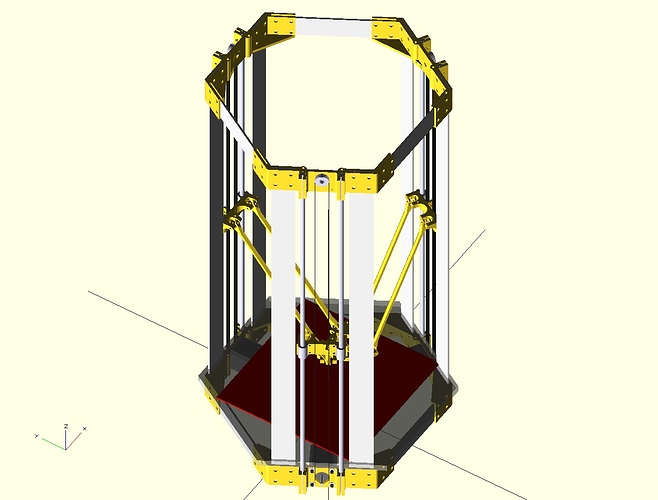

I’ve been looking a the delta designs (rostock, kossel, cerberus, etc.) and love the concept for the simplicity, reduced part count, and aesthetics. I like the design of the kossel (using aluminum extrusion) framing but am concerned with the wear of running a on the extrusion (which is not designed for such use). On to of that, extrusions can be a pain to source locally. I’m leaning toward the original rod/linear bearing carriage design, but find the structure of the rostock (needing the large brace for structural stability and torsional stiffness) is not that elegant. I’ve been brainstorming some alternatives that use rods for the carriage, but don’t rely on the rods for structure, and have come up with this variant I’ve tentatively called “flatstock” giving a nod to the rostock parentage, that used flat barstock aluminum (1.5" x 1/8") that is readily available locally.My thinking is that the pairs of flatstock bolted into the printed frame should give the rigidity I’ve been looking for.

Not sure if this is worth pursuing, however, as I think it is a bit over-designed and compromising, with some risk of the large printed pieces flexing too much to provide the stability I was hoping for…