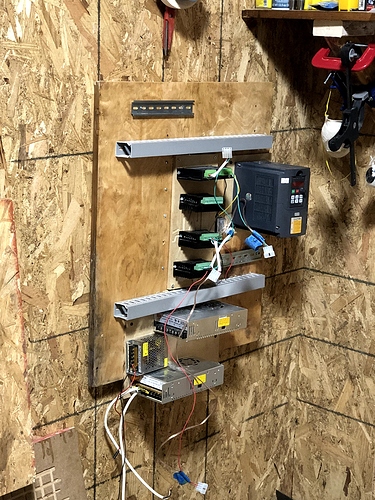

I’m trying to get somewhat organized by redoing my controller box. I felt that my pc enclosure was going to be too small and would not be able to include my VFD. I was also tired of having everything on the floor. It’s probably not the ideal, but I think it will work. I ordered some DIN terminal blocks to help organize some of the wiring.

I think this will make it easier to add and switch out my drivers when necessary.

It would take a good sized cabinet to fit all of that in it.

I used to have some noise issues, presumably between my VFD and the limit switch wiring. The wires for all of this was running too closely together, coupling VFD noise back into the motion control board. So when rebuilding my setup, I rerouted spindle power cable on the machine but also chose locate the VFD separately from the controls. VFD is stand alone now… Just mounted to the wall.

@Jay_Polo noise interference can be a serious issue with CNC. I ran into big problems when I made my first motor drives. One would run fine but when I tried to run two at once they’d interfere with each other. It took me a long time to figure out how to fix that. I ended up doing what I eventually learned most other drives do. I optically isolated the control lines of the drives. But figuring that out on my own took me a while. I also made some effort to make sure the BOB I designed wasn’t sensitive to noise. I used pull up resistors on the inputs that loaded it up somewhat. It takes a bit of current now to actually change the state. Finding out how much current a parallel port can supply is an impossible spec to find though. The best I could discover was that most can deliver at least 3ma. So I think I shot for 1ma? Which an electromagnetic noise signal is just not going to induce. So far so good.

Isn’t better use the drivers in the horizontal position?

Same for the power supply, the bottom one spread heat to the next, both spread heat to the drivers, okay, it’s open place but…

@Marcos_Duque_Cesar I guess I will see. I’ve seen some other setups similar to this though, with multiple PSUs enclosed and placed closer together than these. It’s my first controller set up…unless you count the two times I just had everything on the floor or on a table. I gotta hope this will be better than that. I think it will be less of a chance for wires to come loose or have something damage my controller board. I’ve already blown 2 TinyGs.

I’ve tried my best to think ahead about potential issues and make the table & machine as adaptable and adjustable as I can. One thing I’m really glad I did was to put casters on the bottom of the table. Otherwise, it would have been a real pain to move. As it is, moving the frame around (especially at one location) is no problem. And with the locks on the wheels there is no excessive movement as heavy as the machine is.

@George_Allen I am glad also that I have casters on my table however my table has a built in lift so it stays on the ground during operation and on the casters to move it.