So several years ago, when I got my K40, I considered my options for an air source for my air assist. The 3 real options for running an air assist are:

- Conventional air compressor

- Aquarium pump

- Airbrush pump

My K40 resides in my home office so I wasn’t going to be able to tolerate a loud pancake type air compressor and I really didn’t want to try and plumb in my shop compressor. That left me with either an aquarium pump or an airbrush pump. I opted for an airbrush pump mainly because I figured I could use it to airbrush if I wanted to.

I have mine running into a 5 gal portable air tank to give a smooth flow and I regulate the flow with a LZQ-5 flowmeter. The pump can produce about 20 L/min but I typically run 10 L/min for most things using a Light Objects type air assist head. The main downside to using an airbrush compressor, for running an air assist, is that they are not typically designed for periods of long continuous use. To keep the pump head from overheating, and prematurely failing, I’ve had a small 4" AC desk fan balanced on top of the pump head to help it cool faster.

The fan cage rattles a bit on top of the pump when it’s running but, all in all, the pump has worked just fine for the past 4 years. However, the small cheap fan I had been using finally gave out and I needed a new fan.

The pump sits on the floor in front of the laser because I’ve had some issues with vibrations from the pump affecting the engraving quality. The pump tends to wander around a bit on my hardwood floor so I decided it was time to build a base to contain the pump and also integrate a mount for a new fan.

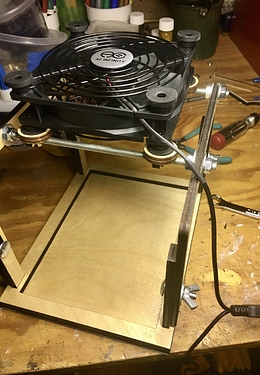

For a new fan, I opted for a quiet 5V 120mm computer type fan that does 52 cfm.

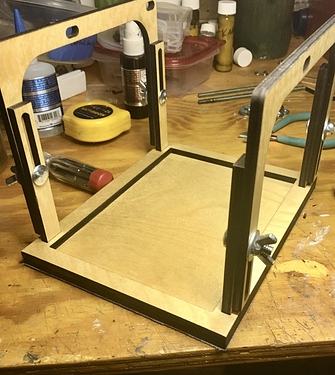

For the base stand for the pump I designed and cut a 2 piece base from 1/4" ply. It forms a tray that the pump sits in so it doesn’t wander off. As part of the fan integration I cut two part sides from 1/4" ply, that slot into the base, and made them height adjustable with slots and carriage bolts with wing nuts. This will allow me to control the fan height and make it easier to get the pump in and out with the fan supports installed.

I used some spray glue to cover the bottom of the base with an old rubber mouse pad that I had been apparently saving for just such a project. This will help keep the base from wandering around with the pump.

For the rest of the fan mount I cut some discs with a raised rim, basically a small cup, form 1/8" ply that the rubber foot pads of the fan will sit into. These were attached to pieces of 1/4" all thread with brackets cut from 1/4" plywood and some screws.

The all thread and foot pads are mounted between the sides with nuts and washers to suspend the fan above the pump head.

Then just raised the sides up, slid the pump in and then lowered the sides back down. Works great, no more fan rattle and no more wandering pump.