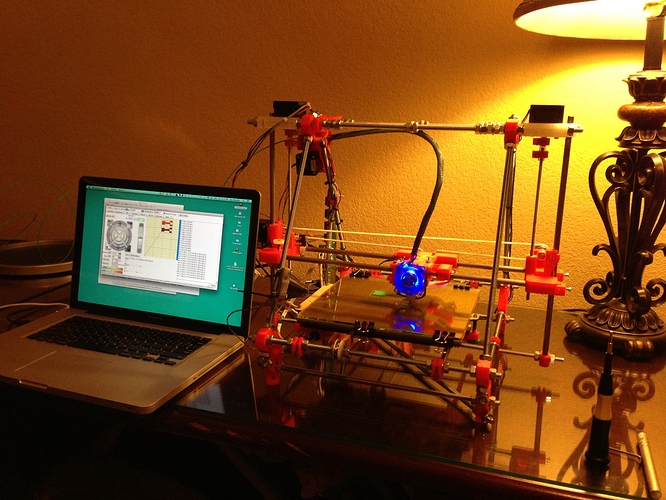

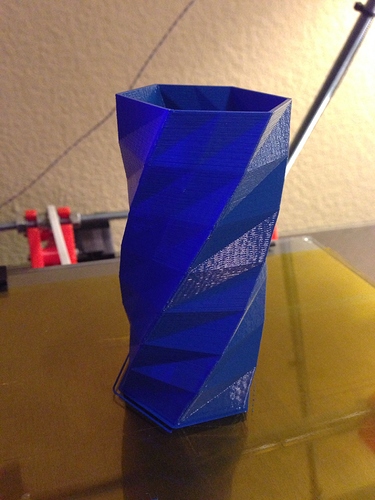

Just finished my reprappro Mendel build. After calibration and getting e-steps tuned I’ve been really happy with the print quality and reliability. Next step build an enclosure and play around with multi extrusion.

This is nice, did you have to do anything special tuning the bowden extruder? I’m considering recycling some QU-BD extruders for a bowden-based second printer but I’ve heard they are tricky to calibrate.

well done

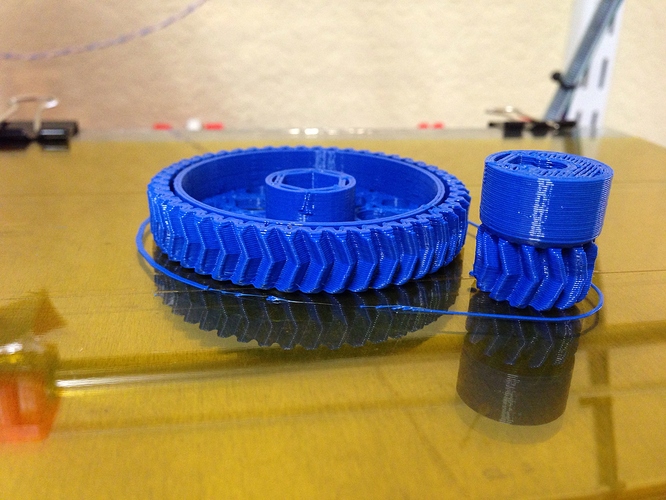

how have you joined the z-motors with the z-threaded rods?

This is my second build and both have been bowden type extruders.So, I don’t have a basis for comparison but I feel like I spent more time getting bed level and print head at the right hight than time spent tweaking the extruder.

@Alberto_Valero_Gomez We use a two part clamp like this http://tvrrug.org.uk/sites/tvrrug.org.uk/files/images/P1020955.preview.JPG

It’s a minimalist 2 piece design that I was sketchy about at first but seems to work well. Close up pic here https://www.dropbox.com/s/v0tgf3zqsa2fhb5/Photo%20Jan%2006%2C%209%2016%2014%20PM.jpg

Great idea!! It’s a flexible coupling!! I must try that!!

@Alberto_Valero_Gomez I was thinking the standard one is http://reprap.org/mediawiki/images/thumb/d/d4/Pm-coupler.jpg/180px-Pm-coupler.jpg

We also have a piece of plastic tubing held between the faces of clamp on the motor shaft, but it holds the z-threaded rod firmly. We use a z-isolator to retain the z-nut and prevent any wobble transferring to the X axis.