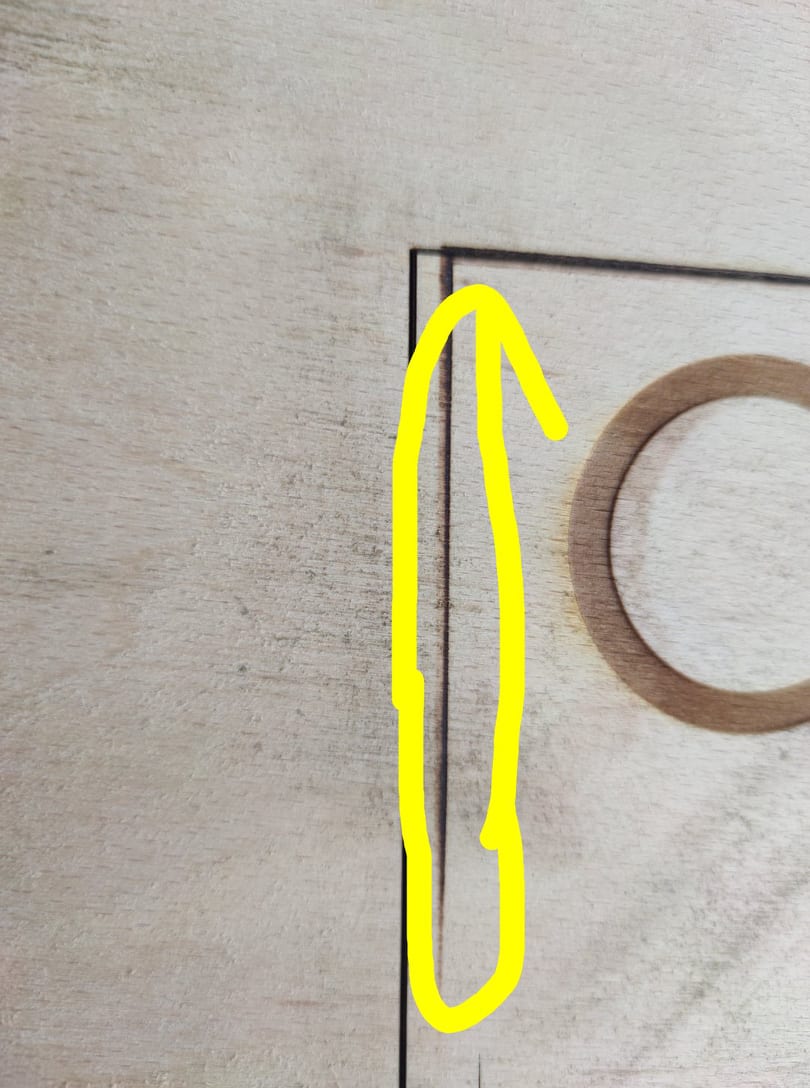

can someone please explain to me why my laser create a parallel line

116430470_205600404226752_1911476572793264646_n|375x500

This is usually caused by the laser beam not exiting the cone correctly, but bouncing off the inside of the cone. You need to align the 3rd mirror so that the beam exits the cone cleanly without hitting the sides.

Thanks for the advice

thanks it really help , but now i have new problem , i cant cut 4 mm polywood with 100percent power 8mm/s 4 pass. before adjusting mirrror after 1 pass in some places it has been cut.

Be careful using 100% power on a machine without a current meter. For the longest life of the tube it’s recommended you keep the tube current at or below 15mA with 18mA being the max. With the digital power controllers 100% can be above 18mA. Before I got rid of my digital power controller 50% yielded 15mA. You might want to check your tube current relative to your digital controller settings either temporality or add in a current meter to your machine.

With trouble cutting, the most common issues are either poor beam alignment or the workpiece not being at the right height. For cutting, the ideal bed height places the focus of the laser 1/2 way into the workpiece.

The quality and type of plywood can also affect cutting consistency.

i am using same height and same plywood like before mirror adjusting mirror

I tried different distances to get perfect focus spot , and still cant cut 4 mm plywood with 4 pass , before adjusting mirror after 1 pass in some places it has been cut.

Well if the mirror adjustment made things worse then I think you need to revisit the over all alignment. Are you using an alignment guide (alignment instructions)? If so which one?

I did it according to this

Do a ramp test just to be sure you are at the right focal distance.

Disassemble the objective lense and look for misalignment, damage to the insides or the lens.