That’s the maximum throughput at zero pressure. The blower in an AD 350 draws up to 1100 W and goes up to 9600 Pa. It’s way more powerful. It can pull a lot more air through that filter stack.

The theoretical maximum throughput at zero pressure by itself doesn’t really mean much.

Sometimes they will also tell you the maximum pressure at zero throughput.

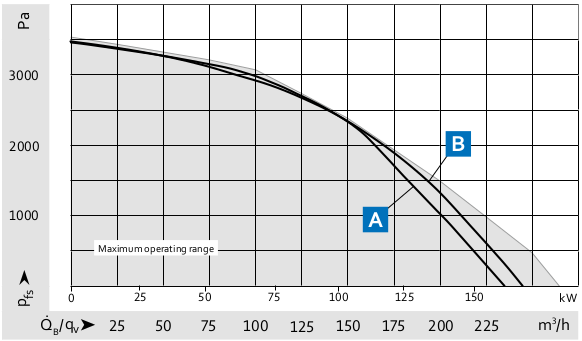

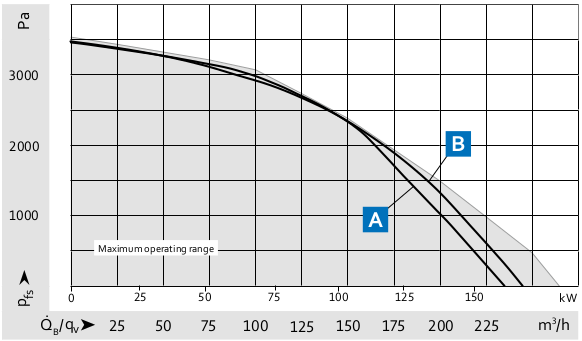

If you want the full picture, you need a pressure/throughput curve like this one:

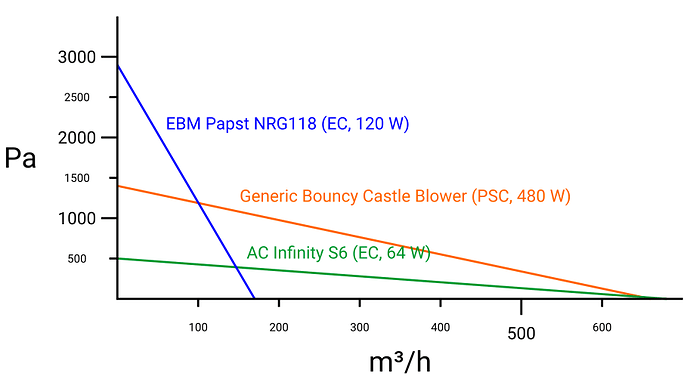

Here is a rough comparison between my old bouncy castle blower, my new Papst blower, and an AC Infinity S6 mixed-flow inline fan:

This is a bit simplified and only for illustration purposes. The actual curves are of course slightly bent upwards and not straight lines.

Anyhow, if the goal is to move at least 70 m³/h (which is what the stock fan of my K40 can move under ideal conditions), the quieter Papst blower would actually outperform the much beefier bouncy castle blower.

And there is another factor to consider: The pressure drop across filters drastically increases if you pull more air through them.

E.g. if the pressure drop across everything is 1000 Pa at 110 m³/h with the Papst blower, then the bouncy castle blower would not be able to move 200 m³/h as that graph suggests since the pressure drop would be significantly higher at that higher flow rate.

If you need more throughput, the best option are larger filters with more surface area. If you got twice the area, you can move twice as much air at a similar pressure level.

If you want to build a filtration unit for a specific existing machine, I recommend to measure the actual throughput (a sub $10 anemometer is fine for this) to figure out what kind of minimum and desired throughput you’re actually looking for. Then you’ll know which range of a pressure/throughput graph is relevant to you.

Well, it’s a pretty complicated topic and it gets more complicated if you add differential pressure sensors, VOC sensors, flow rate sensors, automatic flow control, a basic remote interface, and whatever. There are more caveats with all of those things.

Anyhow, recirculating the air a couple of times is already a bit hairy with better commercial units. Filtration isn’t perfect. Most VOC sensors are pretty crude and not super reliable. Most units do not monitor the CO levels in the room. You definitely need at least some ventilation.