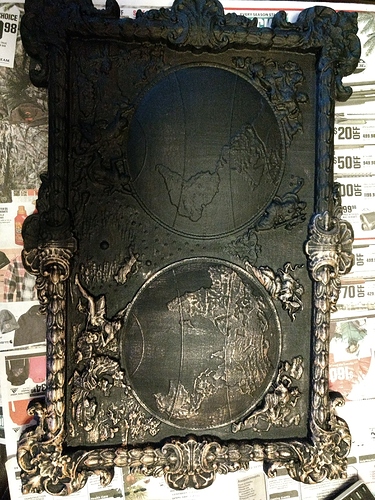

I guess nobody else shares their carving projects on here? I sort of feel like a lone wolf. One for the new year anyway. Same process in foam board. 13 hours on the machine for this one!

I was wondering why that was myself. I thought I might be doing something wrong

I couldn’t get that cut to come out right.

I’ve been trying to cut some furniture pieces in 3D: Crown Moldings, cornice boards, valences, acanthus leaf designs, corbels, mantles & column design. Have you done any of that? There’s an stl corbel on Thingiverse I was trying to cut.

Keep sharing!

Yes Keep Sharing!

@George_Allen I’m not sure how much of that is possible on a 3 axis setup without doing some fancy model slicing. What problems did you have with the, I’m assuming the archangel cross?

@Jack_Daugherty Please keep sharing. I’m not sharing because I haven’t made anything and I’m living vicariously through your projects until I have some time. I made one thing with my OX over a year ago and then decided I needed to add a laser and dust boot. Well, one year later and I haven’t finished it yet. When I do, I promise I will post.

@Jack_Daugherty hey Jack,

Sorry I haven’t gotten back sooner. Yes, they would be easier with a multi axis machine, but most can be run simply by 2-sided machining.

@Jack_Daugherty I ran some things using Meshcam, which should work, but right now I’m getting some problems with the program crashing on the stl files. I got pretty good results from some of the reliefs:

Or my work moved

I think I may have finally figured out how to cut stl files on Fusion, but I’m wary of using it b/c every time I

Run Fusion the tool head begins by burying into the table.

@George_Allen I guess I have it easy by using Cut3D and V-Carve Pro. I started learning 3d modeling years ago, and quit before I ever got any good at. There was so much to try to learn, and I knew no one else that was doing it. I had so many questions, and I just became overwhelmed and frustrated by all of it.

Now there are 100’s of how to videos available everywhere. There are also 3d models for sale so cheap that just about anyone can afford to buy them and start carving.

So good job on these, and good job on getting into the CAD/CAM side of it, and learning how to do it. Hope you keep at it, and get it figured out.

Which kind of foam is it?

@Jack_Daugherty , please keep posting.

having been part of several communites, I can tell you; readers are from very differents backgrounds. some doing 3D print, lasercuting as a hobby to prove themself then can overcome the challenge, but their creativity and software skill, not matching their excellence in mechanic, electronic, physic, …

It’s a little intimidating.