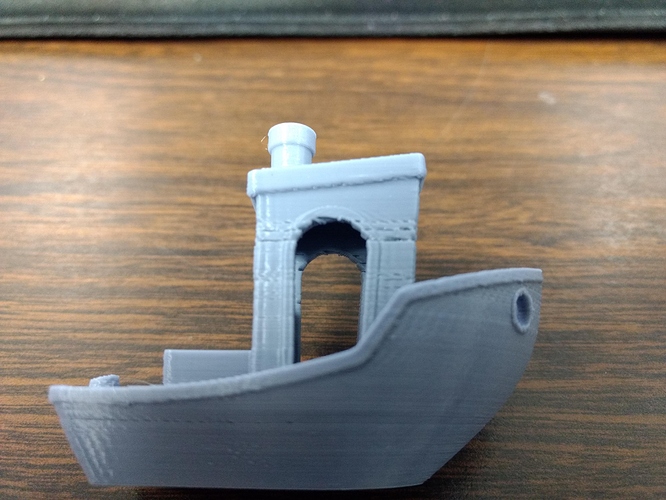

I’m having consistent issues on certain layers of all of my prints. I’ve never done troubleshooting for the Z-axis or related items before so I’m looking for a ideas from the hive mind. The Z-axis motor? The rod? Or maybe it’s an extruder issue? I’m stumped.

This is a CR-10, with a brand new replacement extruder, nozzle, etc. Installed it last week but the printing woes continue. I’ve tried upping the flow rate and that helps sometimes, but I’m still seeing issues.

it looks fine to me @Kyle_Taylor

Have you re-calibrated after the install? Have you printed a calibration object?

To me that looks like lost steps on extrusion. Does upping the extruder temp help? Have you double checked the step driver voltage for your specific drivers? If the voltage is too low it can result in this problem too.

Would it help to print 2 Benchy’s on different parts of the bed? If the errors occur at the same Z heights then I would suspect something mechanical. If you get similar problems but at different heights then maybe you are losing steps at the extruder due a wiring issue where it can’t carry sufficient current when in certain positions.

Looks to me like you’re losing some extrusion volume after repeated retractions. Could be a minor jamming issue or a coast/retract setting type issue.

@Greg_Copeland No I have not checked the voltage. @Joe_Morrison I will try a couple on different parts of the bed, but I’m leaning towards mechanical as well. It used to print so nicely last year

Help me understand why you think it’s a Z axis issue and not an extrusion issue? Is it coming out too tall or too short?

@Ryan_Carlyle Mostly because it seems to happen on layers so perhaps it was a wobble, a bent rod, something mechanical about the height. But my initial thought was my extruder is cruddy and I’m thinking of replacing it, but I wanted more feedback. Which is why I’m glad for any ideas.

Have you tried different prints to see if it’s always on the same height? This would rule out retraction or other issues.

Suggest printing a 2-3 wall box (no roofs or infill) to see if it has similar issues.

What kind of extruder? If it’s PTFE, swap the tube. If it’s all-metal, do some nylon cold pulls to check for crud.

Ryan is right. It could be crud too.

Forgot to mention in addition to the new nozzle and hotend it’s new Capricorn PTFE tubing, new connectors on both ends of the tube. All less than a week old. The extruder and all of its bits are over a year old now.

@Kyle_Taylor heat break is the most important bit if it’s all-metal like an E3D. Could disassemble and look down the inside for crud

@Kyle_Taylor This looks like an extrusion problem to me. I would suggest a cold pull to clear the hot end of any gunk and then check your retraction settings. You may need to increase the amount of material re-primed after a retraction. It seems like you have issues where you’re having more retractions.

It does look like an extrusion issue. What are your retraction settings?

@Joe_Morrison printed 2 in opposite corners… Same exact results. @Ryan_Carlyle is on the trail! I reduced my retraction from 10mm to 4mm and my z-hop from 1mm to 0.5mm and saw significant improvement. The one on the left is one of my “opposite corner” tests with no improvement, and the right side is the latest with reduced retraction. Looks like I need to run more speed and retraction options! I’ve got some ghosting to deal with also. Looks like I’m on the right track though. Thanks for the all of the feedback. I really appreciate it!

Edit, reposting photo:

missing/deleted image from Google+

@Kyle_Taylor 10mm?! Why?! That’s just asking for a jam. But I’m glad to see you’re on the right track. Getting the settings dialed in can be a pain for sure. Make sure to check settings like “extra prime amount” and “coasting”. Another thing I do is physically watch the filament come out of the nozzle with a flashlight. you can see how much is coming out and if you have enough or even too much.

would assume these retracts (length) grind the filament so traction is reduced. In Cura you can limit the retraction upon extrusion length to counter this “maximum retraction count” also “minimum extrusion window” and “retraction minimum travel” to limit retraction in a small area.

@Kevin_Danger_Powers I was going off of a profile from one of the original models from my machine. The “cat” gcode.

And I tried a 2mm retraction last night after my last post and got a LOT of stringing. So I’m going to Keep my z-hop settings and try a couple more retraction variants to see where the sweet spot is. Then I’m going to work on the speeds.