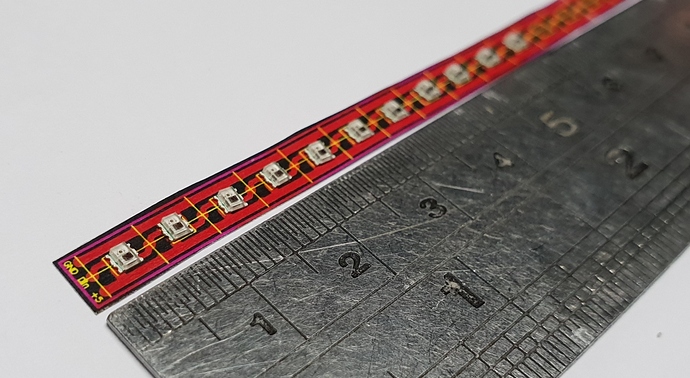

Im sure some of you may seen these new WS2812 2020 Pixels http://www.world-semi.com/DownLoadFile/139 I have been trying for the last several months to get a big company to fab these, but no one is really biting. So i decided to take matters into my own hands. I started a Kickstarter today https://kickstarter.com/projects/elecdashtron/ws2812-2020-addressable-led-pixel-strips to raise a tiny bit of cash to develop and fab these. I’m aiming to make these very specifically for low power wearable use. Hope you all don’t see this as spam, please let me know if you do ill take the post down

@Leon_Yuhanov You’re a regular member here and I would hardly consider this spam.  This looks like a excellent endeavor, because sometimes you have make something happen yourself if you want it. Best of luck in getting this funded!

This looks like a excellent endeavor, because sometimes you have make something happen yourself if you want it. Best of luck in getting this funded!

One thought, if you’re getting these flex strips custom made, why not make the solder pads bigger for easier soldering? (Assuming this is actually possible. I know it’s small!)

I’d love to see that strip (not just the pixels) in comparison to maybe the 90/m 2012 strips…what we can barely work with since the pads are so small…maybe if the pads came thru to the rear? (I know then that limits mounting, but a layer of foam tape would insulate)

How hard would it be to cut and resolder these? I already work with 3535 7mm wide strips for wearables, cutting and resoldering to make irregular shapes and although I really want smaller, I’m not sure how I would manage to resolder them. Would I need finer tip and a microscope?

Good luck with the Kickstarter! I don’t imagine anyone around here would see one on-topic post from a regular contributor as spam.

I don’t really need high-density strips, but I’m in, just to see what you can pull off! If you add a pledge level with the source code for one of your fancy patterns/animations, I’m definitely in for more.

I agree with @marmil , I know you’re size constrained, but the larger those pads are the better.

Count me as a backer, buddy! Good luck!

I’ve always stuck to the 60/m strips because they seem to be the cheapest per pixel/area of coverage (and they’re easier to work with than the 144s), but I love all the stuff you do with higher density and smaller pixels.

Oh, and you might want to add pics and video of the amazing masks you make to that Kickstarter page. Show the people what you plan to do with them!

just backed you. good luck

@marmil Im going to get a few different designs fabed. The one up there is 5mm wide. I have one that is 4mm wide with square large pads that go @Michael_Sime through hole to the other side. The 4mm strip is double sided, bottom layer is GND & +5v with each hole coming up to the top layer. @Franck_Marcotte they will ABSOLUTELY be cutable at each point, thats one of the main goals!

@Leon_Yuhanov This is totally not spam, especially if you make some 32x16 or 32x32 matrices, in which case it’s really really not spam

But as feedback, non flexible strips are not very helpful to any of my projects. Your build also looks like way too much space between the pixels. It looks like you could fit 3, maybe 4 by cm. The reason to get something that small is to have a very high density.

@Marc_MERLIN Hey Marc, once I can fabricate these I will 9000% start making matricies  Re flex, these WILL be flexible(i also have 0 use for rigid strips). RE your assumption that more can fit it, I highly welcome you to try yourself and shoot the Gerber across. Ill be super happy for anyone contributions to this project and will fab up your version as part of the KS Campaign 1st prototype round(if it happens)

Re flex, these WILL be flexible(i also have 0 use for rigid strips). RE your assumption that more can fit it, I highly welcome you to try yourself and shoot the Gerber across. Ill be super happy for anyone contributions to this project and will fab up your version as part of the KS Campaign 1st prototype round(if it happens)

@Leon_Yuhanov could we see a side-by-side comparison to 60/90/144 existing strips I know personally I need visual aids, as I have no imagination whatsoever

@Leon_Yuhanov I’ll take those 9000% odds  For hardware design, it is indeed something I know nothing about, so while it looked like at least 3 LEDs could fit per cm (4 would be a stretch), if the router says it doesn’t work, I’ll take your word for it.

For hardware design, it is indeed something I know nothing about, so while it looked like at least 3 LEDs could fit per cm (4 would be a stretch), if the router says it doesn’t work, I’ll take your word for it.

And for flexible panels, you’ve likely seen my shirt which only has 24x32 pixels with a 1cm pitch. While people think it’s cool, the geek in me is ashamed of the low pixel density and I’m held back on sprites by the number of pixels. A 0.5mm pitch would indeed be awesome.

@Leon_Yuhanov for pixel density on a matrix, look a this product (sadly not for sale anymore): https://www.tindie.com/products/robogeek78/flexible-led-array-32x32-ws2812-ws2813/

It was a 7mm pitch.

With your LEDs, you can of course cram a lot more within that same footprint, but I’d still be ecstatic with 4 pixels per cm^2

Also, for big matrices, does it make sense to use WS2813 instead? One thing I found is that they use a lot less power when they’re not on, and of course they provide that backup path if they do burn.

But that also means one more trace for you to worry about, as well as pixels that may not be as small, yet.

@Marc_MERLIN I think to make really large matrices with these WS2812 2020 pixels, things MAY start falling over after 32 x 32…For now i wont say more as there are way to many unknowns and variables

@Leon_Yuhanov yeah, saw that, I was more interested in the final spacing on the strip you’re proposing…do you have a photo showing your prototype with the spacing you’re thinking next to an existing strip?