Hi all, does anyone know what would cause my k40 laser to have less output at 100% than at 50%? It won’t make it through 1/8 poplar at 20mm/s 100%. This is a new problem since firing up the machine 6 months after last use. There are no signs of a bad laser tube.

what’s the current at 50% vs 100%?

Machine didn’t come with a milliamp meter. Just went out there and watched the tube to be sure and the arc was bouncing around on the ground side a lot. That end of the tube is tinted brown too. That sounds like a bad tube.

It was arcing on the ground side. Do you mean an arc internally to the tube?

Can you show us a video?

Arc internally to the metal ring in tube that flickers around. I’m not able to upload any pics or videos

What happens when you try to upload pictures?

Do you know how to test for whether your tube has shifted mode?

It says new users aren’t able to upload attachments . And no, I do not know how to test that.

Now I’m able to upload.

Please read through the K40 Intro linked at the top of this page and especially this section:

If you don’t know what current you were putting through the tube and you were setting something to 100%(digital display) then it’s likely the tube is shot.

Put a card or tape in front of your first mirror (but don’t have it touch the mirror!) and test first just enough to scorch it.

Then take a picture of the card and post it here.

To see other examples, you can do a search using the magnifying glass icon at the upper right for “tem01” — TEM01* (donut mode) and TEM01 are the two most common degraded modes for a damaged tube.

To @dougl’s point, it is a disgrace that any lasers are shipped without an analog ammeter; the digital “ammeters” or “power meters” aren’t actually measuring anything on the output and the top of the range can kill a laser tube even if is properly cooled.

I’ve had this laser for over 2 years and used it a lot for making gifts and coasters mostly. It is a preenex (omtech) newer model. I would say I got my money’s worth out of it. It lasted way longer than I ever expected. I’ll do the tape test with it. If the tube is bad, I would put the cloudray 50 watt upgrade kit in it for $230. Do you guys have any input on that kit?Cloudray Bundle For Sale 50W Co2 Laser Tube + 60W 115V Laser Power Sup – Cloudray Laser

OK, the O-shaped mark does look like TEM01* (donut mode). Sadly, this means that the tube has been irreversibly damaged. The K40 Intro that @dougl linked to has lots of information on how to extend tube life as well as sources of replacement tubs.

it’s not unheard of to get 5 years out of a K40 tube but it’s far more likely people will get about 1 year when they don’t have a milli ampere meter and limit max output current to < ~18mA.

That bites. Thank you guys for all the help! Any thoughts on that cloudray 50w tube and psu kit? I will go ahead and install an ammeter (because it’s cheap insurance) and an air assist head. And then

eventually buy a cohesion3d laserboard. I’m sure I’ll be back here for some instruction on installing the new tube and psu if I buy the 50w one.

Cloudray makes pretty good stuff so the only thing of note about that bundle you should be immediately aware of is the tube length and diameter relative to your current tube, tube mounts and chassis size. ie make sure it’ll fit.

Looks like the 50w tube will stick out 15 inches so I’ll buy a true 40w tube from cloudray because it will only stick out 3 inches. Should I buy a psu from them as well? It’s $50.

can’t hurt to have a backup since the LPS is also considered a ‘consumable’…

LightObject has a metal extension. You definitely want a (grounded) metal extension around the tube.

Tube power/current is related to it’s physical size or generally, length. If your current tube is shorter, meaning less power … I doubt the vendor would put anything in there that is superior… but it does happen…

My OMTech China Blue 50W, wasn’t, it made 44W at high current (>20mA), so it was more like a 35 - 40W tube. It was also 880mm in length. The lps was a 60W…

I replaced it with a 40W from Cloud Ray.

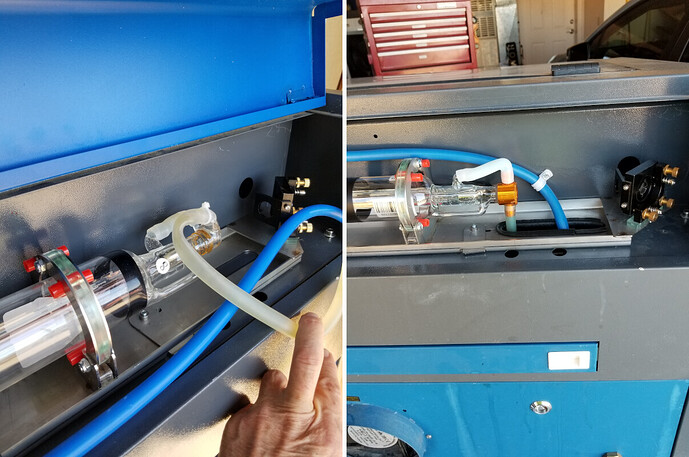

Left is the original coolant right is the above tube. Had another laser, so I took the time of cleaning up the factory job…

It should be easy to check it’s placard, if it has one ![]()

The advantage of a higher output voltage or wattage lps is the response time.

Response time is measured at 90% placard voltage <=0.10mS A higher power tube requires a higher dc voltage for it to lase. A higher voltage lps results in a quicker tube response time…

We are all waiting to see how you did yours… ![]()

Good luck

Make sense?

As @dougl advised, ensure same tube diameter and anything else that effects how the beam is handled throughout the machine.

@mcdanlj advised where you can get a tube cover extension. I could never find one, so I ended up 3d printing one… It’s really on there so the tube doesn’t get bumped or broken, not for anode voltage protection… so metal is the best choice.

![]()