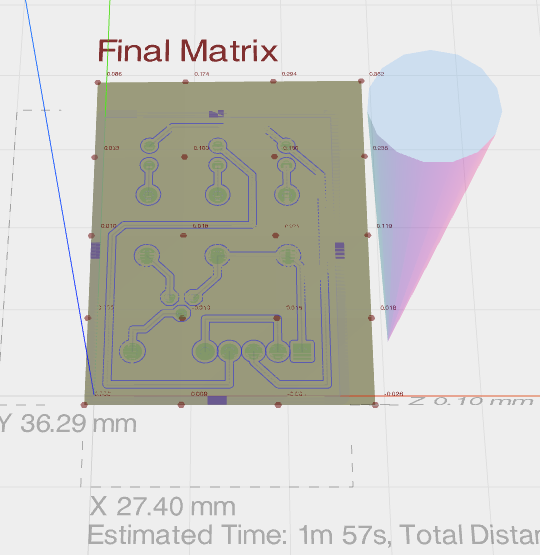

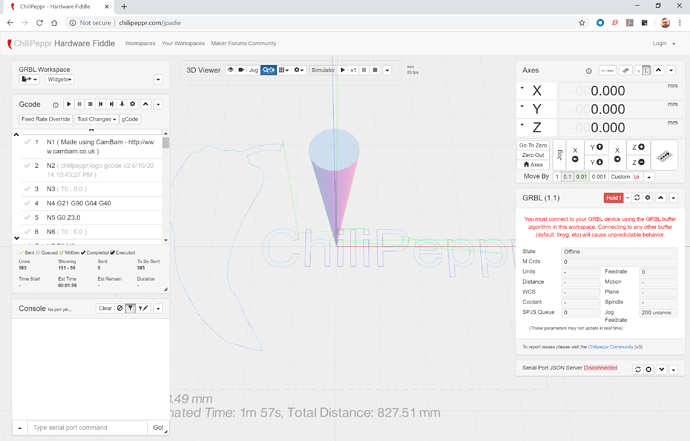

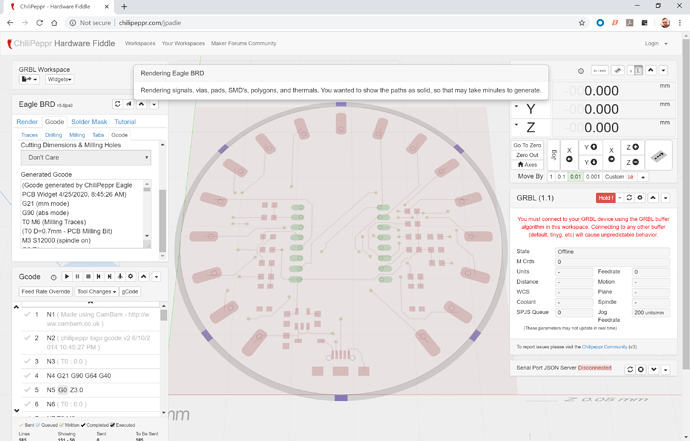

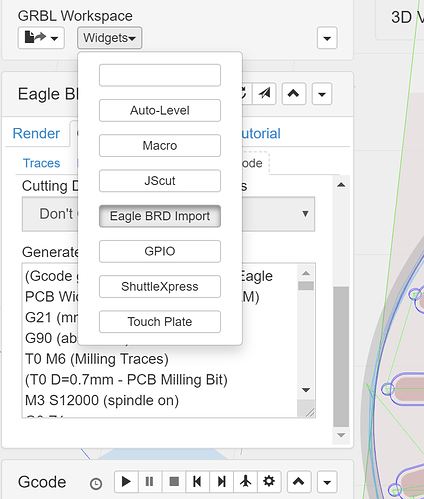

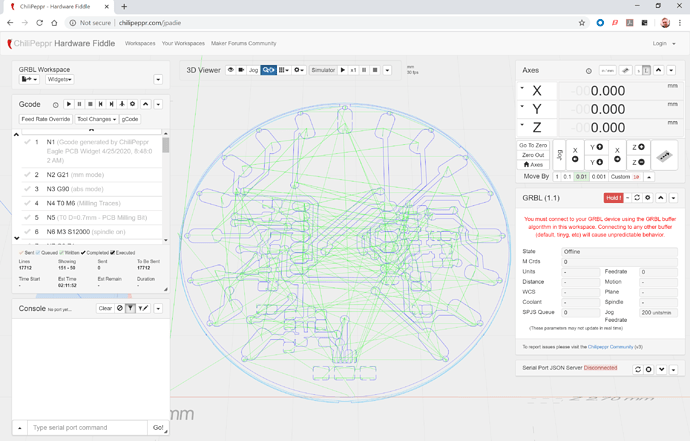

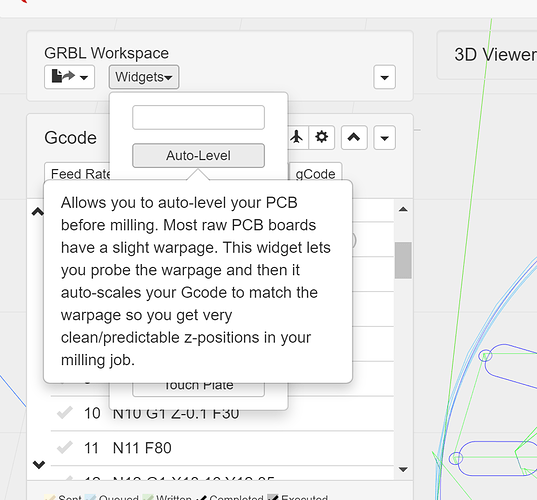

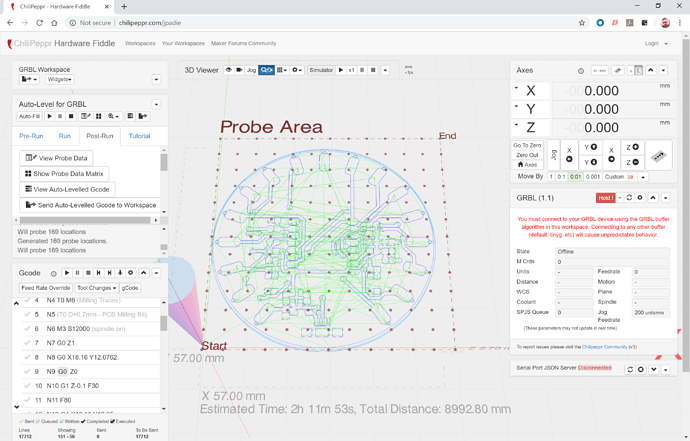

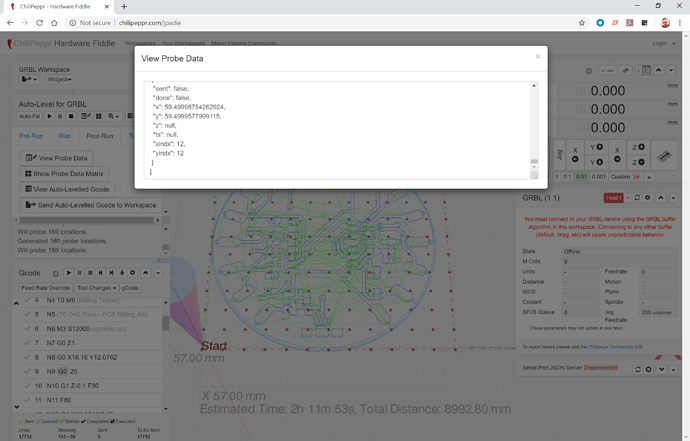

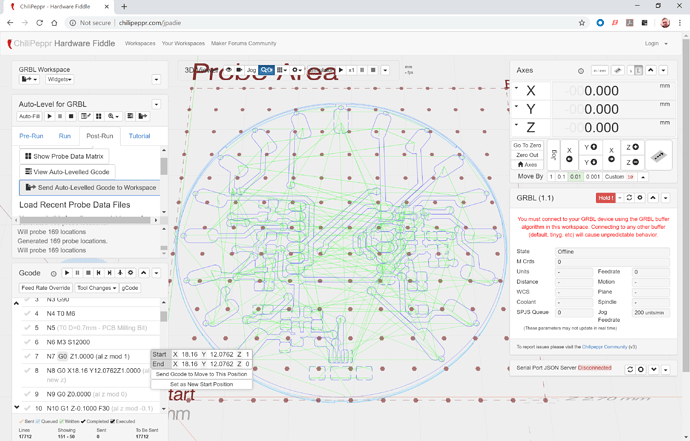

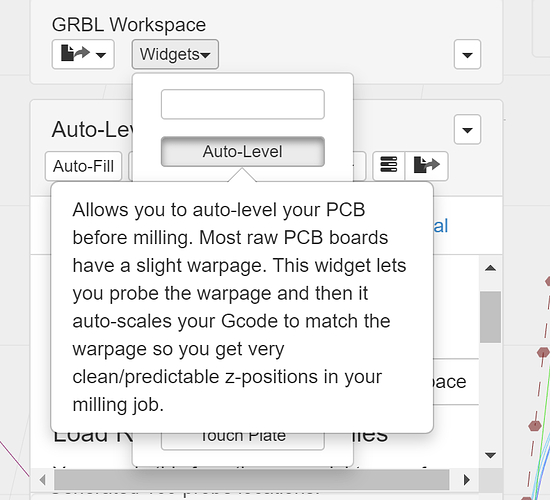

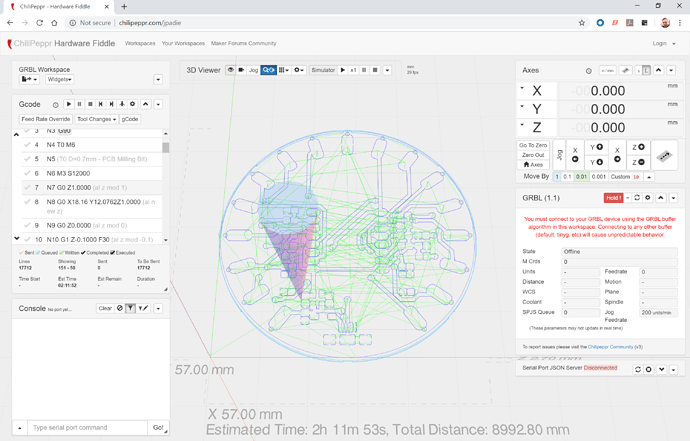

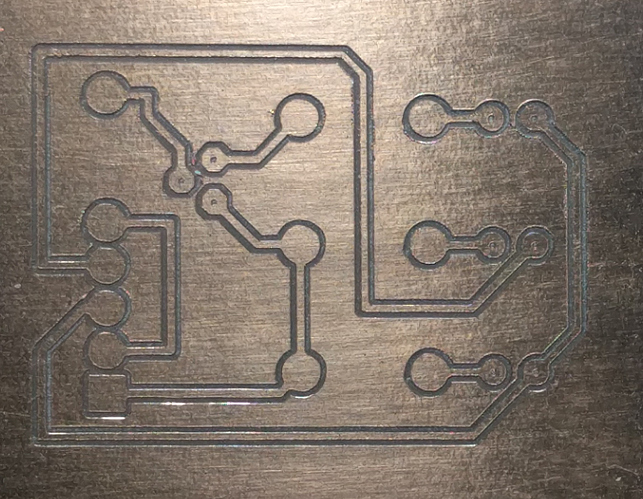

The Chilipeppr interface offers great ideas, and I was expecting to spend a couple of days using it and learning the best ways to run it. The import of Eagle files, with graphics indicating the import has worked and producing the outlines of the PCB tracks correctly, looked really good. Adding to that, Auto Levelling with probing that revealed the undulations of the underlying PCB in a neat graphics display was very inspiring.

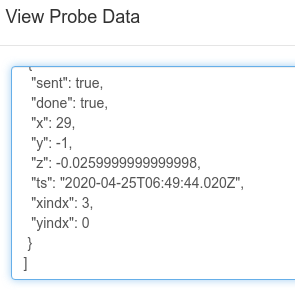

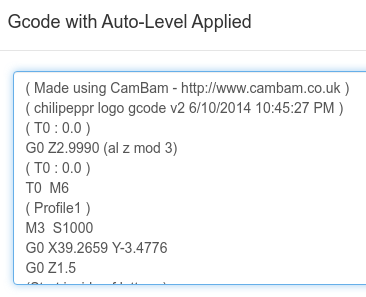

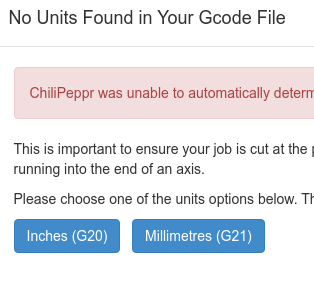

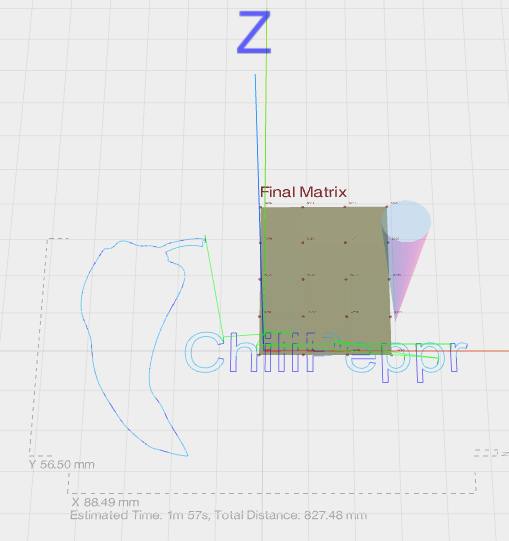

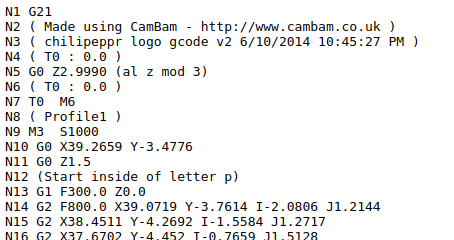

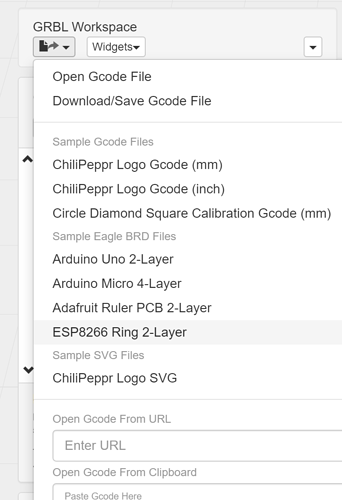

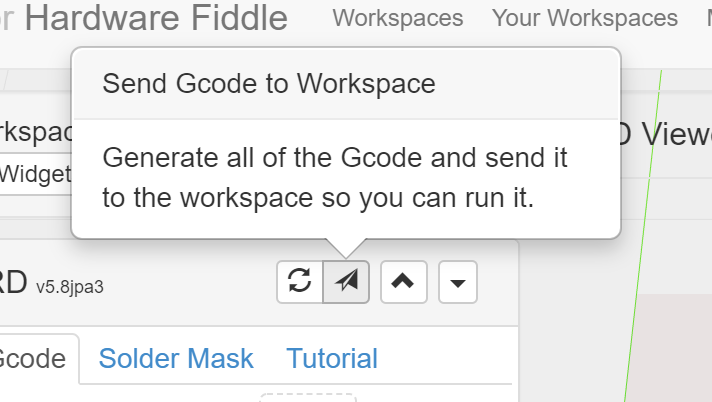

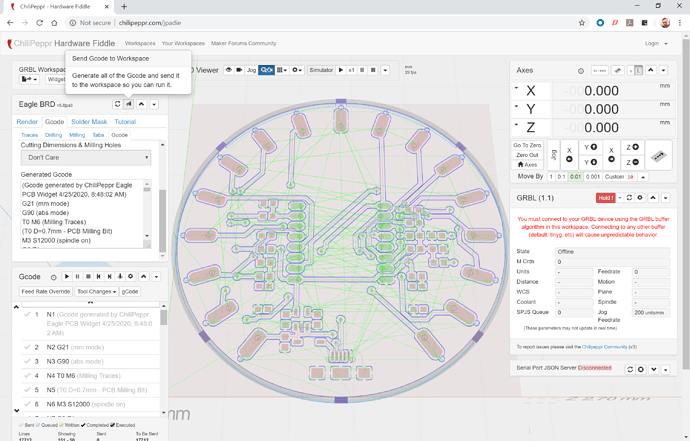

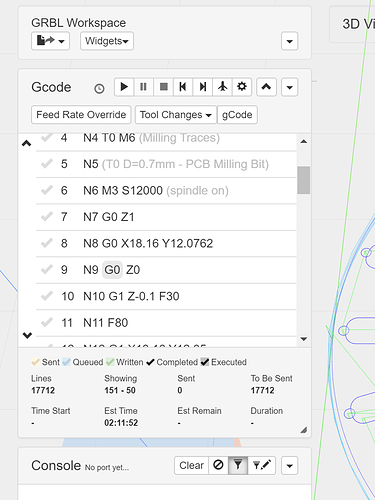

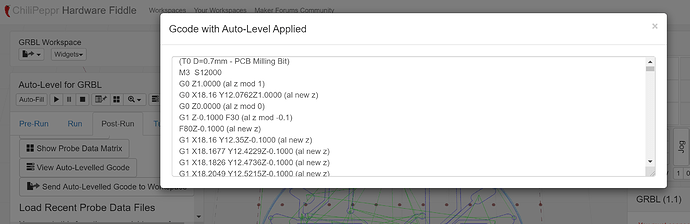

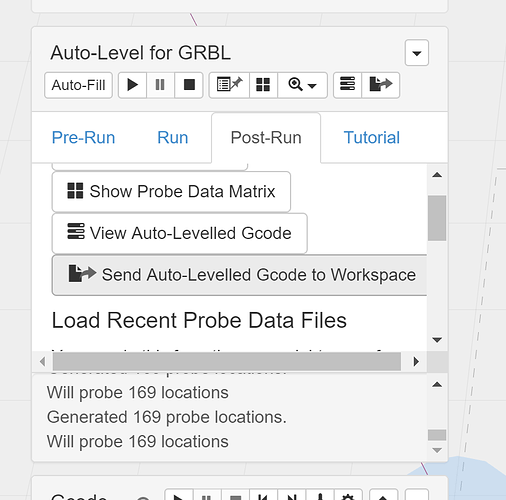

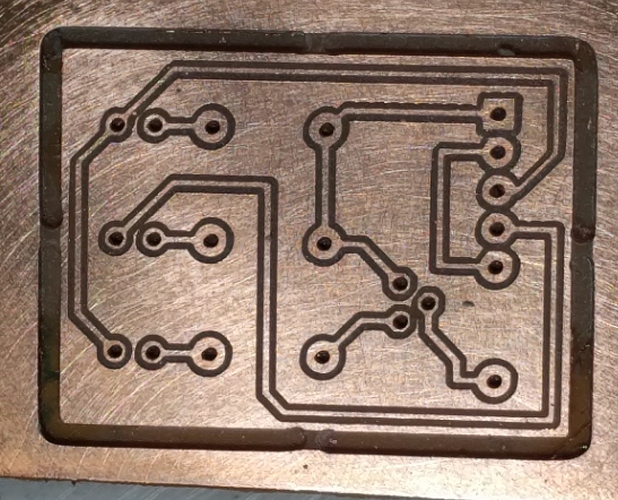

After 6 days of intensive work, I am still at a loss as to what is the best sequence to enter basic numbers to get a PCB engraved. I have just hit the reset button on a job that had my Eagle PCB on the screen, homed, gone to start of PCB, set to zeroes, Auto Levelled with probe, I went through and checked each tab and made what I felt were sensible choices on the Eagle import. Exported the “Levelled GCode” I could see in the preview “to the workspace”, and hit the GCode run button, and what do I get? Not my PCB, but somehow the ChiliPeppr demo logo thingy is still in there somewhere and it has started to engraved that instead.

I am at a loss as to how Javascript, and in turn CP keeps track of what file it is using and how to anticipate what it is going to do. So far I have only had one engraving that actually used the Auto Levelling, though I have tried to set it up many times. Every time I go to check the G-Code tab, the CP Logo returns. How does it store settings? Some of my choices seem to carry over for a while then unexpectedly they revert back to the defaults?

One of the vouched advantages of Javascript is the Event based Programming. This all very well to cater for users who skim around trivial web pages and click on almost randomly connected data sets. However for me, trying to set a complicated, time consuming job methodically it is driving me mad. Everything works, no errors, but very little seems to work predictably together, the import, the levelling, the G-Code sender are so independent that they just don’t make sense or establish any hierarchy of control or decision making strategy.

Please forgive me if I have missed something critical, and I don’t intend to give up easily, but is there somewhere a straightforward explanation as to how to manage the workflow between these widgets successfully.

For example, just one question amongst many, should I always import the Eagle board before Auto Levelling probing, or the other way around? Which one? If there is a joe-bloggs everyday user out there who can help me I would be very grateful.

Success seems tantalisingly close, but I am yet to experience it.

RobW