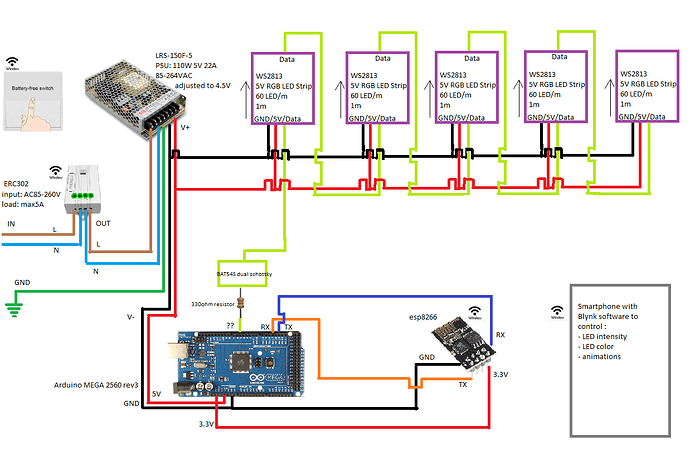

Hi! The schematic looks so far pretty decent. The current wiring of the strip looks a bit ambiguious, but the parallel topology is correct, it should work that way. On a first look using the 3,3V outlet of the arduino as supply for the ESP is an issue as the original arduino 2560 board is allowing 50 mA current drawn on that pin whereas ESP8266 type boards draw up to about 400 mA peak when using its rf transmitter. Usage of a proper low drop out voltage regulator is needed in that case, hooked directly to the 5V supply and to feed the ESP, for example an AMS1117 3.3V. Depending on your software skills direct programming of the ESP could be an option, as it is supported by the arduino IDE as well, in that case the arduino could be omitted in your setup. Another thing: When connecting different boards the logic levels, that are the voltage ranges on the lines that are outputted for respectively detected as a low or high correctly, must be matching. ESP8266 IO pins are 5V tolerant (not the supply voltage) but it must be assured that a HIGH from the ESP is detected as a HIGH on the input of the Arduino. That must be checked for all 4 combinations input/output and high/low level on both ends of the line. I have not really time to check that for you currently, so my tip for you is: always consider the datasheet that exists for mostly all compounds on the market (if not, dont buy it).

0 - seems correct, dont mix pos and neg

1 - ESP8266 is cheap and there is support and knowledge from the community. ESP8285 or ESP32 are alternatives. I am buying my ESPs at ali express, the delivery to germany usually takes about 20 days.

2 - Nope. 3,3V out on arduino is limited to 50 mA, see above. Use a proper LDO regulator, voltage dividers are definitely not working here.

3 - The logic levels need to match, see above. If the level limits do not match a proper shifting circuit must be used between the components. google “mosfet bidirectional level shifter” for examples

4 - depends on your setup, google for some example setups for a ESP8266

5 - (+5V)–|<|–(Data)–|<|–(GND)

The 330 ohm resistor’s secondary function is to limit current if one of the schottkys get conductive in order to prevent over/undervoltage. If data line is climbing over 5,3V the left diode will start to conduct limiting the rise of voltage.

6 - yep, no problem

7 - The data out pin must be defined in FastLED. Secondary functions are irrelevant anyways, as FastLED generates the control signal in software via bit-banging

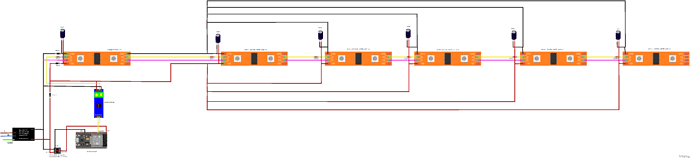

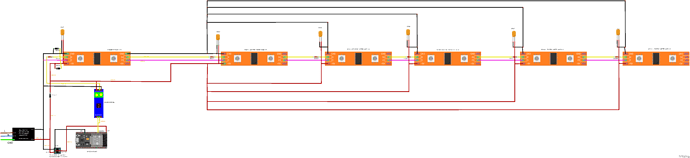

8 - AFAIR the second pair is for a redundant dataline. Both pairs are skipping every 2nd LED creating a interleaved chain. This is a feature of the WS2813 and enables strips to keep working even if a single LED went defective. But i am not sure -> consider datasheet and find an example schematic on google

9 - 10 gauge (AWG?) = 5 mm^2 -> drastic overkill  Use AWG 15 or 14. diameter of supply for the controllers is pretty much irrelevant, AWG24 should work as well.

Use AWG 15 or 14. diameter of supply for the controllers is pretty much irrelevant, AWG24 should work as well.

10 - Implement it in software. Why should there anything burn ? (Beside overloading the strip with current, but that you already took care of by using proper supply wire)

11 - ATMega2560 datasheet says: min 1,8V supply for max 4 Mhz, min 2,7V supply for max 8 Mhz, min 4,5V supply for max 16 Mhz. Manufacturer guarantees for these values, but most time 16 Mhz is possible at less than 4,5V supply

12 - Many digital circuits are taking damage if the voltage on input pins are going below the negative supply or exceeding the positive supply voltages. The input stages are not designed for these conditions, for example internal protecting diodes could turn into short circuits then, possibly melting your circuit or something ^^. External schottkys limit the exceeding of the input voltage on data pin to about +/-0,3V which is usually tolerable.

Some more issues:

If you dont like SMD components, use THT types. LDO regulators and schottky diodes are standard components.

Most linear regulators need external capacitors for stable operation, see datasheet for example.

The length of the dataline of WS2813 and similar types must not exceed 50 cm in length for error free data transmission. The 330 ohm resitor’s main purpose is to reduce signal overshooting which is increasing with line length. If you encounter problems transmitting clean data (flickering, hanging colors, etc), I suggest another change here: Connect the arduino to the first LED. Use a twisted pair of a cat 5 ethernet cable to connect ground and data out of the arduino to ground and data in of the led strip directly. Keep the twist of the pair and dont exceed 0,5m length. Use another single wire to connect the 5V following the same path. Keep the 330 ohm resistor and the schottkys near the LED. This is adressing the issue that the WS2812 (and -13) data protocol has tight timing requirements and is affected easily by the signal degrading effects of long transmission lines.

I hope i do not frighten you with all that information, keep trusting your abilities. And dont hesitate to ask, if you got a problem