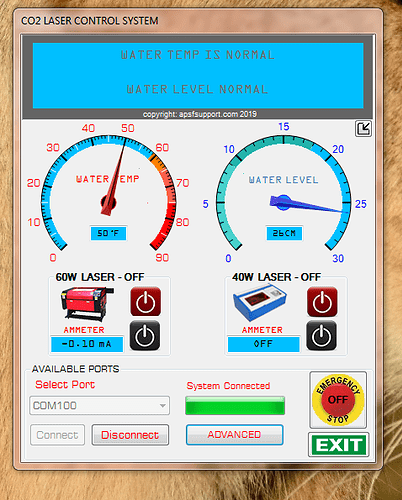

smaller version when you press minimize

screen view

working screen

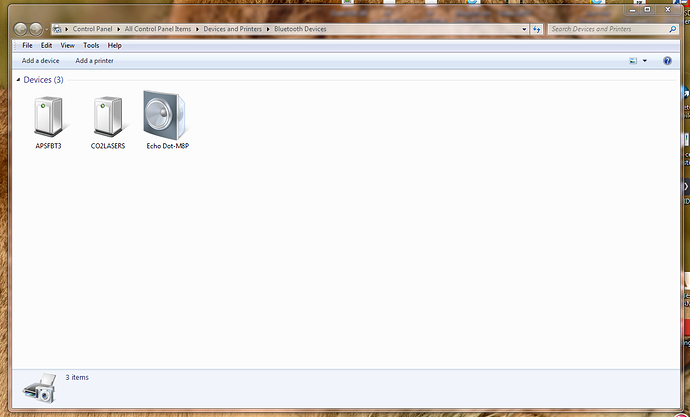

Bluetooth devices listed on the image are custom

CO2LASERS and APSFBT3 are custom bt devices for the lasers.

First test of mA run working properly will test with analog for accuracy.

Both mA meters reading both machines separately. with some changes to GUI

Analog meter