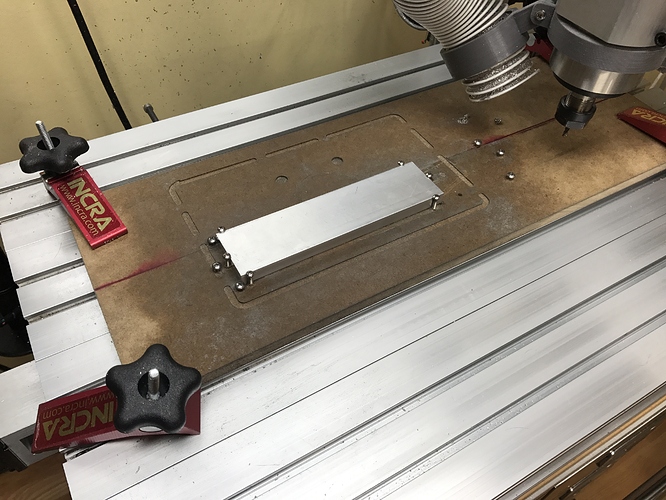

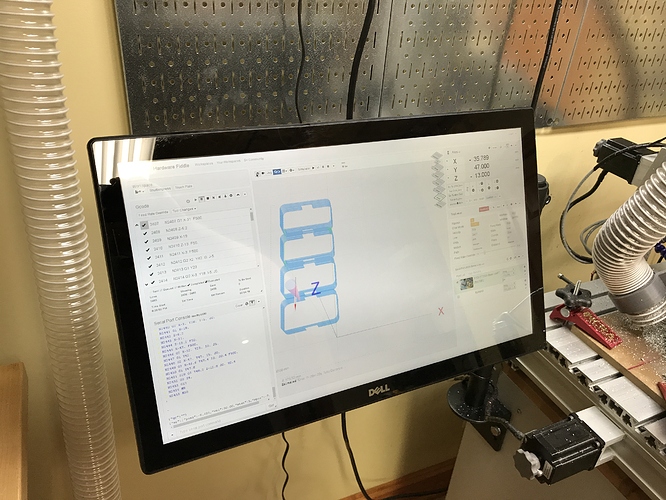

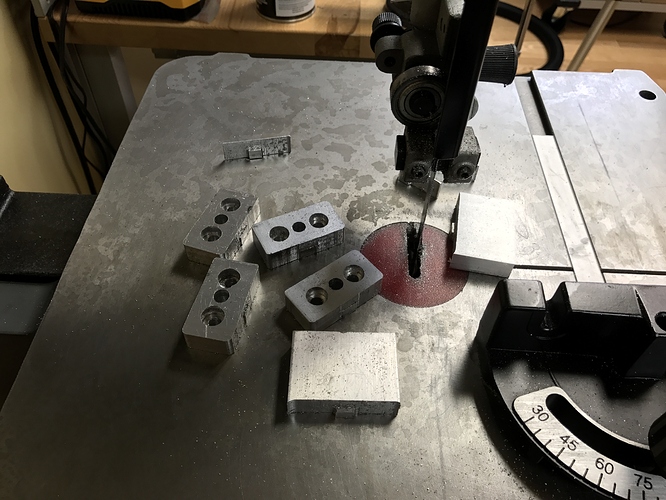

I had to add another pre-run checklist item last night. My x-axis coupler came loose mid job. I was able to stop it before it ruined the stock, and then I was able to regenerate the gcode for just the things it missed. The parts came out pretty good, there is just enough play on the spindle that when cutting around the tabs it seems to bite in to the part slightly. Not a show stopper by any means. These parts are for mounting the actuators to my sim racing motion rig. I cut them with a 4mm end mill at 500mm/m at 9000rpm, with a 0.6mm cut depth. The parts are 12.5mm thick, so it took a while…

Very nice to see a real project realized. But why u r not brave and use more feed and test ur endmill?