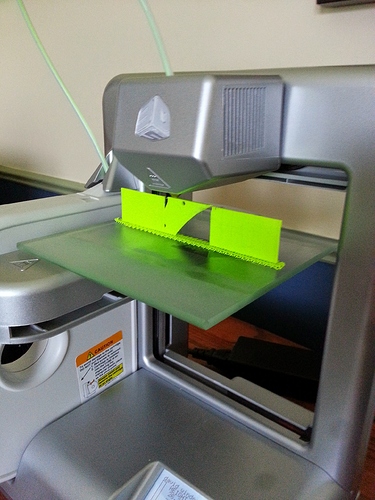

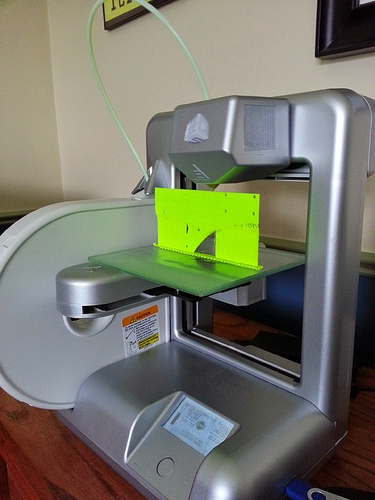

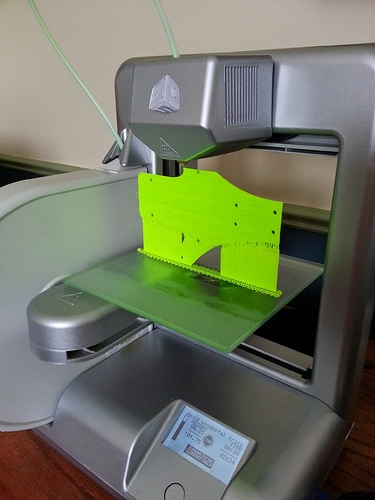

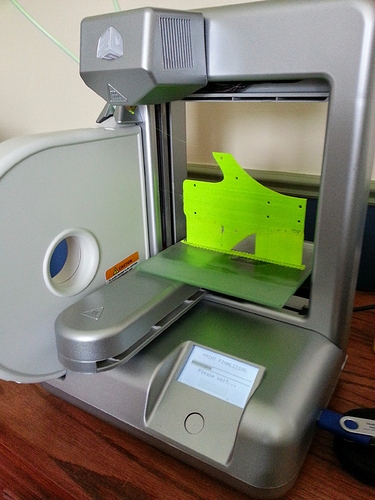

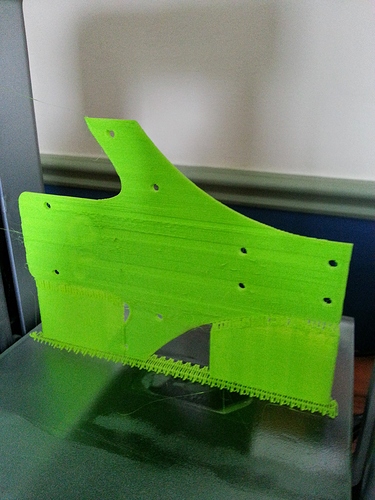

Just finished printing my first successful tricopter frame. I have never been able to print the frame flat on the cube because even with a raft it would curl. I printed it vertically and it worked ok.

#tricopter #3dprinting #success

In still not impressed with the cube but it isnt mine and is all i have available right now. So beggers cant be choosers.

What don’t you like about it? The DIY community has given it a rough ride for proprietary/lock-in filament cartridges, but other than that I have not heard much about its print quality, speed, ease of use, etc.

The ease of use is great if you need something quick and simple.

It definitely serves its niche as a super simple and easy to use 3d printer, which I feel is necessary.

Heres some things i dont like:

-

Software is simple but very very limited. You cant change infill to a percent. There is only solid,partial, (dont know what percent it is), and hollow.

-

My printer has orientation issues. Sometimes even if i change the orientation in the software the printer still prints it the way it wants.

-

Not a huge fan of the supports. Supports dont come off very clean.

-

Settings cant be changed to make prints better. I get some z-banding and cant do anything about it.

I do love that i could just pull it out of the box and it will print within 15 minutes.

Regardless, I am jealous I don’t even have a friend who can show me one of these bad boys in person.

Haha yes fortunately the price is really coming down. I am about to start making a reprap smartrap. My budget (not including filament) is $200 USD. Ill post the parts list and build log here as well as on the reprap forum.

Sounds like you have a lot more tech smarts then I could dream of. Right on!