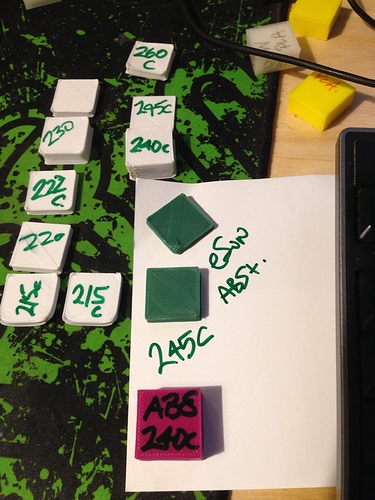

I need some help with eSUN’s ABS+ please. So I have been trying to get it to print and simply failing. As a control the purple is std ABS noname and prints perfectly at 240C, no fan, 100c bed. Both the white and Green ABS+ however I cant find a temperature it will print at, yet its supposed to be “better” than ABS. 215C up to 260C in 2 ~5C increments and the corners curl badly. Ive also tried 85~110C bed. The 2 green ABS+ were without fan and 30% fan as the top corner curling suggested too hot from googling. I have reduced the flow to 95% before any of these pictures were taken which seems to be ball park. I have an enclosure on the wanhao D6, it has a microswiss hotend mod. It prints everything else very acceptably Wanhao Red, green, white ABS all fine. Wanhao PLA, eSun PLA+, PETG, protopasta HTPLA, all great. So I am stumped rght now.

PLA prints…

missing/deleted image from Google+

just printed a protopasta smoky silver HTPLA replacement hinge so mechanically I dont see an issue.

missing/deleted image from Google+

What’s the room temp? Cool? Do you have an enclosure? MY printer is in the garage where it is too cool right now … I have this same problem with ASA filament.

(let me know if you find a way)

Oh and after the wanhao D6 mainbaord died and wanhao walked away from the warrante I fitted a duetwifi board.

Also on glass with cheap hairspray holds very well til its cold.

Yes, curling is too hot and requires a fan, but you’ve tried that already… Hmm.

Curling in ABS is cooling too quickly. Build a foam board box for the printer.

Thanks, It already has an enclosure. I added a silicon boot to the hotend, i might try and take it off. Maybe the radiant heat from it is enough to matter…hmmm

removing boot, no change.

New Zealand, nice day, summer.

try using cooling as with the pla … I always use cooling with abs (for now I only printed Esun abs)

Each material will behave a little differently. Settings that work on one may not produce good results on a similar one.

Another possible trick is adjusting your bed temperatures. Start out hot above the glass temperature of the material you are printing with to get the material to stick to the bed. (a tightly leveled bed is good here with a .2mm first layer) Then, after 3 layers or .5mm which ever comes first, drop the bed temp below the glass temperature of the plastic to get it to set. Don’t go so cold that it cracks off the bed. With it set it will have less tendency to curl as upper layers cool more. Your enclosure should keep it at a more even temperature to avoid stress cracks on the layers.

Blast the fan at 100%. It’s too hot.

In the past I tried a fan on ABS, 20~50% as some people reported better results and the result was always worse as some other people reported, LOL. I tried 30% part fan at 240C and no change, but I will try 50, 70 and 100% at 245C as “ABS+” is not “ABS” (maybe more than is realised?) @Francis_Lee In terms of “too hot” yes it looked that way if it was PLA but I went down to 215C and the curling and lifting off the bed was massive, the curling was less at 240C+ but I will try it without an enclosure also. I will also try 270C as 260C looked like 240C. Kind of surprised since this eSun ABS+ been out a while that so few have tried it. @Nathan_Walkner , good idea I was wondering on that though Ive had perfect ABS 20mm blocks. I find the 20mm blocks get me ball park for especially flow and temp then tweaking as needed…this time.

I agree with the first layer said by @Nathan_Walkner . Top curling after the fact is usually excess heat, where the top layer is still soft, and at corners it’ll stick to the nozzle when it’s passing over and then curl up, like how people curl ribbons with a flat edge. After that the problem gets worse with each layer until that corner flattens itself out again.

It seems like maybe you have a bum batch of ABS+ because in comparison the Amazon reviews are incredibly favorable.

Also your 220C looks halfway decent… Can you reproduce that?

I have no issues with bed adhesion (not unless I am silly), its the curling later on that is an issue. So I find on glass for PLA 60C, PETG 90C and ABS 100C and a brim with cheap hairspray usually gets me perfect adhesion. Dropping 5c off those and yes sure I start to get curl, 10C and a lot of curl. Ive tried 105C and 110C also seems to be similar to 100C so Ive not gone higher, for ABS+ though 110C might be better. My thought is its cooling too fast so I might need a hotter/heated enclosure. I might try dropping the flow a bit more as well but I am down to 95%…

@Francis_Lee , yeah I thought 220C looked nicer as did 240~245C. I will have a go and redo 220C and also try 218C. 215C was terrible (85C bed and 110C bed) , 222C not as good which means a very tight control.

I wondered on a bad / poor roll. I have ABS+ in white and in Green both seem similar output but they both could be old. I have no idea how long they sat on the sellers shelf but he has only just started up selling eSun but it could have been a long time in a warehouse I suppose.