Hi Don,

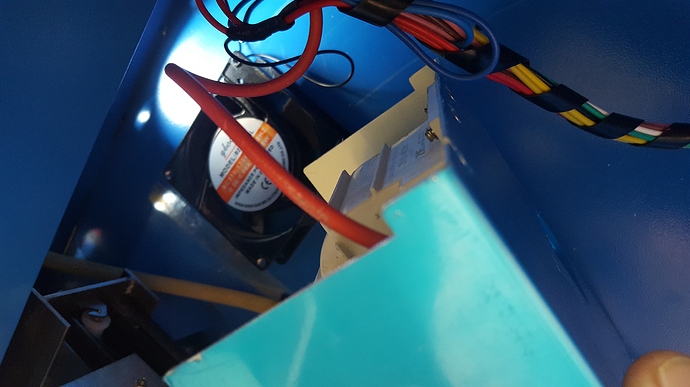

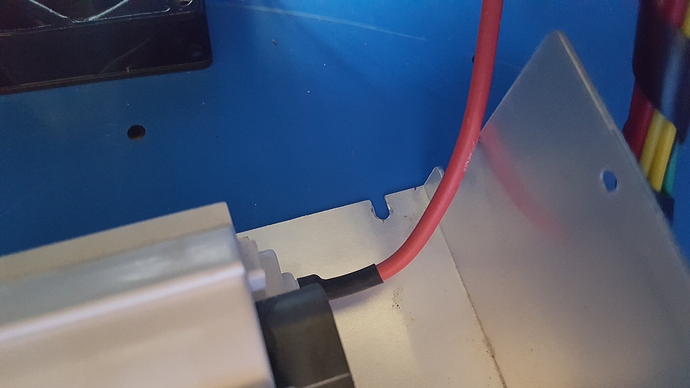

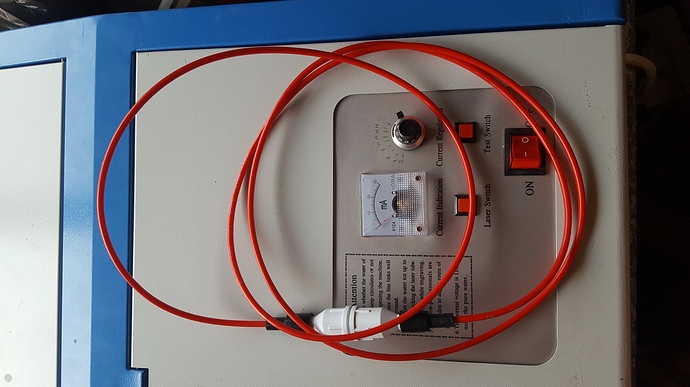

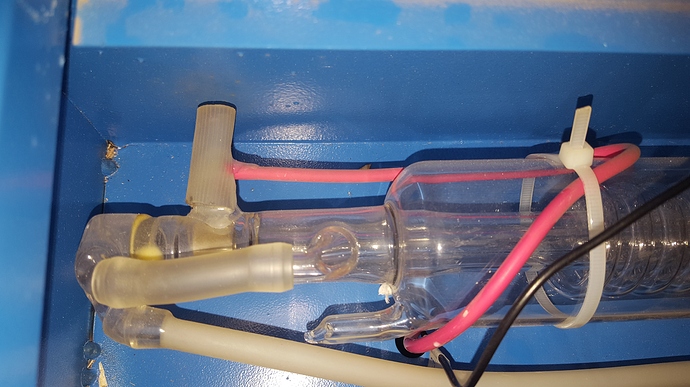

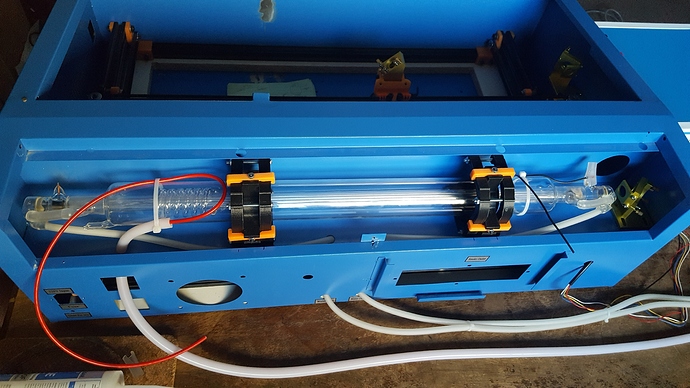

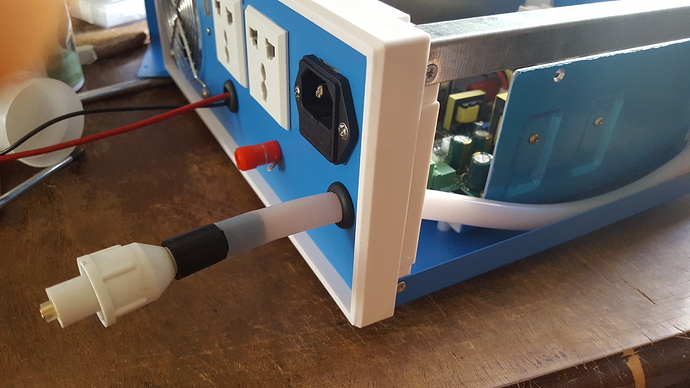

I understand your concerns, and I do thank you for them. I followed this video from the lightobject for wiring the tube. They explain the silicon tubing for the HV wire.

As for the lid switches, I only test fire to find the corners of my piece to get it aligned for cutting. As I mentioned before, I only cut off the outside edge of 1/32" or less, so the sheet’s alignment is critical. ALL cutting and engraving are done with the lid closed.

I’m happy to report that the laser is once again alive. The mechanics work perfectly, but I could tighten the X-axis belt a little bit.

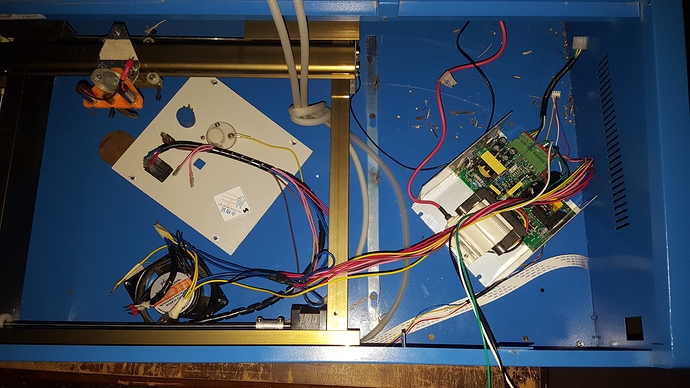

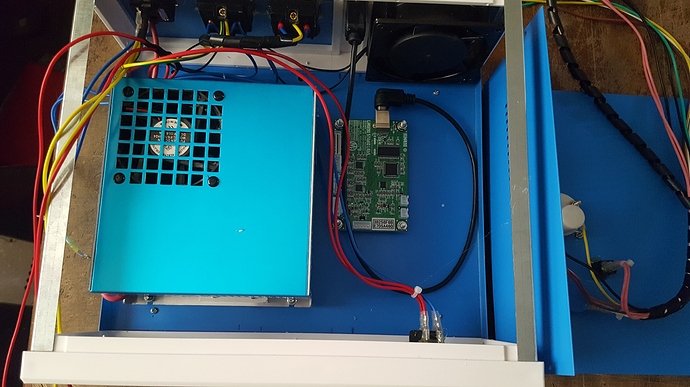

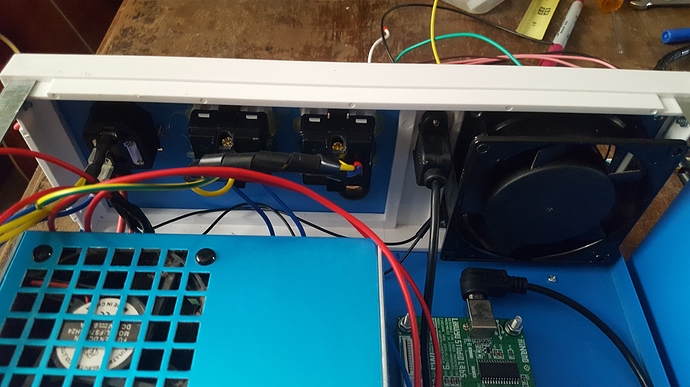

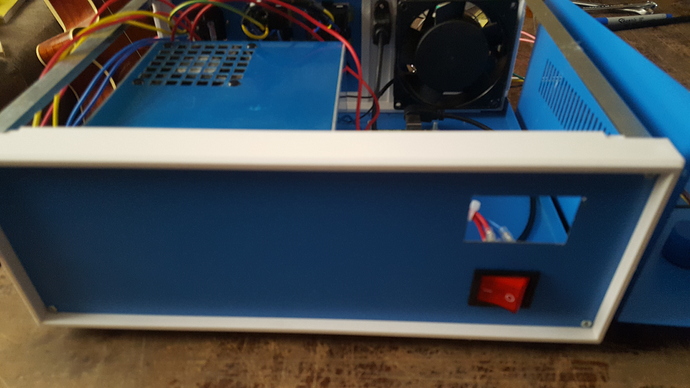

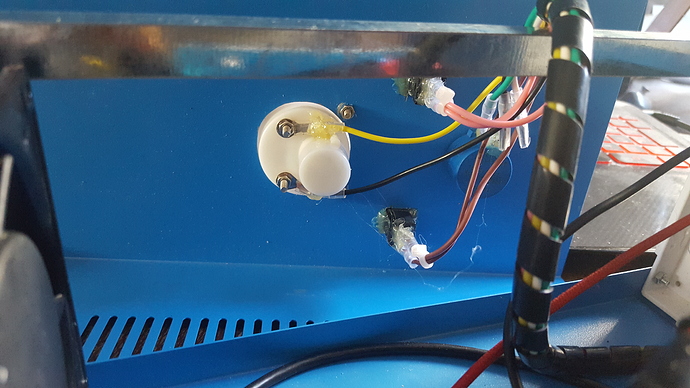

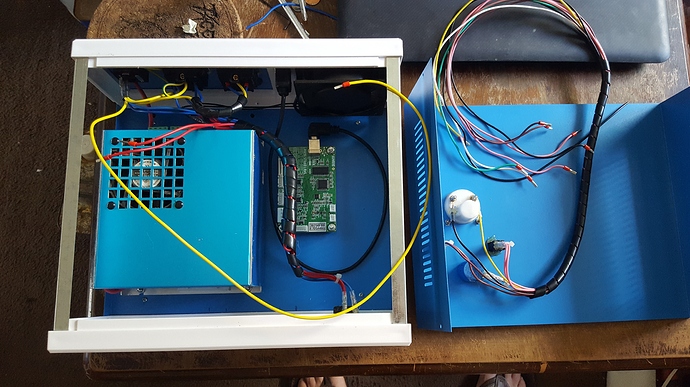

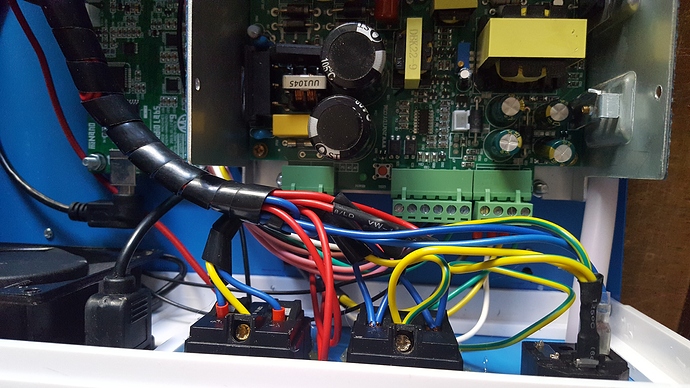

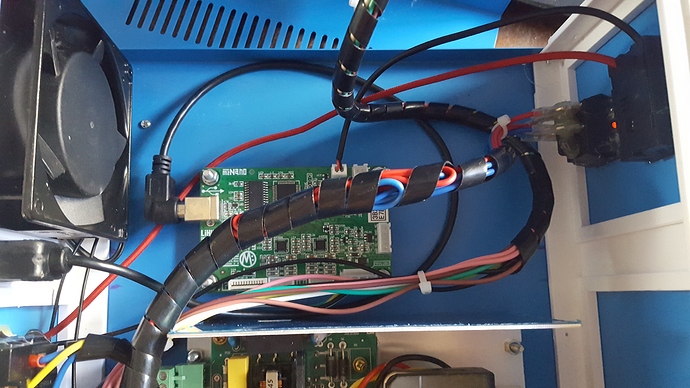

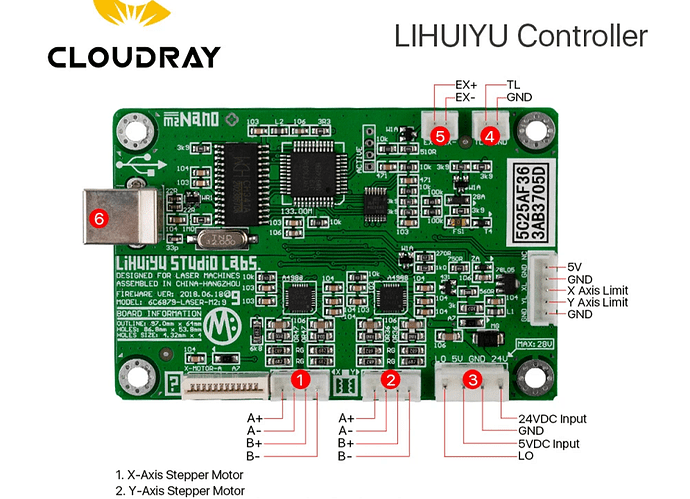

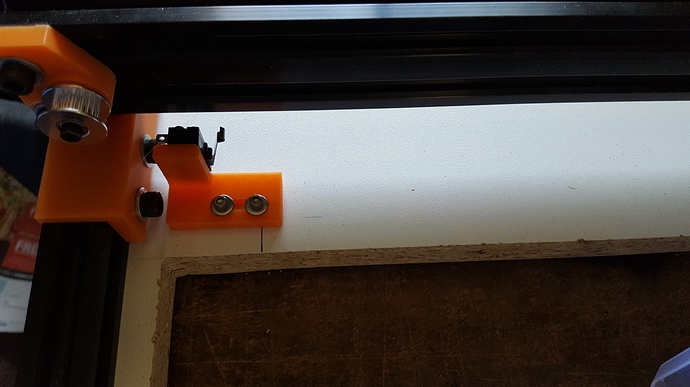

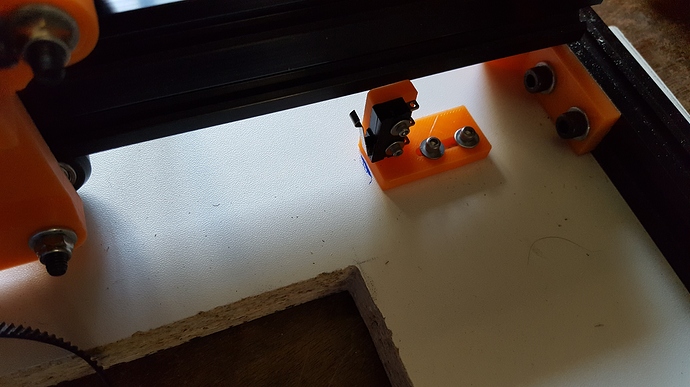

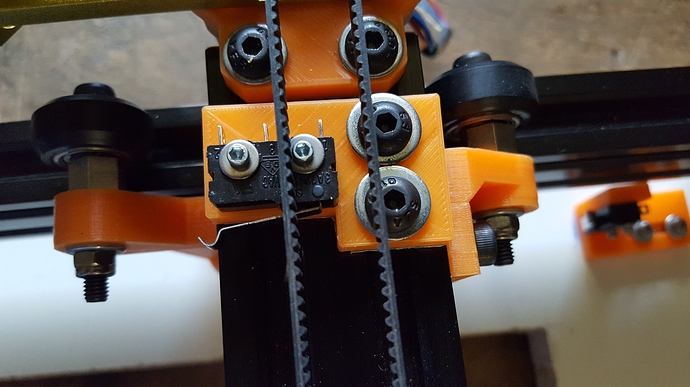

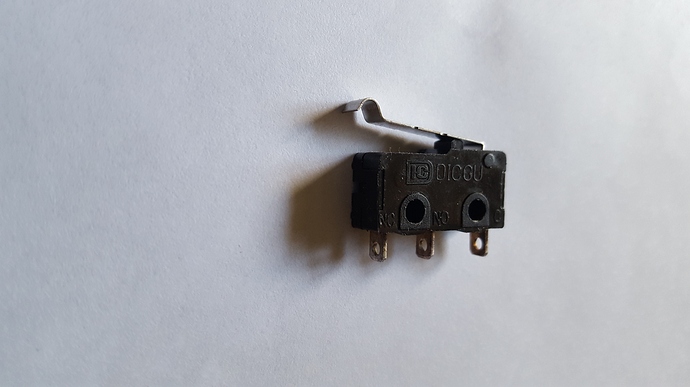

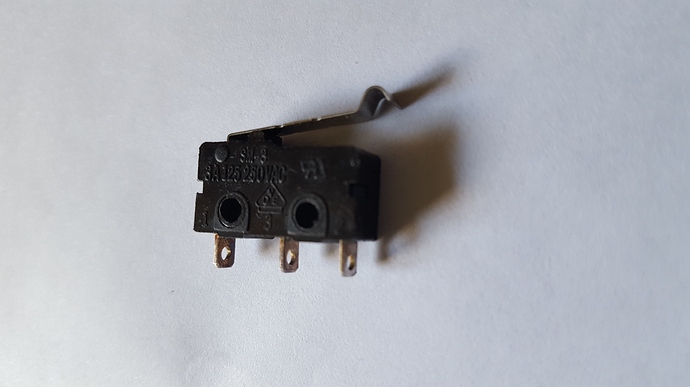

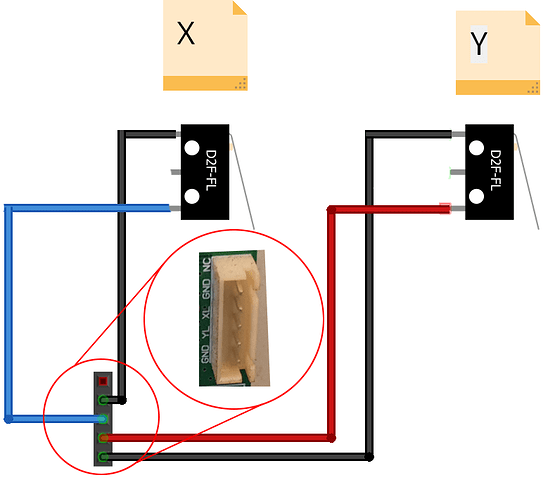

I ditched the ribbon cable along with its optical switches and daughter boards on the electrical side. I added four limit switches, one at each end of both the Y and X-axis, and they work great. They are wired straight into the 5-pin plug, as shown in the picture I previously posted. My only issue with the wiring is that when plugged in, the power switch is always glowing even when powered off. I need to switch the red common and line wires on the button, which should solve that.

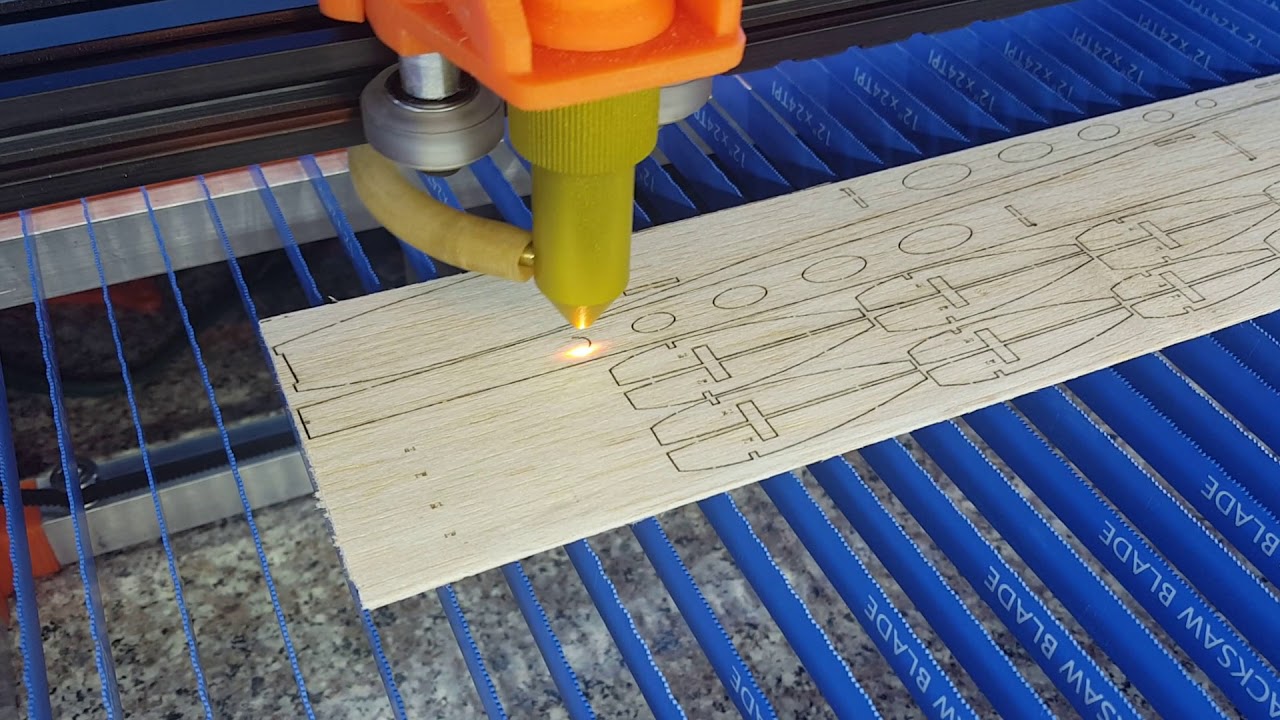

The laser tube works perfectly, and there is no arching anywhere in the circuit. Right now, I am currently aligning the mirrors. It takes a little more time than a stock K40 due to being a little larger, and it’s a bit tighter to work on the 1st and 2nd mirrors. I probably should have bought the alignment tool from American Photonics for simplicity, but I’m a patient guy with time on his hands.

My actual movement came out to be:

X-axis 607.009mm (23.898")

Y-axis - 260mm (10.236")

Here is a couple of videos showing the first homing from the heads farthest position, and one of it simulating etching. There is a little vibration in the X-axis due to the belt being a little loose.

Homing testing the limit switches

Engraving movement test

Once I get the mirrors aligned, I’ll post a video of the machine at work.

Regards

Bill