IMHO, all of this has ‘evolved’ from existing commercial equipment and changes are made to lower costs for the hobby sector. Those that can’t afford a $20k machine. A friend of mine that supplies my acrylic (scrap) from his commercial business has an American dual laser tube machine with a Ruida controller. His previous laser had a trocen and it was wired the same as my Ruida. It had an accident with acrylic and honeycomb that ended up in a significant fire in his shop.

The most simple interface is one that is already used by existing, more expensive commercial equipment. On a laser the single most expensive part is probably the controller. Most of the early controllers used a variable dc to control the spindle (spindle speed = laser power). I’ve also noticed that many of the newer or lower cost controllers have done away with the analog control.

The Ruida, Trocen and other commercial controllers have been around much longer than the K40 and it’s associated hardware. They also allow you to ‘store’ the code and don’t require a computer to connected to actually control the hardware.

I think the K40 controller is a very cheap, yet ingenious device. Just by leaving out the ‘laser enable’ signal removes a lot of the ‘head ache’ on what the controller/software has to do. They just make the power a manual control. Removing this from automated control greatly relieves that K40s signal interface.

In the end, they both do the same thing, although I have to admit, the K40 controller/software is really an incredible creation. Always wish I had purchased one. Of course my sights are a bit higher now.

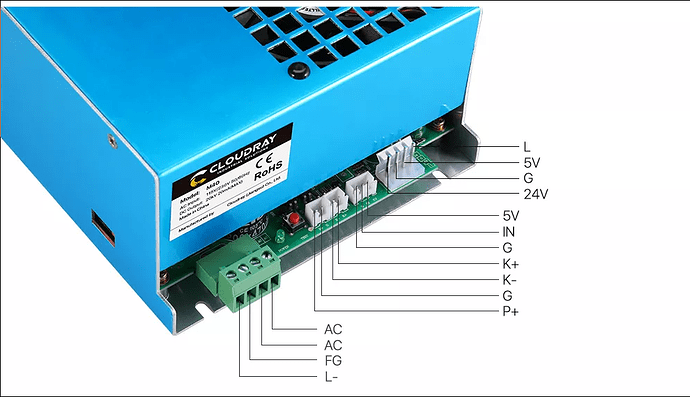

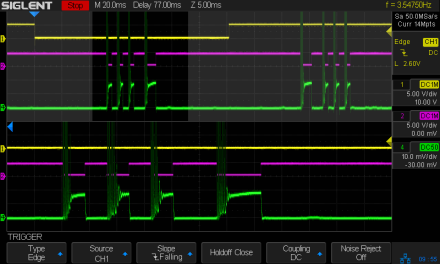

The L-On1 → L is active only when the laser needs to fire. Not sure if that’s what you meant. The pwm is separate and runs for the entire time the layer is executing, even while the head repositions itself to lase another object.

Now that Lightburn has ‘sub layers’ it looks like the same thing happens as it switches to a sub layer that sub layers pwm is immediately present.

The Thunder laser DF212 only has a pwm output and a ‘ttl+’ and ‘ttl-’ for firing control. The - is for the L input, or it’s inverted + for the H input. No analog output…

I understand completely, to me, this isn’t the argument.

In a commercial environment when maintenance is paid for and routinely done, this isn’t an issue. It’s also not wanted in a commercial environment. You have a person with no technical knowledge, monitoring the equipment (maybe 20 of them) as it does the same thing over and over. Having an adjustment accessible to the operator that can damage the equipment is the last thing you want around in this situation.

I’ve had mine for over a year, I check it monthly and I have not had to change the lps settings up to this point. I expect to as it gets older, like me, won’t have a much ‘go’. I use a Mahoney wattmeter or Russ’s dohickey…

You, I and most of the people here are not the average user and certainly not the hired ‘hourly’ worker to watch over this stuff…

I’ll have to admit that I have gone into the Ruida console and bumped the power when I get a run of mdf that has more glue in it. A pot may have been handy there.

Also note if you wanted to use a Ruida for an LED laser that uses the pwm to fire the laser, you would have to add some kind of ‘and’ gate to generate the pwm only when L was asserted.

I wish… but don’t think so… Think we ran out of ideas.

The only part of this issue is that there appears to be a ‘fixed’ amount of time that it ‘fails’ in this way. As you change the speed the area that ‘fails’ is closer of further away. So it appears to me the lps isn’t really shutting down. I sometimes wonder is this is something that can occur with the tubes chemistry and is lasing at a lower power level or …?

I was hoping that @dougl could explain more of what he was talking about for an r/c filter… I’d try anything to ID what’s going on here.

I’d still put my money on the lps…

Sorry about the diarrhea of the mouth… I need to get going…

Talk to you later…

P.S @donkjr the hv meter failed. The resistor stack is apparently not working and I am building another one with higher precision resistors. I think the epoxy must have expanded or shrank enough to break the connection. Figured it was the meter, but it works, who’d thunk it was the resistors. Never thought I’d miss it. Also, I have no equipment to measure 600mOhms