@SirGeekALot replacing the tubing should be straight forward. The glass has barbed fittings so just slide it on all the way and it should be good to go. Make sure to give yourself plenty of extra length so you can easily tip the machine to remove the air bubbles.

I happen to live near Lightobject so one day when I was there I picked up their tubing.

http://www.lightobject.com/5X8-Silicon-Flex-Tube-for-Air-Assistance-or-Water-Cooling-P776.aspx

I also added these tie wraps. Don’t over tighten. just firm is good enough.

@SirGeekALot : as Ned Hill pointed out is is probably mineral deposits, but I noticed that my silicone tubes are getting blunt(er) even after cleaning with acid, so there could also be residues from that cheap china tubes.

Best solution: replace with higher grade materials: silicone or ptfe/teflon

Silicone should be cheap and sufficient for our sweet K40 needs.

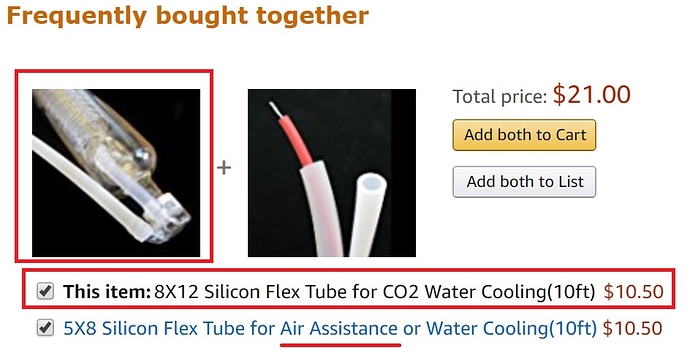

@Sebastian_C Agreed. As I noted above, I already bought 10 feet of silicone tubing from LightObject on their Amazon store:

James, Call them today (or monday morning) at 1-916-572-6080. You posted you got 8X12mm. That is the wrong size. You need 5X8mm for a K40.

@Steve_Clark I received it Jan. 17th. I’ll check the diameter soon (probably Sunday) and if it is incorrect, I think I still have time to return it via Amazon (I hope). Thanks.

@SirGeekALot YOU ARE CORRECT … I was wrong… I should have double checked on my old invoice .

"

8X12 Silicon Flex Tube for CO2 Water Cooling

LSR-WTUBE8X12 $0.85 16 $13.60"

Actually, it looks like the new tubing is too large (I compared it to the existing tubing). Moot point though. I decided to just use the existing tubing and it is working fine. I’ve already done my test burns and aligned the beam. I just need to do a ramp test and make sure I’ve got the focus where it needs to be, then I’ll be ready to actually try cutting a real project!

When you say it’s too large… is that because it goes on with only a very little stretching?

Mine was like that. It does expand a very little but just feels not trustworthy. That is why I used the tie wraps, just to snug it up a bit. I have no leaks or tubing popping off problems.

I didn’t even try. I wanted to make sure the darn thing works before I go mucking around and break it! The good news is, it works. I’ve already successfully done a vector engrave and raster engrave. I tried to do a vector cut, but it didn’t really cut though the thin cardboard—it just burned it a bit—even at 80% power. I haven’t determined the focus point yet, so no big deal. I’m happy!!