I see Mark Miller has finally jumped into the 3d printing pool. Here is a look at his mini lathe made with printed parts.

Very Nice Mark.

Originally shared by Mark Miller

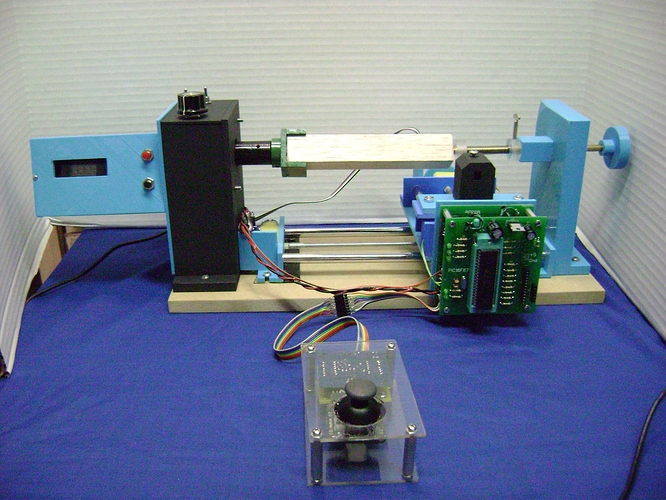

3D printed CNC mini lathe

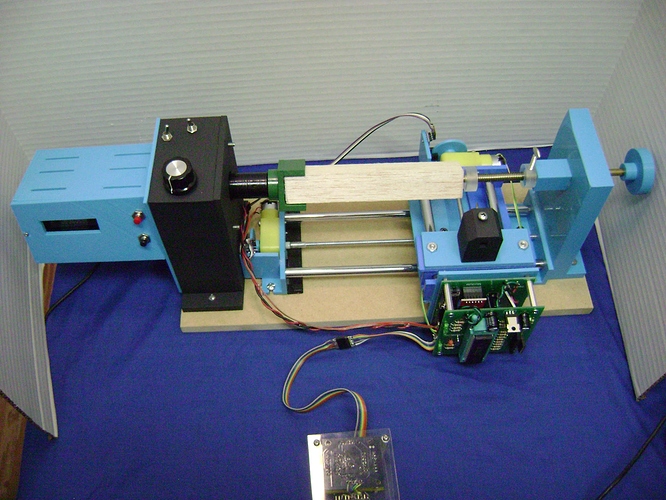

I got this finished and tested. I have built multiple versions of this(see my profile page) but his one is unique as I printed the parts from ABS. It takes about 24 hours to print all the beefy thick parts, but it was necessary to insure rigidity and make it lasting.

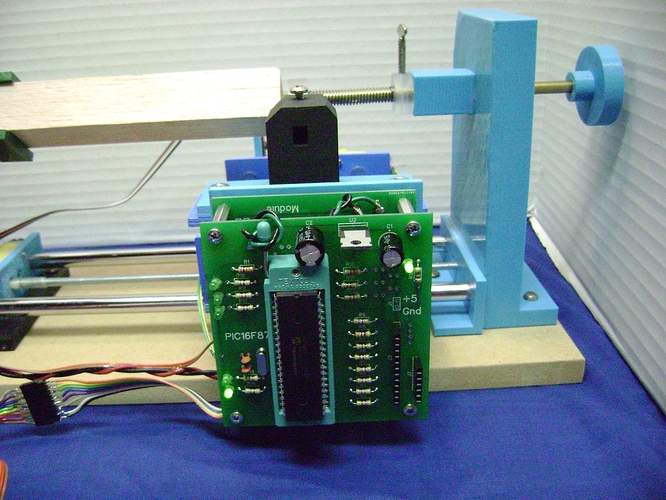

As in previous versions, there are no manual handwheels as the X and Y axis are driven from a PS2 joystick or from the programmed PIC chip.

The joystick can also act as a teach pendent and the moves are recorded and can be played back to create multiples of a part.

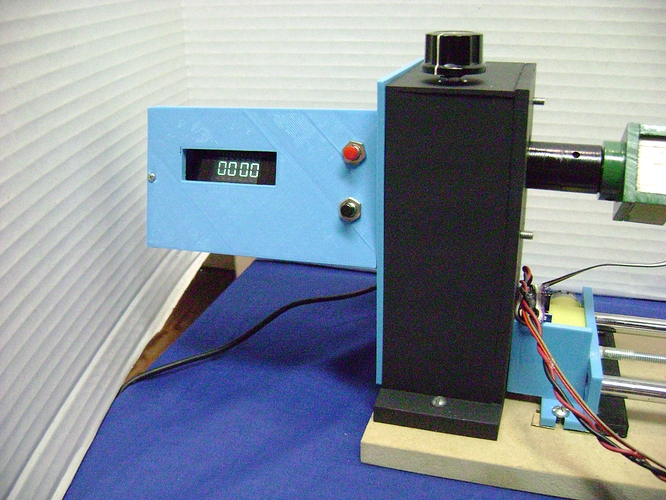

The DRO to the left keeps track of position of both axis.

This is a nice compact design, lightweight and highly mobile.

It can turn balsa, pine and other soft woods(I did some poplar also , but hardwoods might be too harsh unless very light cuts were made.

I made these to make aircraft and model parts from balsa stock, but have found them handy for other things such as knobs, pins etc.

No tools are required to change stock. The spindle motor is a brushless DC motor with RPMs from 1100 to 2400.

The ABS prints are inexpensive, but a bit time consuming!