Alright time for me to join the discussion. Ill get used to the website style quickly, although its no google plus, haha.

Here is the idea I proposed to Nick and Daniel at MRRF. I hope to reiterate and make clear what I was trying to express in words at the event. I think it has a lot of potential, while being not terribly difficult to implement.

https://kayserworks.com/#/fiberbots/

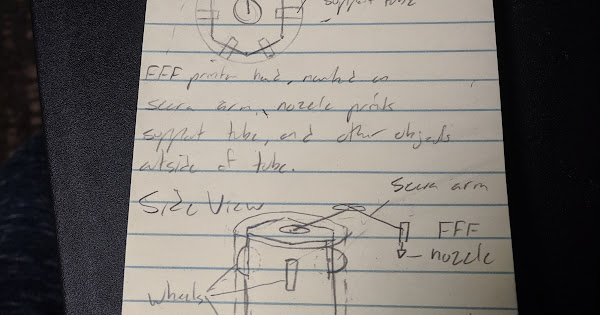

This is the basis for my idea. Like the fiberbot, this printer will use a tube to keep supporting itself in the z axis, climbing up it, and adding to it to make it taller. outside of the tube, the printer can produce whatever useful object that is desired.

Here is a drawing

Tell me if i need to redraw or eleborate on some concepts.

I like the tube system, because it is simpler, and more stiff than multiple smaller tubes, and it less prone to failure.

1 Like

I meant to post this a while ago, but just got around to drawing it out, I see Ryan has since mentioned a very similar idea.

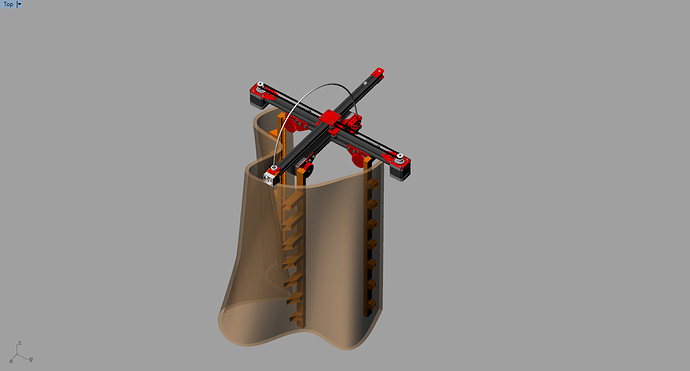

i saw that fiber bot some time back and was also thinking on a climbing bot. I thing the problem with the tube will be that like the fiber bot it will be hard to keep a vertical alignment. Another possible approach could be to embed herringbone tracks in the model itself and use them to climb on . The tracks could be designed as break away ones and could be trimmed later with a shears or a saw.

good idea, I think that would help more with grip, rather than alignment. I’m no coding expert, so I don’t know how this could be done, but i was thinking some sort of gyroscope sensor could be implemented into the firmware to keep the robot perpendicular to the ground.

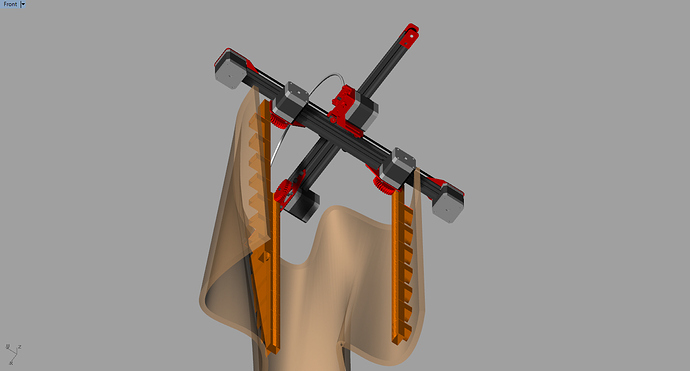

this are my thoughts put down just for clarification . the print starts with a preprinted frame and then it climbs up by printing a sacrificial rake. I don’t know how plausible this is.

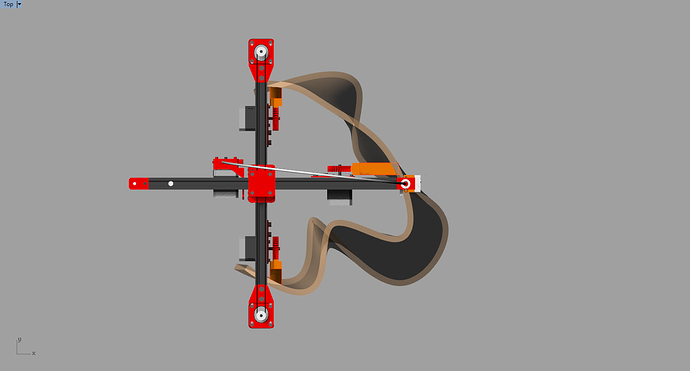

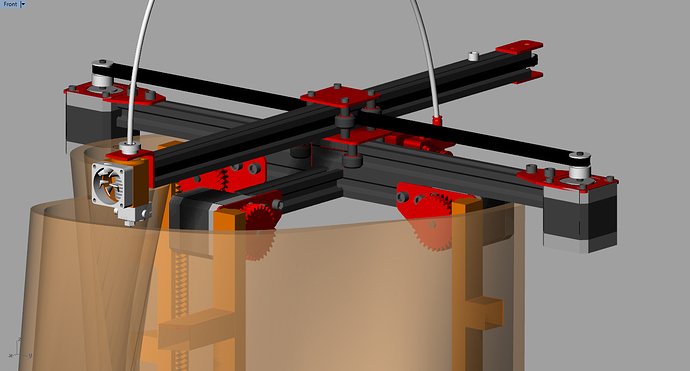

Well, it won’t work as pictured, because the nozzle can’t reach the edges of the print, but that could be fixed by setting the pinions further out from the crossbeam. For balance reasons, I would probably also put the motors on the front side of the pinions, since the whole mechanism looks kinda back-heavy. Maybe even lose the bowden tube to get the extruder motor’s mass further forward as well.

I also don’t think the rectilinear supports connecting the racks to the outer surface will be stiff enough, especially considering that you are presumably planning to print them in vase mode. It’s also a lot of unnecessary bridging when a thin full-length connection would be easier. Using something like Scherk’s second surface might work even better, because the compound curvature should make a much stiffer structure while also being much more interesting to look at.

Of course, you’re still dependent on the stiffness of your outer shell to keep the spacing of the racks consistent. If it flexes under the weight of the printer, the racks will move apart, allowing the pinions to slip down and the nozzle to crash. You wouldn’t even have to jump a full tooth for this to be a showstopper. Adding flanges to the sides of the racks with wheels that wrap around to grip the rack should solve this problem.

1 Like

BTW, a polar/SCARA arrangement would probably work better for X/Y in this case, and could even allow you to completely encircle your racks. You probably still couldn’t do a single continuous perimeter around it without slip rings and some other accommodations for >360-degree rotation, but if you could get it to rotate far enough to overlap the ends, that would be really cool.

It also occurs to me that all of these ideas that require a starter piece might be able to print them themselves if they had an alternate short-distance Z axis, maybe similar to the one on the Helios. You’d probably have to manually transition it onto that piece once it’s printed, but it saves you from needing a separate machine large enough to print that starter piece…

If you wanted a ridiculous length of bed without having one, you could have a printer that uses a roll of paper and unrolls it in front of the printer. It would print on that paper which would be laying on the floor. I do not know how well this concept will work the various ideas here, but I figured I would bring it up. I worked at a place that did printing. The paper rolls could literally kill a person with their weight. I imagine you would be using rolls of paper that would not require a forklift to move.

thanks for your great feedback. Yes i will move the motors out of the way in the x axis… that was a bummer. Flipping the z motor direction and adding flanges is a great idea. I am not so sure of adding a direct extruder to balance the weight but a lightweight titan with a e3d super volcano might be a better approach. I am not looking at printing in vase mode, but printing 10-15 mm thick single surfaces . so the racks could be made to work with more arch like bridges.

I thought of using a scara arm for the x-y but for now i let go of a polar/scara approach because my past experience with their calibration and flex was not good.

I was actually looking for your half corexy you had once shown on g-plus but now it has gone missing. That mechanism might be better than having the y axis arm swing back and forth .

thanks again.

You mean “core-T”? The design is pretty simple, just two stacked T-shaped belt loops. The trick (which is hard to see in pictures and videos) is that the belt attachments have to be on opposite sides of the cantilevered pulley. Then it just drives like CoreXY. Here’s a video of someone else’s implementation: https://www.youtube.com/watch?v=6EtJfaiQ9H0

yes thanks i was looking for this only. are there any drawbacks to this mechanism?

It should have a CoreXY’s resistance to racking. It’s a cantilever though, so the rigidity is going to be highly dependent on the bearings you use. That said, with the right bearings in the right arrangement, and a cantilever that’s not too long for them, I think it might be even better than a standard CoreXY, because it makes it possible to use an exact-constraint solution, which you can’t do with a standard CoreXY.