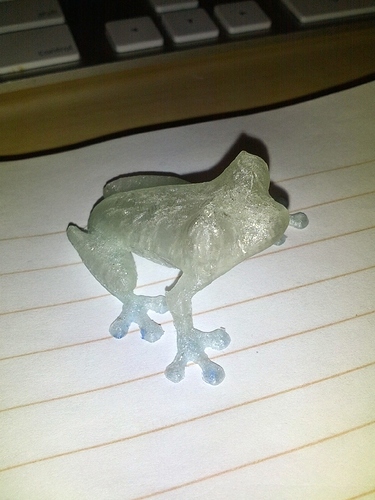

I have two rolls of PLA one blue and one clear. I kept having issues with a print failing after a few layers. tried lowering temp a few degrees, then going higher. ended up printing this at 250c according to the temp on the rep2x. The nozzle clogged however about 20 layers up, but i caught it kind of quick, cleared it and resumed, this was the result.

Anyone else having issues with PLA on the rep2x? I see there could be an issue with the default plunger feeder(got the parts on order to upgrade to spring), or the temp sensors, or even the PLA spools(which both blue and clear seem to act identical and from two diff manufactures so seems odd) I find it interesting I had almost zero issues with using ABS and PLA is supposed to be the flagship plastic for the cheaper rep 2, because they say ABS is the finicky one! Anywho, loving 3d printing regardless!