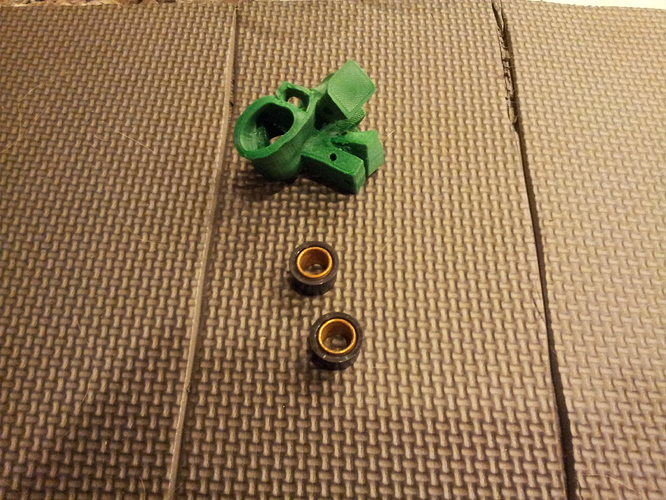

I had some problems with stress cracks and I am reprinting everything in abs. Now that I have access to a printer that will print ABS again. I ran into the same problem Ashley did, removing the brass bushings. I dunked the whole thing in boiling water for 20 seconds and it was surprizingly easy to twist with plyers and get them out. I tested and they slide okay, but did I ruin the bushings? Did it exude the oils? I can’t tell just by looking at them.

You should be able to restore the lubricant in it. Just dump them in oil. I would try thick grease and put the container in the hot water. Just dry them first

Be careful with heat. The inner section is epoxy potted into the outer housing. The epoxy is what forms the spherical joint. I learned the hard way once not to heat them with a torch to press them in. The epoxy all cracked and fell out.

Warm water should not damage the epoxy.

But might deposit plastic residue on the inside bronze surface when boiled. So I think a light cleaning of the inside, and a re-oil job will do the trick.

Thanks guys! I thing I will try the heat gun on the next set.

Be careful with a heat gun. Boiling water will only go to 100c whereas a heat gun gets much hotter. There are 2 stages to damage. If you reach the glass transition temperature, the epoxy will actually yield/bend permanently. If you heat it with a torch, you will probably break down the epoxy. It’s a thermoset, so you can’t really reflow it, it breaks down at high heat. Glass transition is just a weird relaxation/mobility of the bonds. Hope that helps